Ball-shaped dynamic drying machine

A dryer, spherical technology, used in non-progressive dryers, dryers, drying solid materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

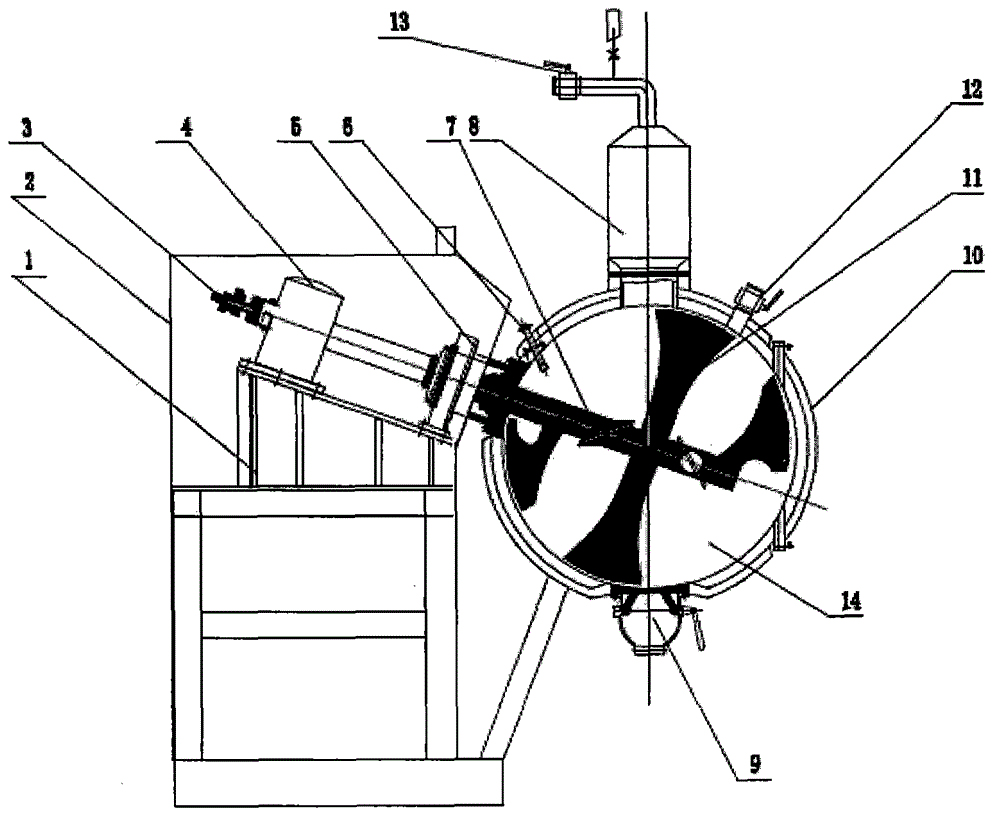

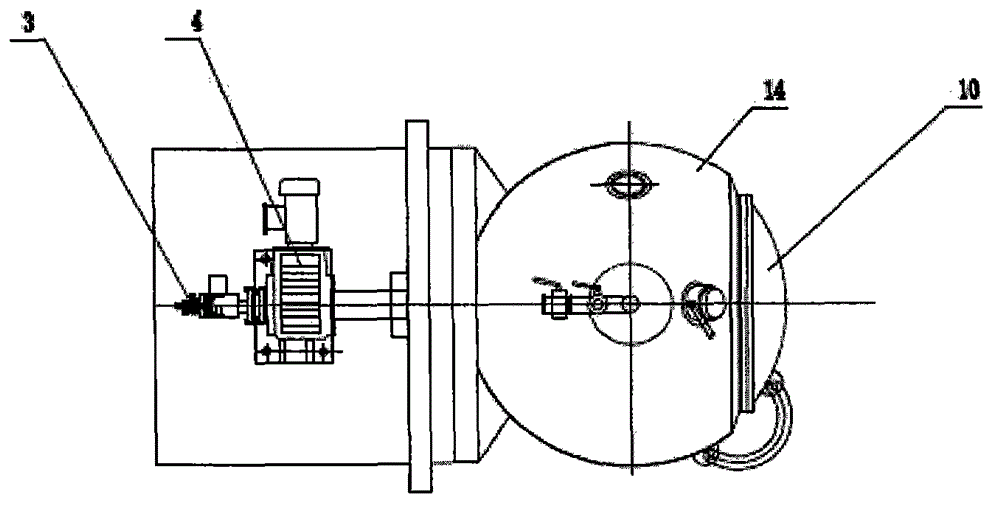

[0006] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0007] in the attached figure 1 Among them, this equipment is mainly composed of a spherical cavity 14, a paddle rotor main shaft 7, a spherical segment-shaped quick-opening front door 10, a catcher 8, a main shaft seal 5, a motor and a reducer 4, a rotor heating and rotating seal 3, a bracket 1 and Nozzle 9,12,13 constitutes, and support and speed reducer are coated with outer cover 2. The working principle is: the dried wet material is vacuum sucked into the spherical cavity 14 through the feed port 12, the paddle rotor 7 in the spherical cavity rotates 360 degrees through the motor and the reducer 4, and the paddle 11 flips and scrapes the material. The rotor and the cavity are isolated by the main shaft seal 5, the evaporated gas enters the vacuum system through the outlet 13 through the collector 8, and the dry powder of the dried materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com