Transfer printing film for back face transfer printing of glass or transparent film and production and usage method

A technology of transparent film and transfer film, applied in the field of decorative materials, can solve problems such as unsatisfactory contamination performance, and achieve the effects of improving mechanical and chemical properties, improving adhesion, and improving protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

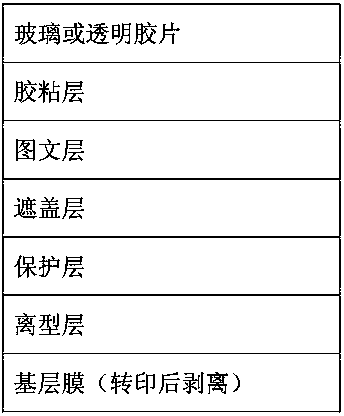

[0019] Such as figure 1 As shown, the transfer film described in this embodiment for transfer printing on the back of glass or transparent film includes a base film, and the base film is successively provided with a release layer, a protective layer, a cover layer, a graphic layer, and an adhesive layer. The adhesive layer is in contact with glass or transparent film.

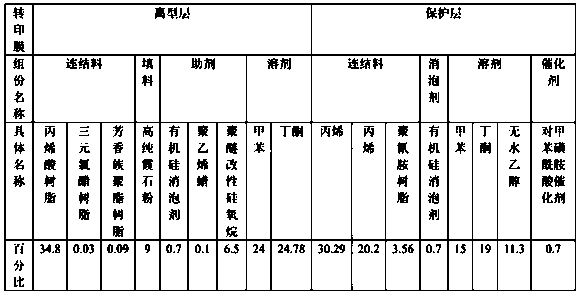

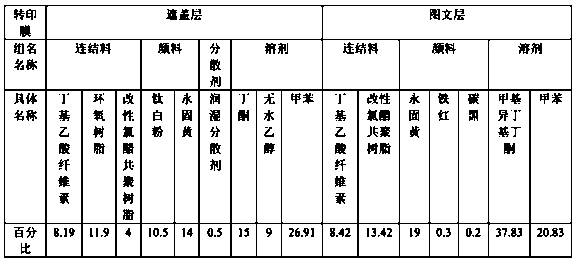

[0020] The release layer described therein is composed of a linking material, a filler, an auxiliary agent and a solvent, wherein the linking material is composed of acrylic resin, terpolymer resin and aromatic polyester resin, and the mass percentages of the three components are respectively 34.8%, 0.03% and 0.09%. The filler is composed of high-purity nepheline powder, with a mass percentage of 9%. The auxiliary agent is composed of silicone defoamer, polyethylene wax and polyether modified siloxane, and the mass percentages of the three components are 0.7%, 0.1% and 6.5% respectively. The solvent is tolue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com