Parachloroaniline imprinted polymer membrane electrode, and preparation method and application method thereof

An imprinted polymer, p-chloroaniline technology, applied in the direction of material electrochemical variables, can solve the problems of cumbersome operation, long detection period, low selectivity, etc., and achieve the effect of high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

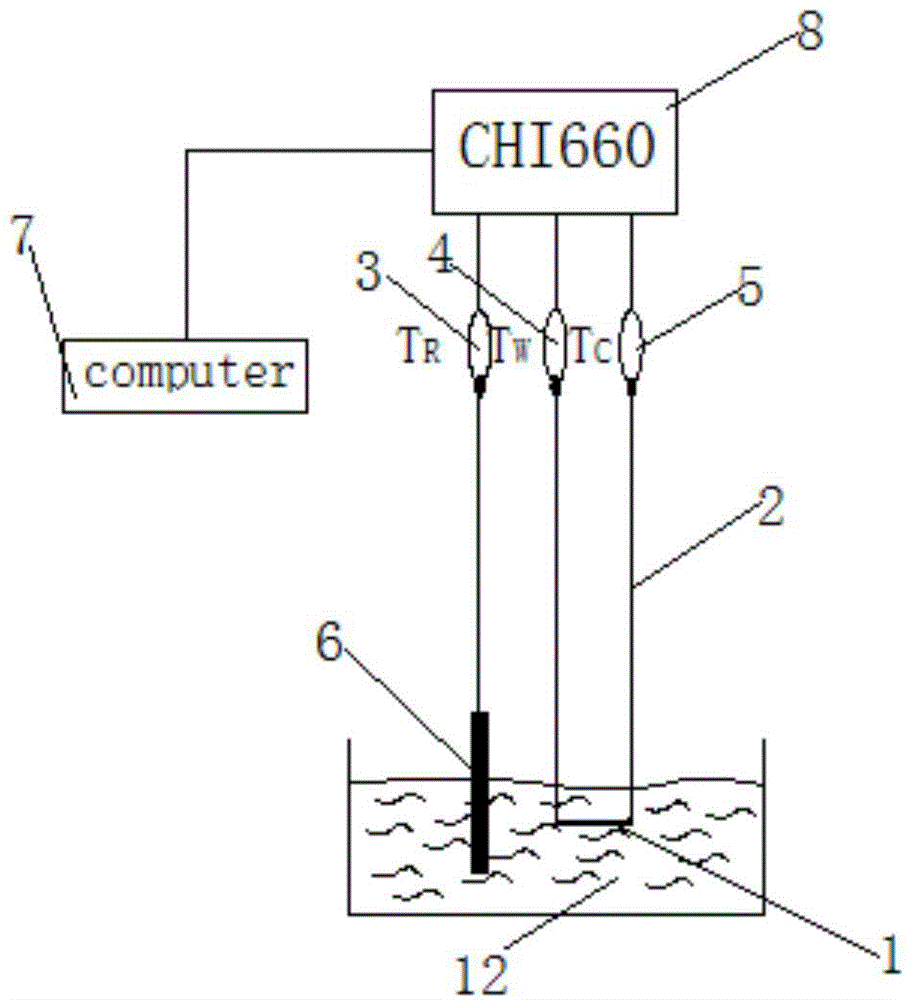

[0052] The preparation method of the p-chloroaniline imprinted polymer membrane electrode of the present invention is specifically implemented according to the following steps:

[0053] Step 1, prepare graphite electrode,

[0054] Step 1.1, cut the graphite rod into small pieces of 2 to 4 cm, and boil for 30 to 50 minutes in a paraffin solution;

[0055] Step 1.2, cut 5-10cm of copper wire, polish the copper wire at 1 to 3cm at both ends, wind the two copper wires on both ends of the graphite rod, and fix the copper wire and graphite rod together to make Graphite electrode

[0056] In step 1.3, polish the graphite electrode prepared in step 1.2 with weighing paper, and then ultrasonically wash it with absolute ethanol and double distilled water for 5-10 minutes to remove impurities on the electrode surface, and dry it for later use.

