Welding material for ni-based heat-resistant alloys, and welded metal and melded joint each using same

A heat-resistant alloy, welding material technology, applied in welding/welding/cutting items, welding/cutting medium/material, welding medium, etc., can solve the residual stress relaxation cracks, do not consider stress relaxation cracks, low Ti content, etc. problem, to achieve the effect of good creep strength and excellent welding workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

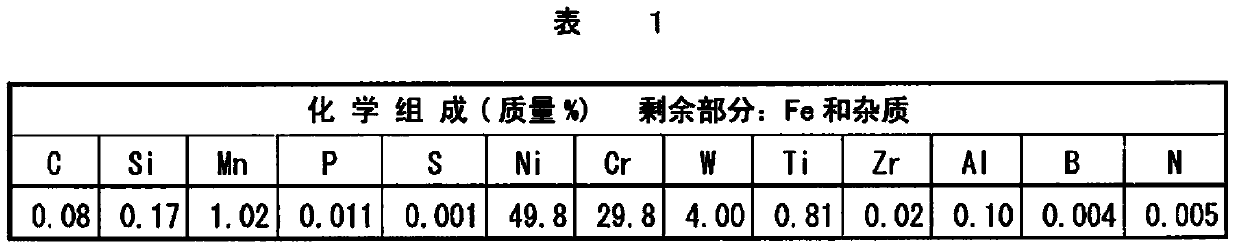

[0143] The material with the chemical composition shown in Table 1 was melted and casted in the laboratory to obtain a steel ingot. From the steel ingot, through hot forging, hot rolling, heat treatment and mechanical processing, a plate with a thickness of 12mm, a width of 50mm, and a length of 100mm was produced as the welding base material Use planks.

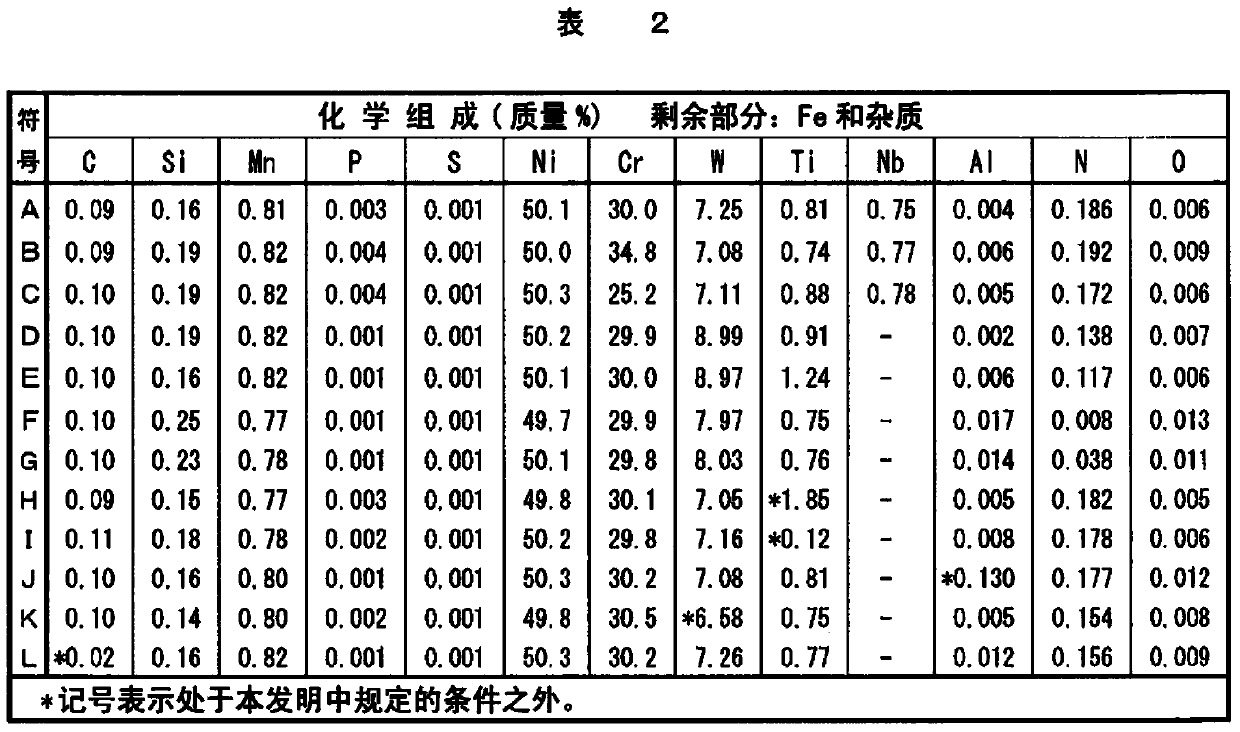

[0144] Furthermore, the materials with symbols A to L shown in Table 2 were melted and casted in the laboratory to obtain steel ingots, and from the steel ingots, a welding material with an outer diameter of 1.2 mm and a length of 1000 mm was produced by hot forging, hot rolling and mechanical processing (welding wire).

