High-speed photoelectric conversion device and assembly method thereof

A photoelectric conversion device, high-speed technology, applied in the coupling of optical waveguide, etc., can solve the problems of limiting high-frequency signal transmission, large inductance on the line, etc., to avoid signal attenuation, increase the transmission rate, and save costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

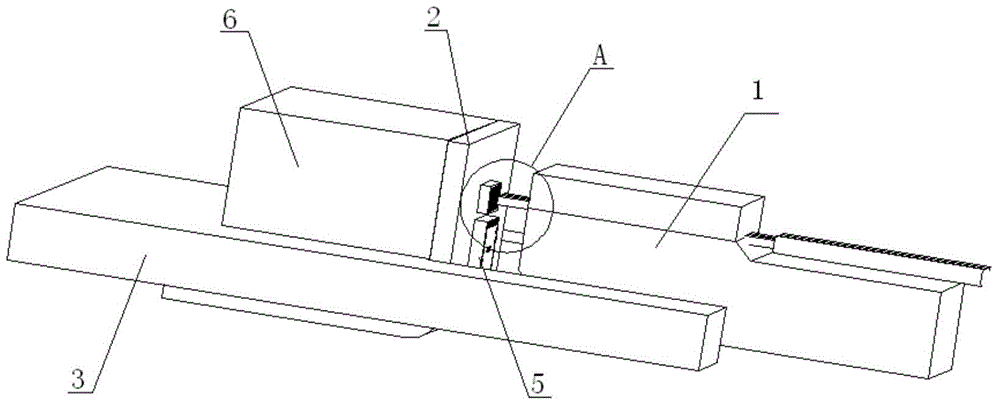

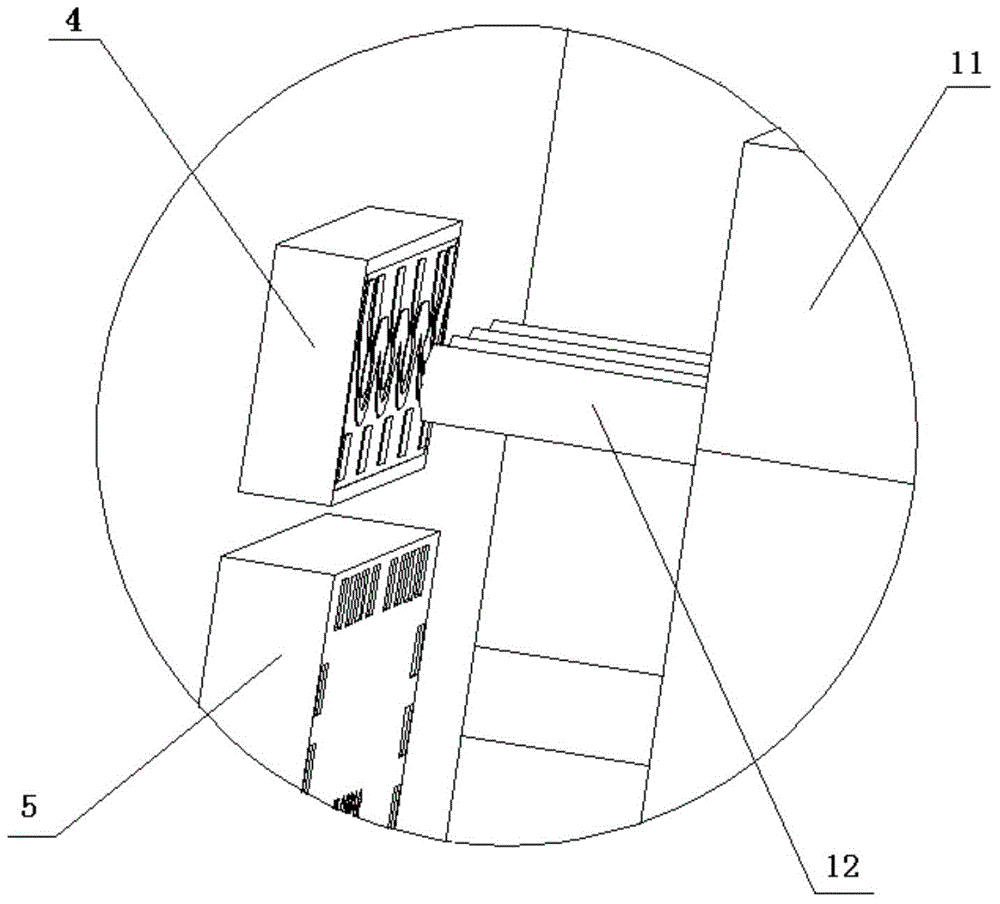

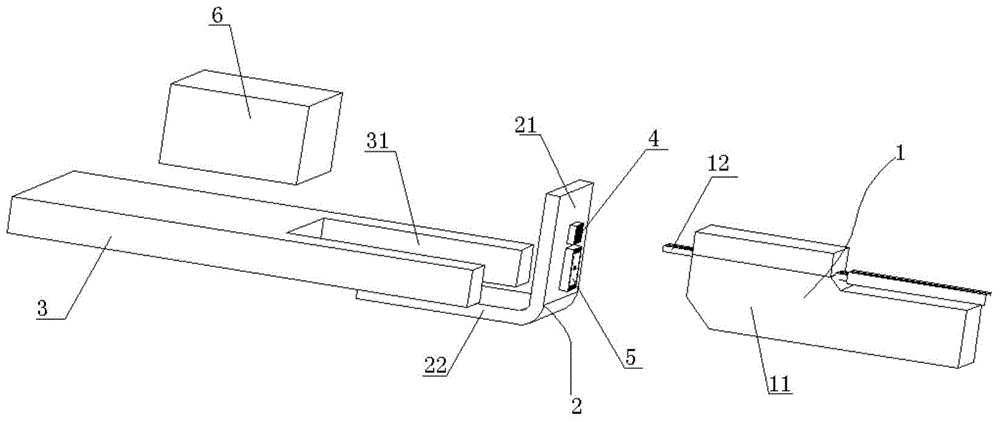

[0030] Such as figure 1 , figure 2 with image 3 As shown, a high-speed photoelectric conversion device includes an optical fiber array assembly 1, a flexible wire board 2, a PCB circuit board 3, a photoelectric chip array group 4 (such as a VCSEL chip array or / and a PD chip array), and is used to drive the The driving circuit chipset 5 and the stopper 6 of the photoelectric chip array group; the optical fiber array assembly includes a fixed seat 11 and multiple parallel optical fibers 12 that are spaced and positioned in the fixed seat; the PCB circuit board One side has a U-shaped notch 31, and the flexible cord board includes a mounting part 21 and a welding part 22 that are integrally bent at a set angle. Blocked in the notch, the welding part is attached to the bottom of the stopper and extends to the bottom of the PCB circuit board, and the welding part is electrically connected to the circuit line on the PCB circuit board, so The mounting part is installed in the no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com