Graphene capacitance touch screen and manufacturing method thereof

A technology of capacitive touch screen and manufacturing method, which is applied in the direction of electric digital data processing, instrument, input/output process of data processing, etc., can solve problems such as easy scratches and punctures of the film, malfunction of the touch screen, etc., and achieve thermal stability and Strong chemical stability, high stability, and strong user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

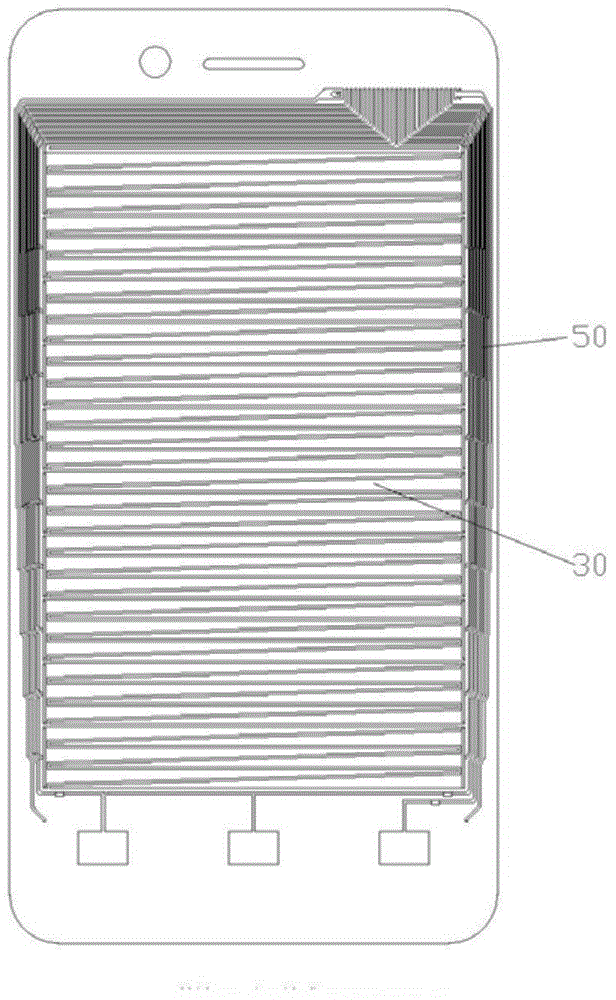

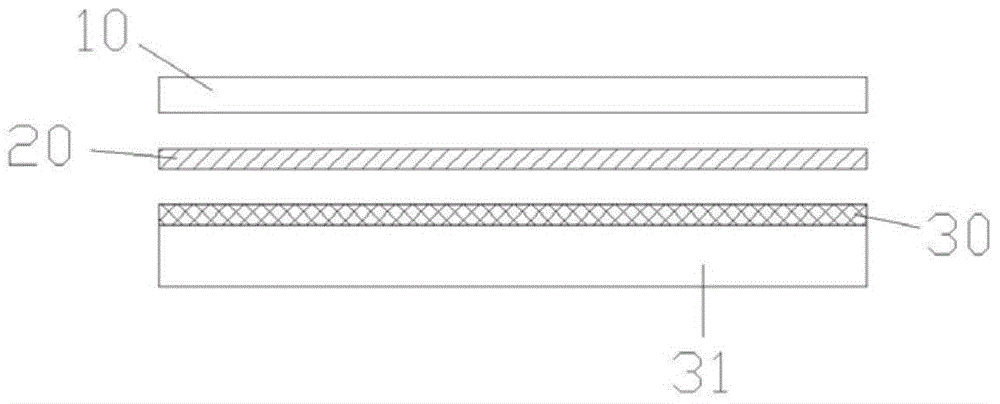

[0076] Such as Figures 1 to 14 As shown, a graphene capacitive touch screen 100 includes a cover layer 10, an OCA optical adhesive layer 20 and a graphene transparent conductive film layer 30, wherein the OCA optical adhesive layer 20 is arranged between the cover layer 10 and the Between the graphene transparent conductive film layers 30, the cover layer 10 is made of PC material.

[0077] A circuit layer 40 is also arranged on the lower surface of the graphene transparent conductive film layer 30 .

[0078] An electrode layer 50 is arranged around the circuit layer 40 , and the electrode layer 50 is printed with silver paste material. The electrode layer 50 is used to lead out the circuit layer 40 .

[0079] During work, a low-voltage AC electric field is formed in the graphene transparent conductive film layer 30, and when the user's finger touches the surface of the graphene capacitive touch screen, a coupling capacitance will be formed between the finger and the graphen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com