Unblocking device for V groove-shaped integrated reinforced concrete feed bins

A reinforced concrete and silo technology, applied in the field of mineral processing equipment, can solve the problems of being unable to install a pneumatic vibrating hammer, hindering the decline of mineral materials in the silo, and affecting production, etc., to achieve easy maintenance and repair, reduce operating intensity, and convenient installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

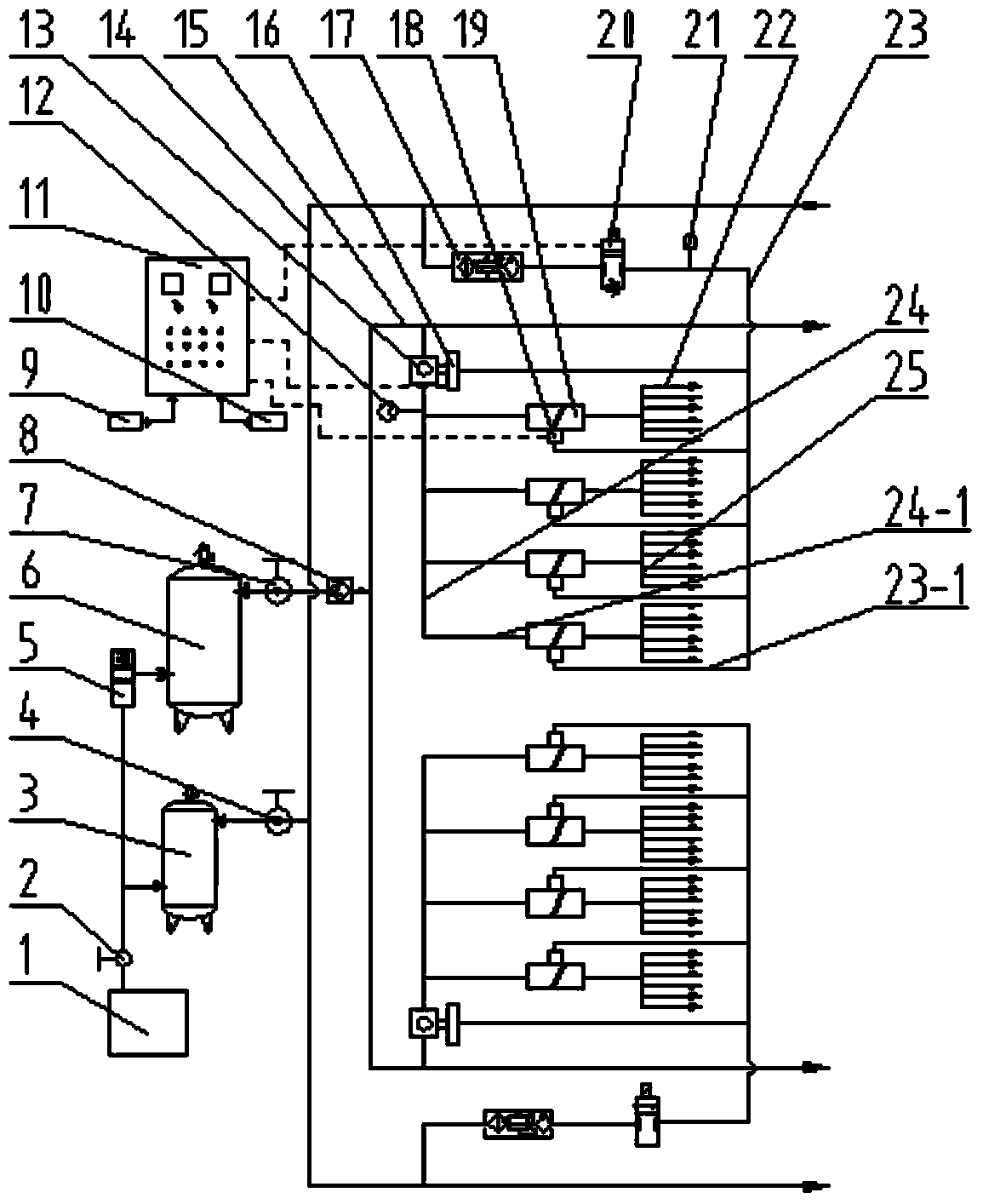

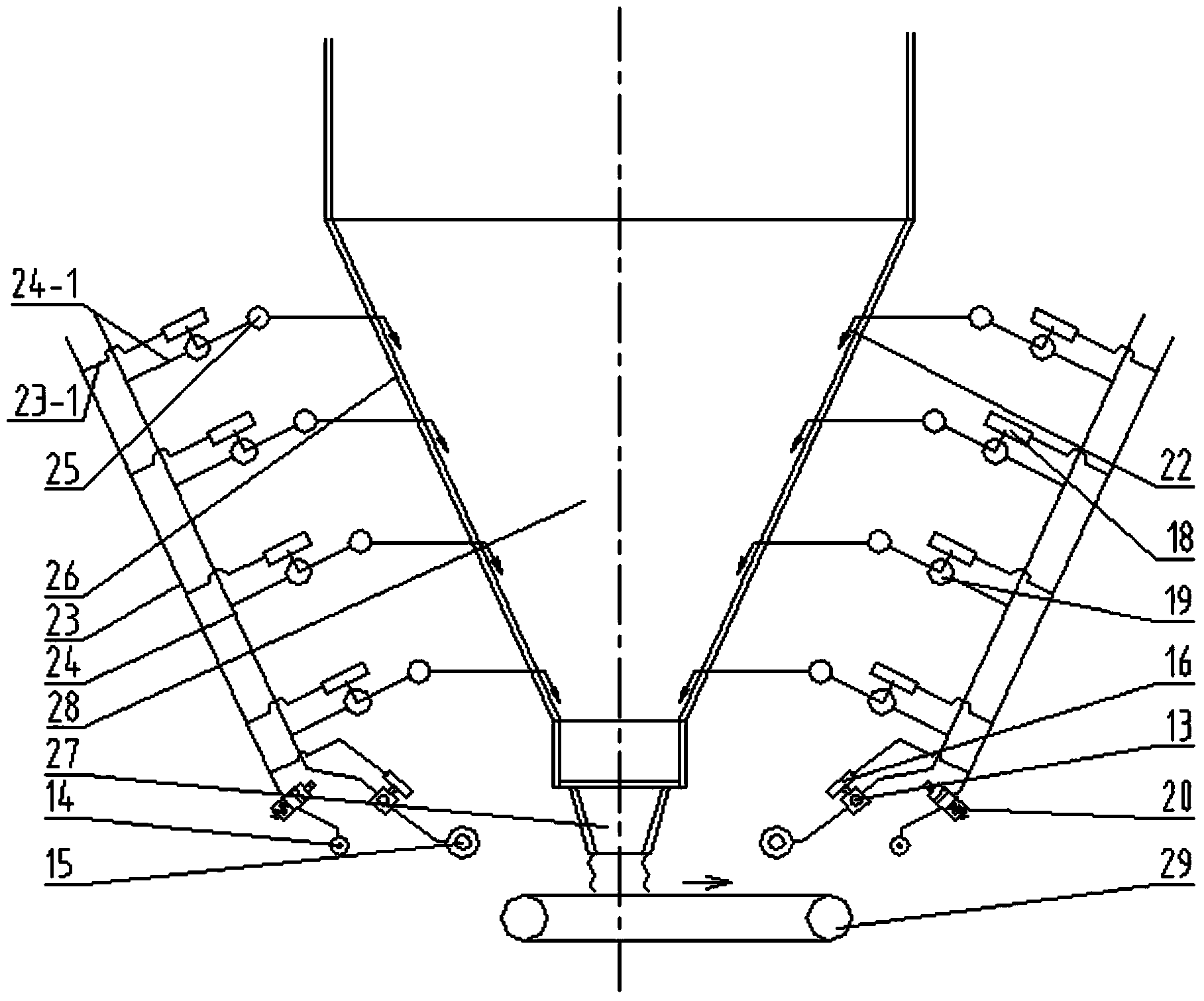

