Oil-immersed transformer cooling fin

A technology for oil-immersed transformers and heat sinks, applied in transformer/inductor cooling, laminated components, heat transfer modification, etc., can solve problems such as unfavorable applications, inability to carry out punching design, cumbersome processes, etc., and achieve easy processing. , Improve the convective heat transfer efficiency, the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following uses a triangular pyramid longitudinal vortex generator as an example to illustrate the present invention, but it is not used to limit the scope of the present invention.

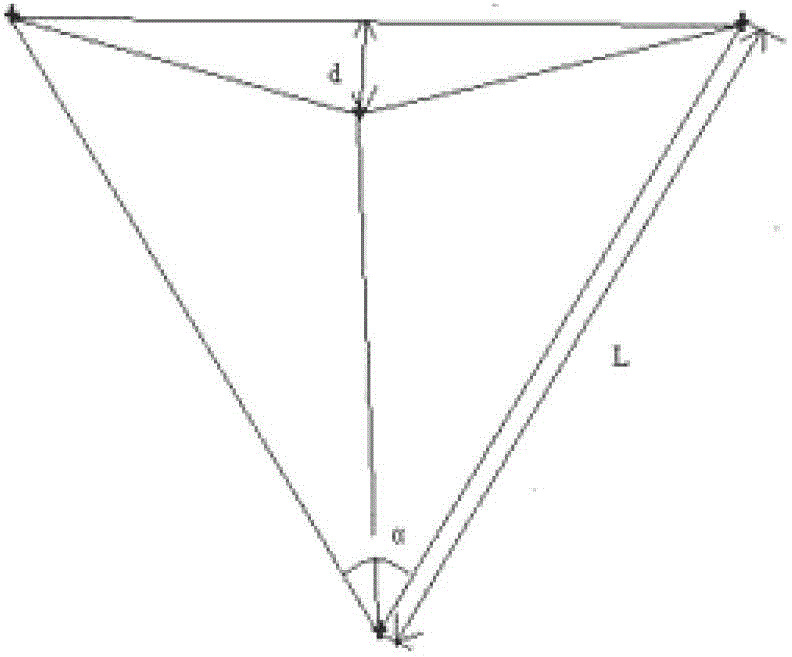

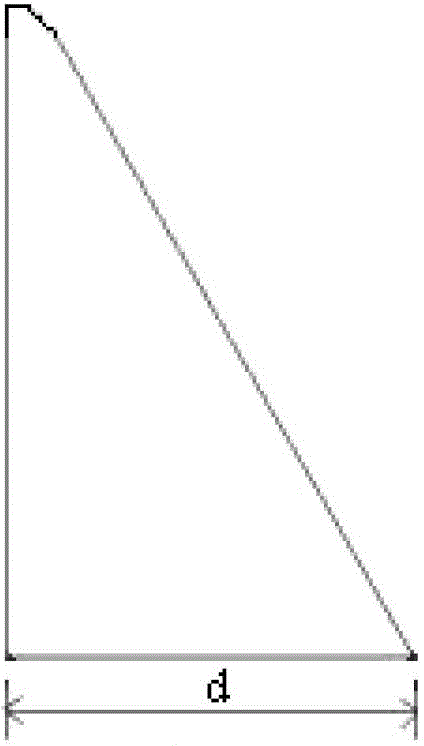

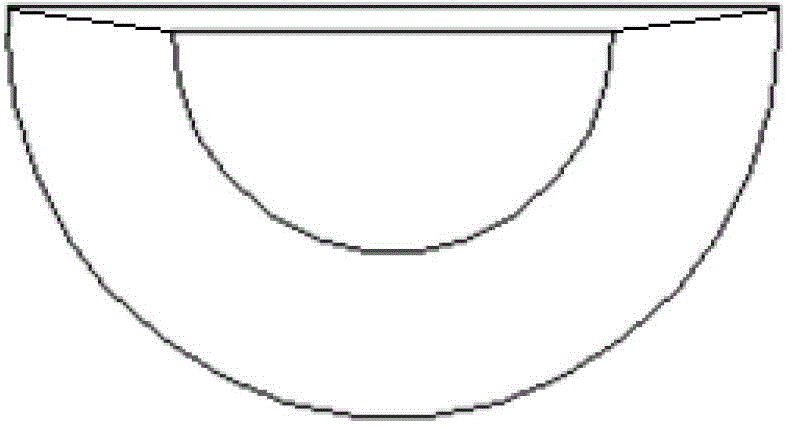

[0024] see Figure 1-2 , Figure 7 , the present invention takes a selected triangular conical longitudinal vortex generator as an example to carry out numerical calculation on the working condition of natural air convection of oil-immersed transformer cooling fins. figure 1 A number of three-dimensional protruding spoiler structures obtained by stamping, embossing and other processing methods in the manufacturing process of oil-immersed transformer heat sinks are given in . A certain spoiler structure is a longitudinal vortex generator. The spoiler structure It is a triangular cone, and the bottom of the triangular cone is seamlessly connected or integrated with the heat sink of the oil-immersed transformer. The parameters used in the numerical example are as follows: the length and w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com