[0145] [Table 1]

[0146]

[0147] [Table 2]

[0148]

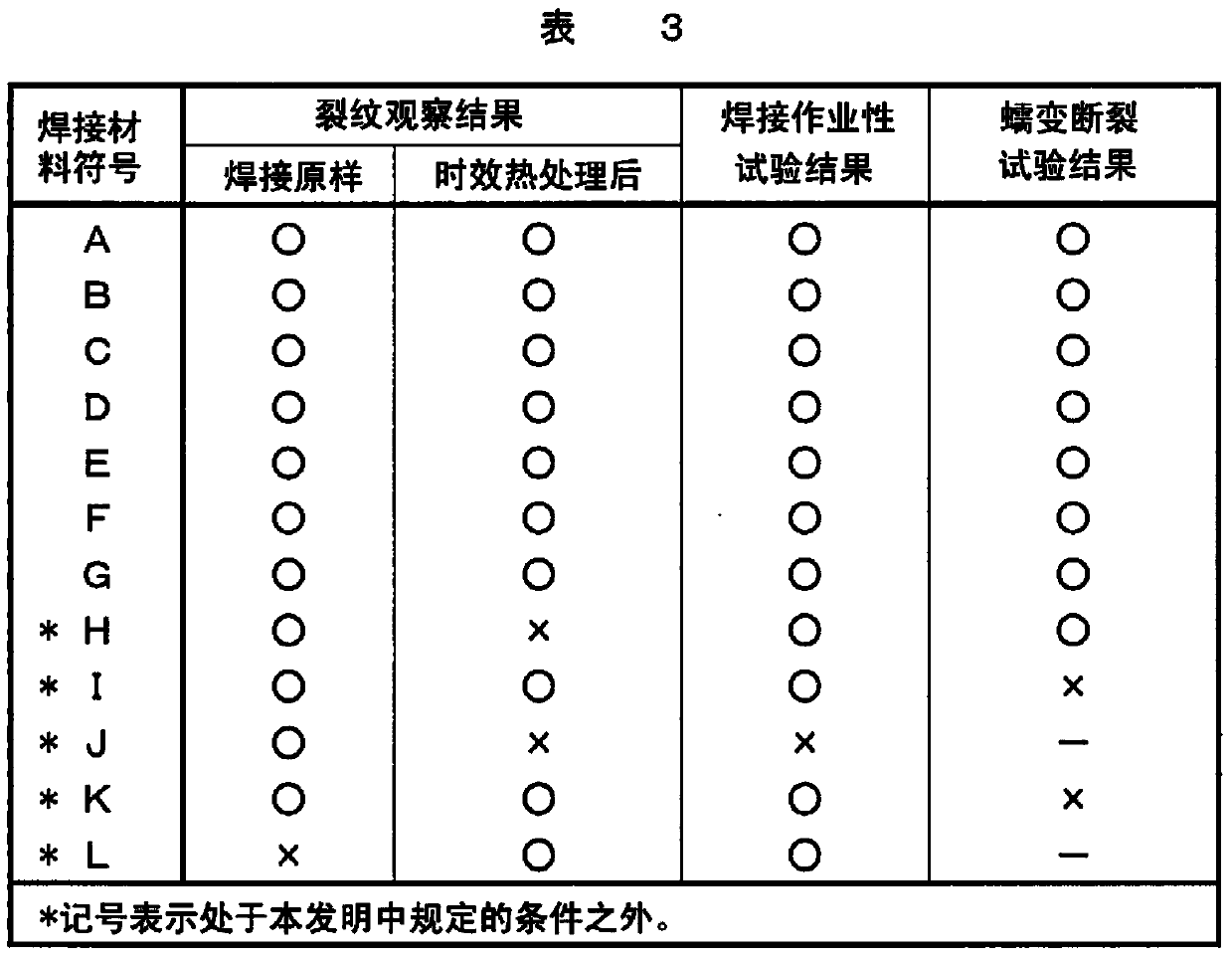

[0149] In the longitudinal direction of the above-mentioned plate for welding base material, after processing a V-groove at an angle of 30° and a height of 1 mm at the bottom edge, on a commercially available steel plate specified in JIS G3106 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com