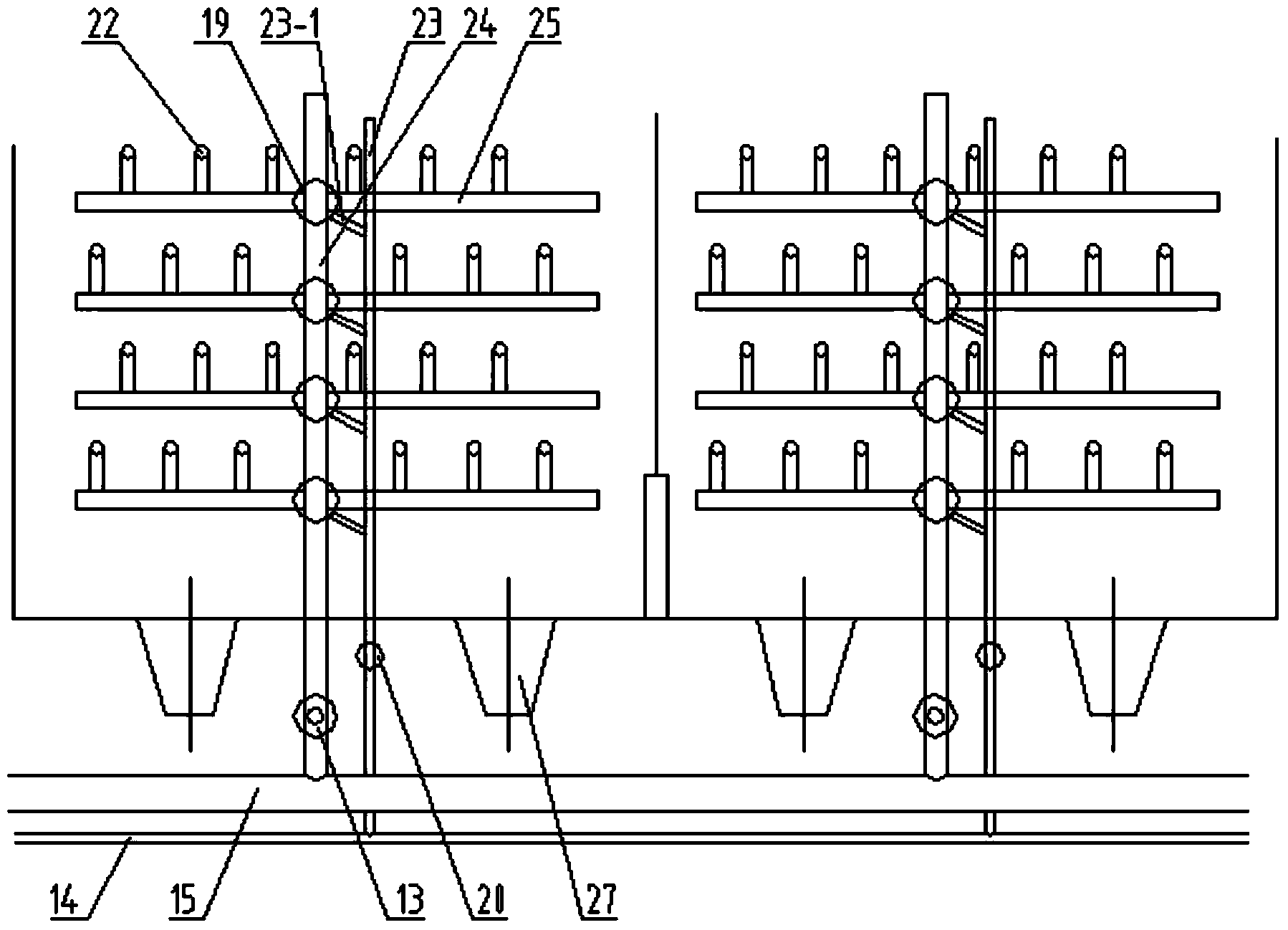

[0016] From Figure 1-Figure 3 As can be seen from the figure: a V-groove conjoined reinforced concrete silo unclogging device (abbreviated as the silo unclogging device), comprising each V-groove-shaped silo 28 of conjoined reinforced concrete, in this silo The bottom of 28 (i.e. below the silo wall 26 on the left and right sides) is provided with an inverted frustum-shaped discharge hopper 27, and a belt conveyor 29 is provided below each discharge hopper 27; it is characterized in that: the V-groove conjoined The unclogging device of the reinforced concrete silo is mainly composed of air compressor 1, air storage tank Ⅰ3 (i.e. the air storage tank for control), air storage tank Ⅱ6 (i.e. the air storage tank for flow aid), left junction box 9, right Composed of junction box 10, electric control box 11, pneumatic flow aid device, and pneumatic control device, air compressor 1 and air storage tank are installed on the foundation of the outer parts of each V-groove-shaped silo ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com