Apparatus, method, and system for diagnosing reductant deposits in an exhaust aftertreatment system

A technology for exhaust after-treatment and reducing agent, which is applied in the direction of electronic control of exhaust treatment devices, exhaust devices, exhaust treatment, etc., can solve the problem of NOx reduction efficiency, operational performance impact, and engine exhaust after-treatment system hindering operation. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

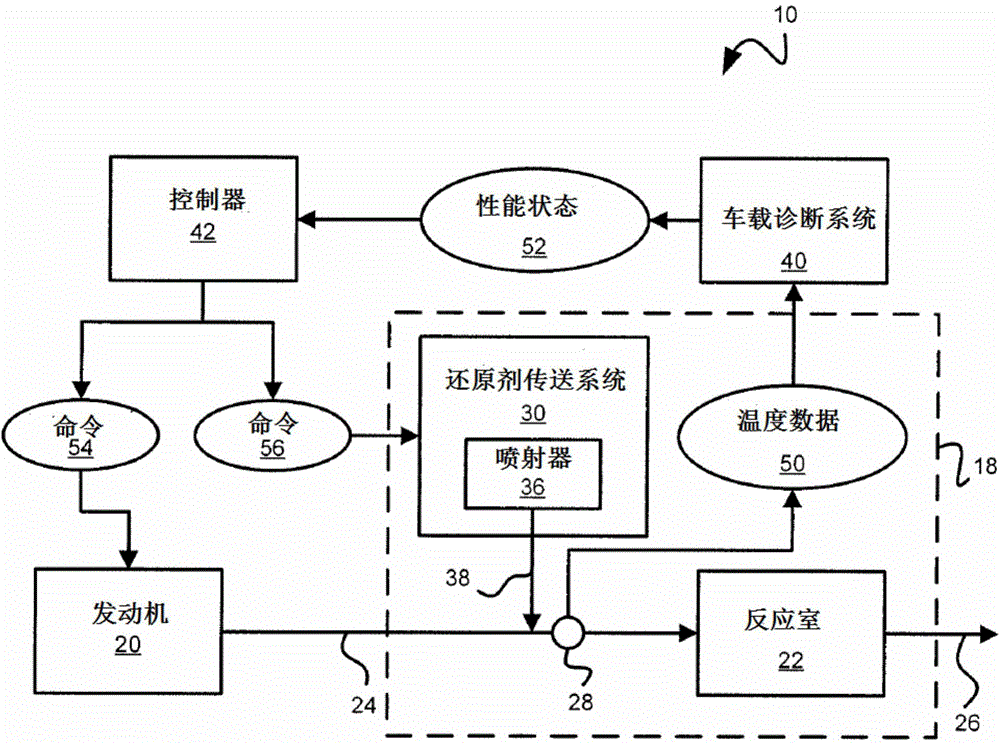

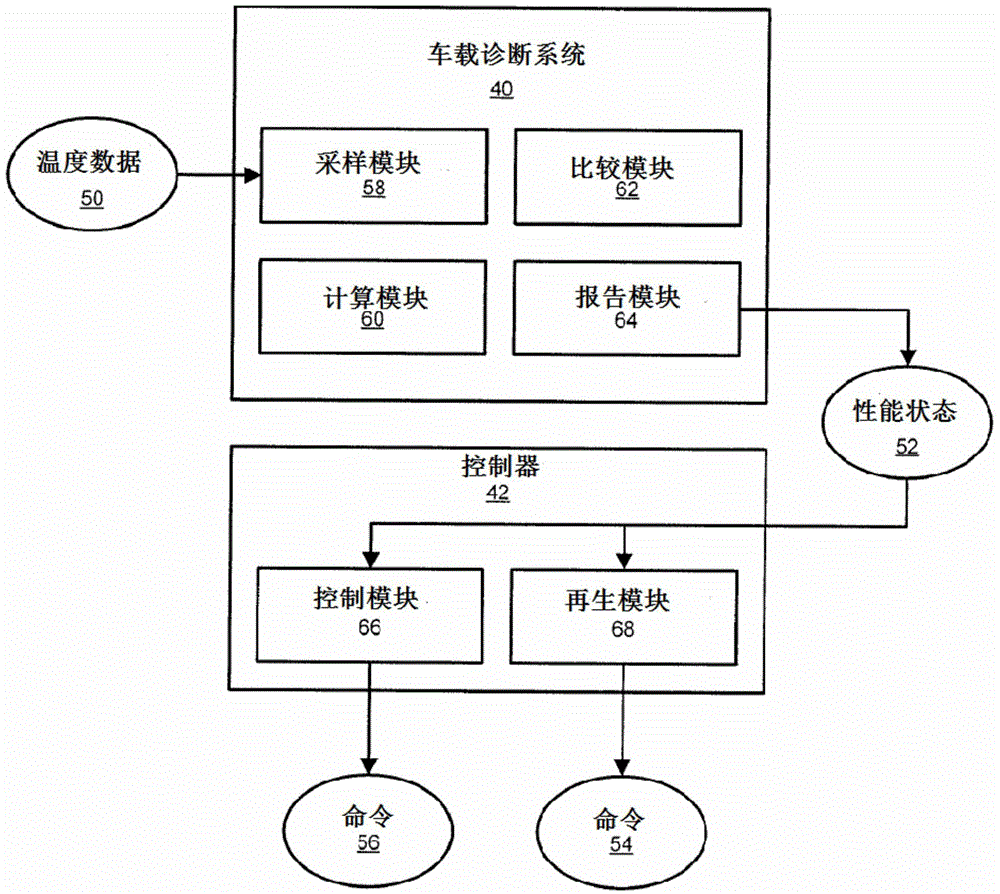

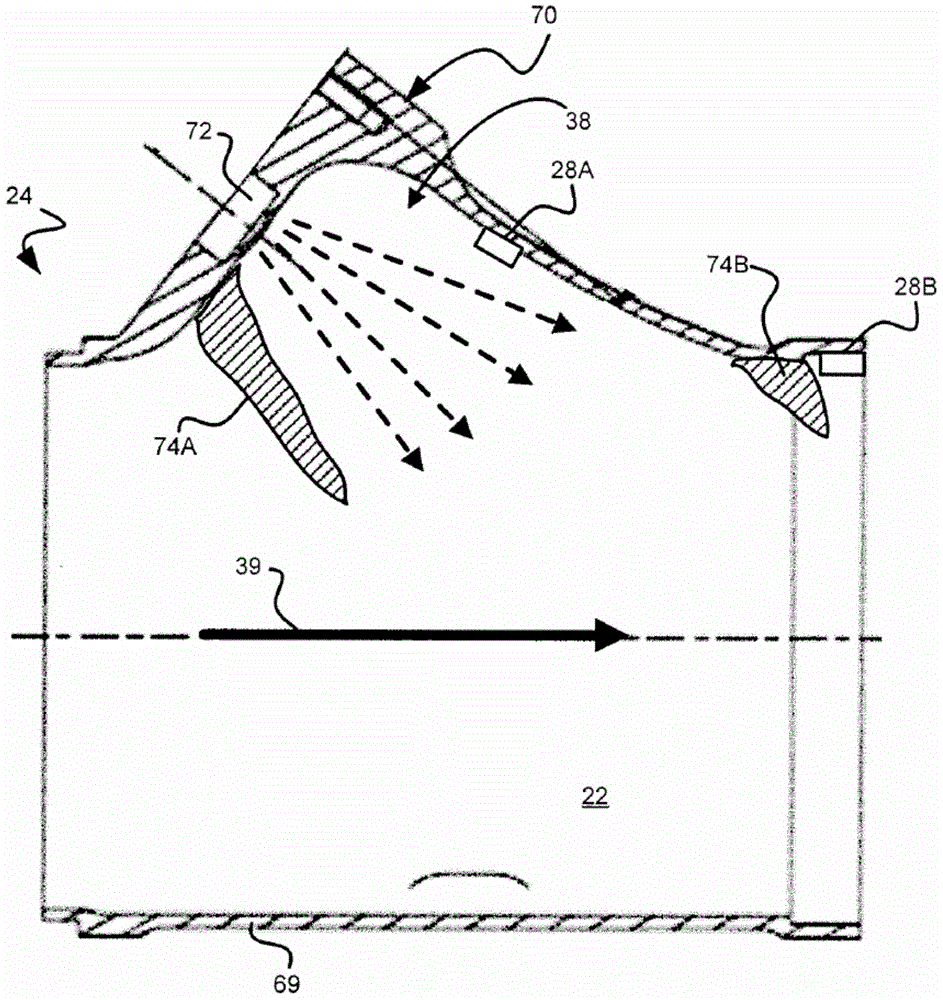

[0035] figure 1 One embodiment of an internal combustion engine system 10 is shown. Major components of the system 10 include an internal combustion engine 20 and an exhaust aftertreatment system, which may include a selective catalytic reduction (SCR) system 18 . The SCR system 18 includes a decomposition or reaction chamber 22 in which catalytic processing occurs. Reaction chamber 22 may communicate with internal combustion engine 20 , receiving exhaust gas via exhaust line 24 . The reaction chamber 22 may include any of a variety of catalysts, such as an SCR catalyst, and is configured to reduce nitrogen oxides in the presence of ammonia, which may be obtained from the reduction of a reducing agent, such as aqueous urea.

[0036] The internal combustion engine 20 may be a compression ignition engine, such as a diesel fueled engine, or a spark ignited internal combustion engine, such as a gasoline fueled engine operated on a tilt. Fuel and air are combusted within a compr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com