[0057] Step 2. Prepare p-chloroaniline imprinted polymer film on graphite electrode:

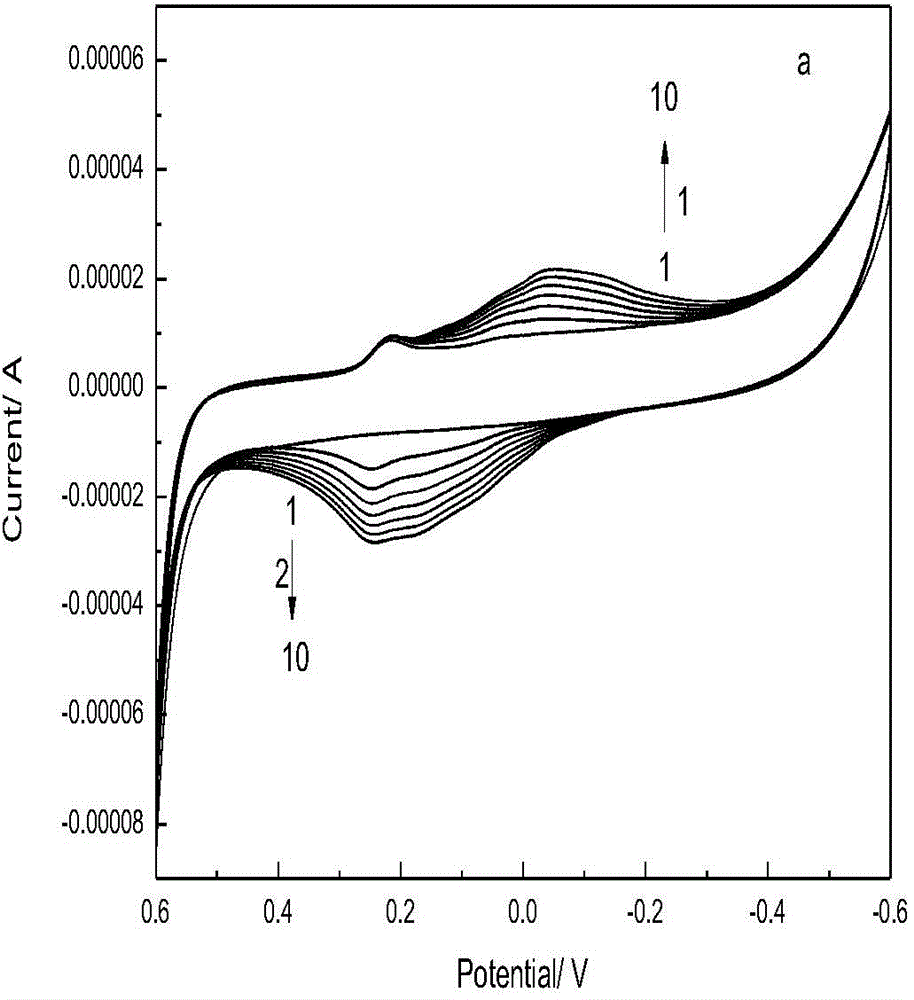

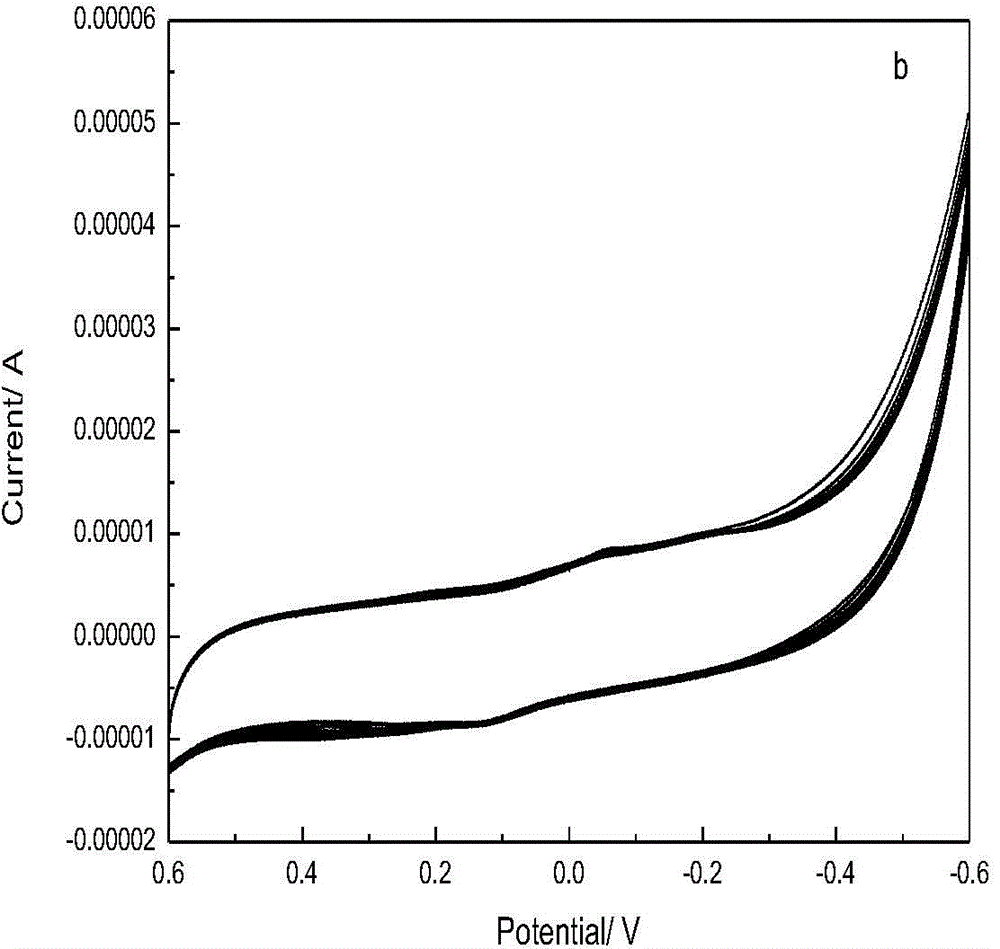

[0058] Step 2.1: Place the treated graphite electrode in a PBS buff...

Embodiment 1

[0105] The preparation of chloroaniline imprinted polymer membrane electrode is carried out according to the following steps: Step 1, preparation of graphite electrode, first cut the graphite rod into 2cm pieces, and boil it in paraffin solution for 30min; then cut 5cm copper wire, and cut the copper wire into two pieces. The end 1cm is polished clean, two copper wires are respectively wound around the two ends of the graphite rod, and the copper wire and the graphite rod are fixed together to make a graphite electrode; finally the prepared graphite electrode is polished with weighing paper, and then used Anhydrous ethanol and double-distilled water were ultrasonically washed for 5 minutes each to remove impurities on the electrode surface, and dried for later use.

[0106] Step 2. Prepare the p-chloroaniline imprinted polymer film on the graphite electrode: first, place the treated graphite electrode in a PBS buffer solution for deoxygenation for 10 minutes. The PBS buffer soluti...

Embodiment 2

[0111] The preparation of chloroaniline imprinted polymer membrane electrode is carried out according to the following steps: Step 1, preparation of graphite electrode, first cut the graphite rod into 4cm pieces, and boil it in paraffin solution for 50min; then cut a 10cm copper wire, and cut the copper wire into two pieces. The end 2cm is polished clean, two copper wires are respectively wound around the two ends of the graphite rod, and the copper wire and the graphite rod are fixed together to make a graphite electrode; finally the prepared graphite electrode is polished with weighing paper, and then used Anhydrous ethanol and double-distilled water were ultrasonically washed for 10 minutes each to remove impurities on the electrode surface, and dried for later use.

[0112] Step 2. Prepare the p-chloroaniline imprinted polymer film on the graphite electrode: first, place the treated graphite electrode in a PBS buffer solution for deoxygenation for 15 minutes. The PBS buffer so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com