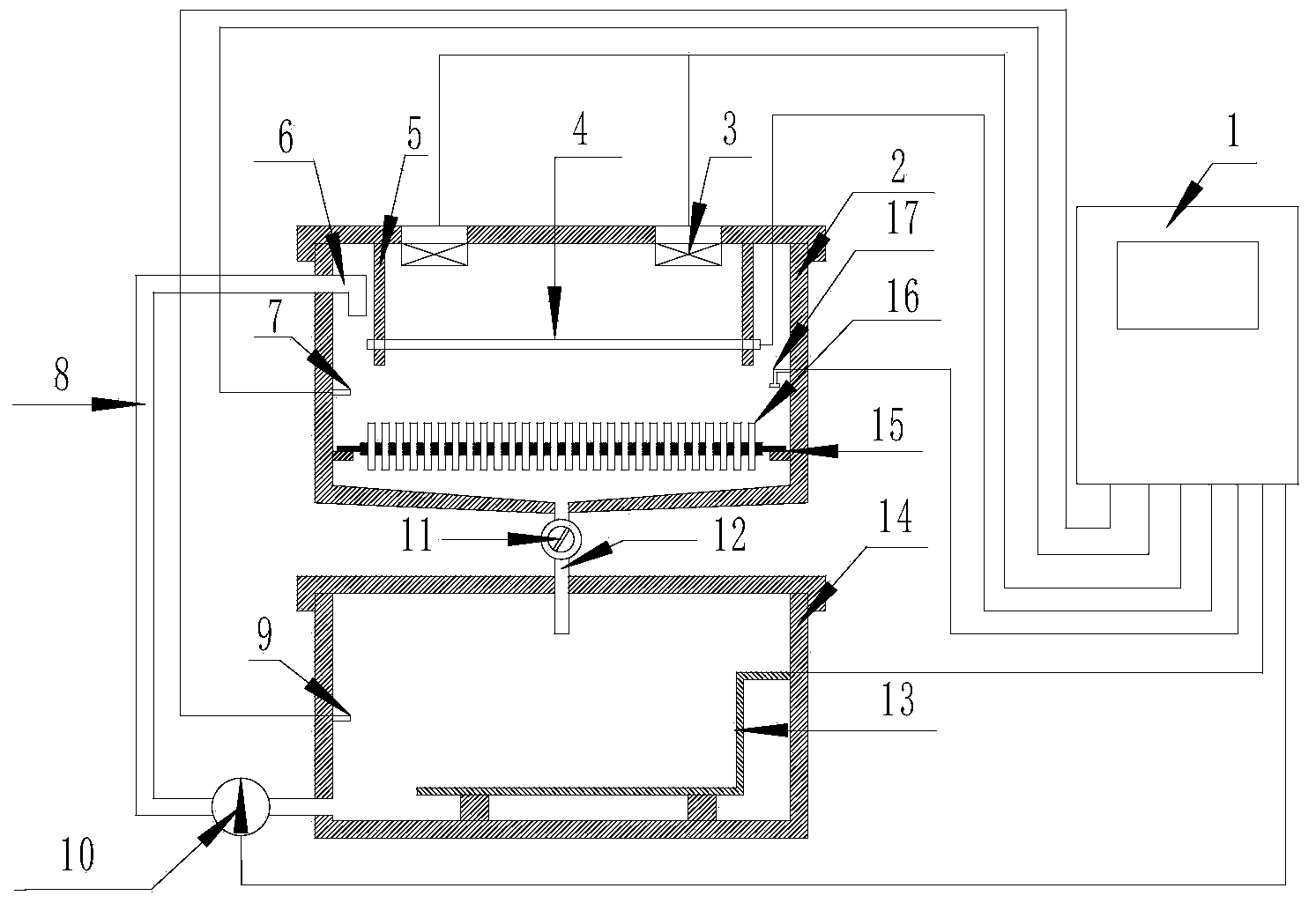

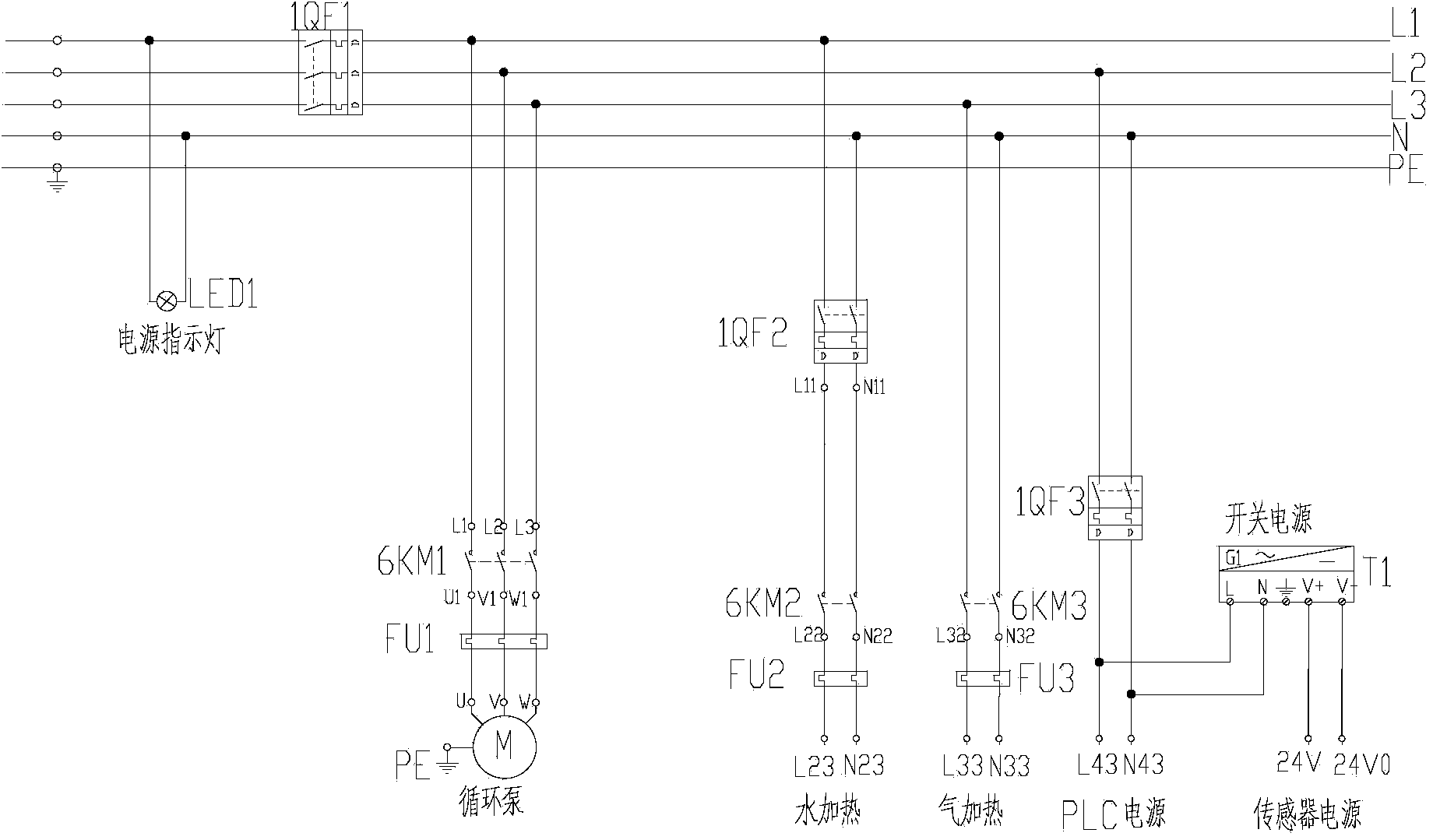

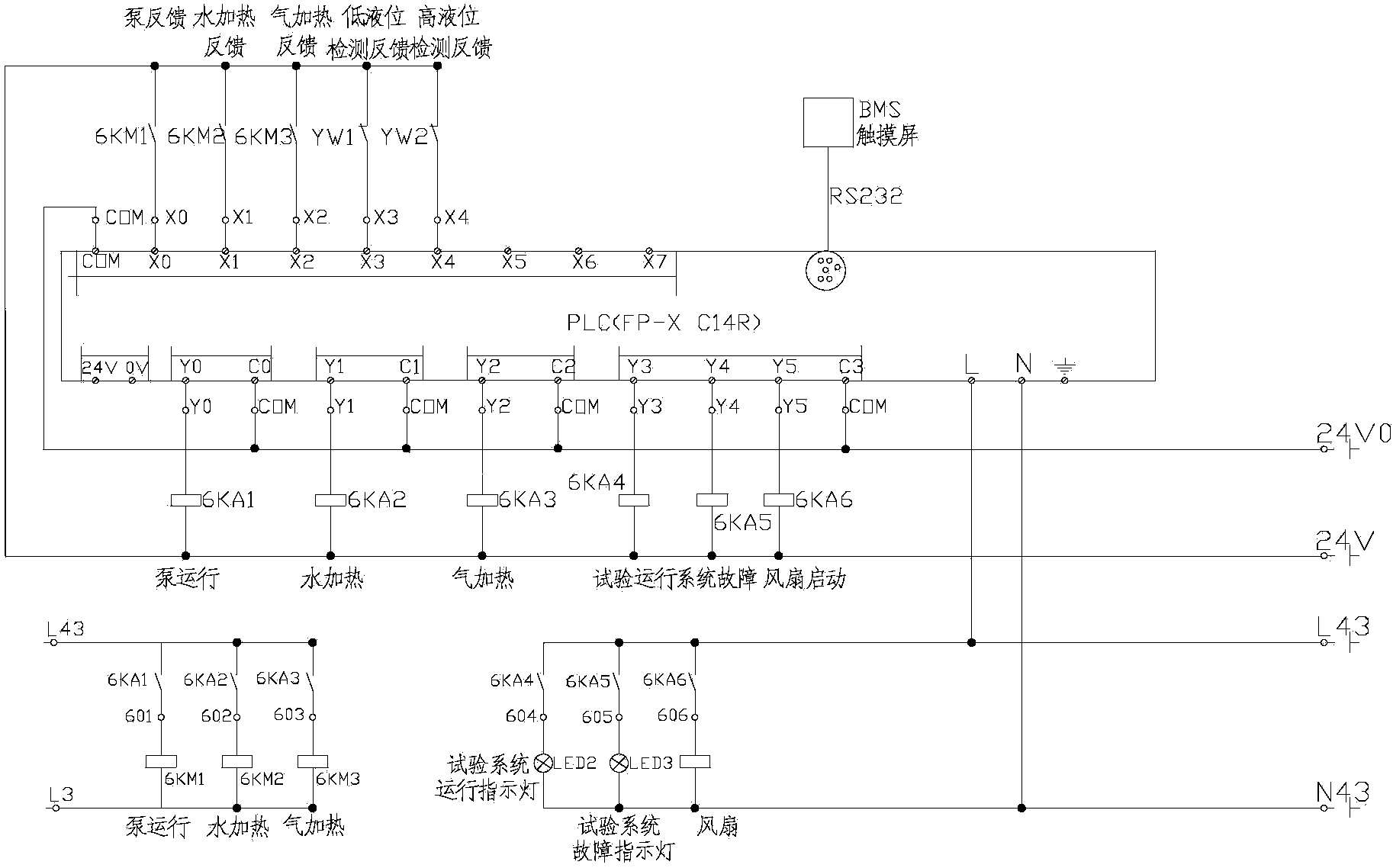

Periodic soaking accelerated corrosion test system for metal material and metal protective coating and application thereof

An accelerated corrosion test, metal protection technology, applied in the direction of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve the problems of no heating of corrosive medium solution, inaccurate temperature detection system, uneven air heating temperature, etc., to achieve disassembly It has the advantages of convenient maintenance, improved test efficiency and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0053] Select two kinds of aluminum alloys 5083 and 6061, 10 parallel samples of each aluminum alloy, sample size: 200mm×100mm×5mm, grind to 2000# step by step with SiC water sandpaper, and then use mechanical polishing until no obvious scratches, and then use After rinsing with deionized water for 10 minutes, dry the remaining droplets on the surface with a hair dryer.

[0054] Put the pretreated sample into the sample holder and put it into the test tank. The corrosion medium solution uses 3.5wt% NaCl solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com