Water-based laser anti-counterfeit printing ink

A laser anti-counterfeiting and water-based technology, applied in the field of coatings, can solve the problems of lack, difficulty in imitation, and high efficiency, and achieve the effects of improving cost performance, improving the scope of use, and improving service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

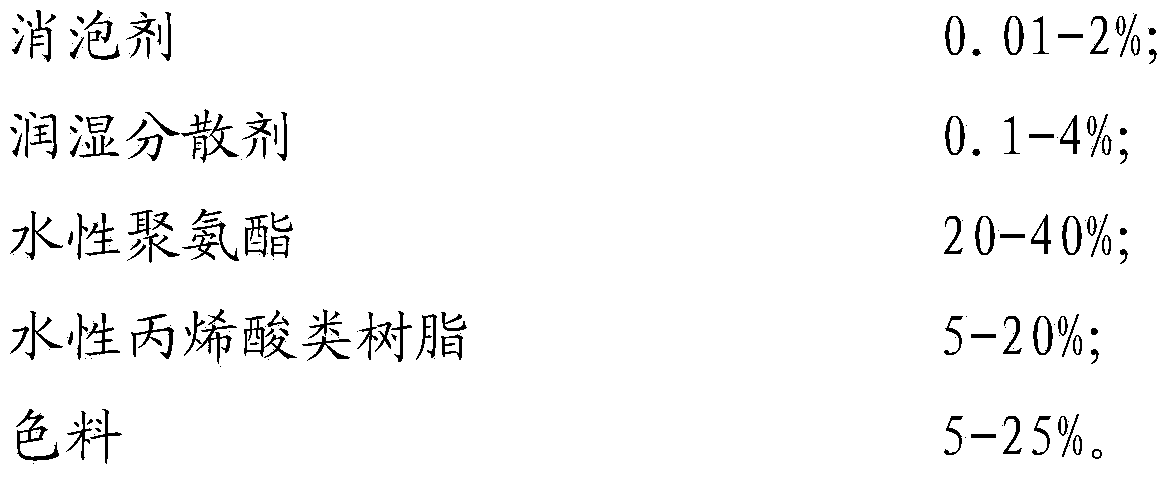

[0032]

[0033] The preparation method is:

[0034] First add deionized water and alcohol into the reaction vessel, start the disperser and mix thoroughly at 500-600r / min, then slowly add other materials while stirring according to the discharge sequence, after dispersing for 50 minutes, filter and pack with 200-mesh filter cloth for use. Because no colorant is added in the present embodiment, what obtains is water-based laser anti-counterfeiting ink varnish.

Embodiment 2

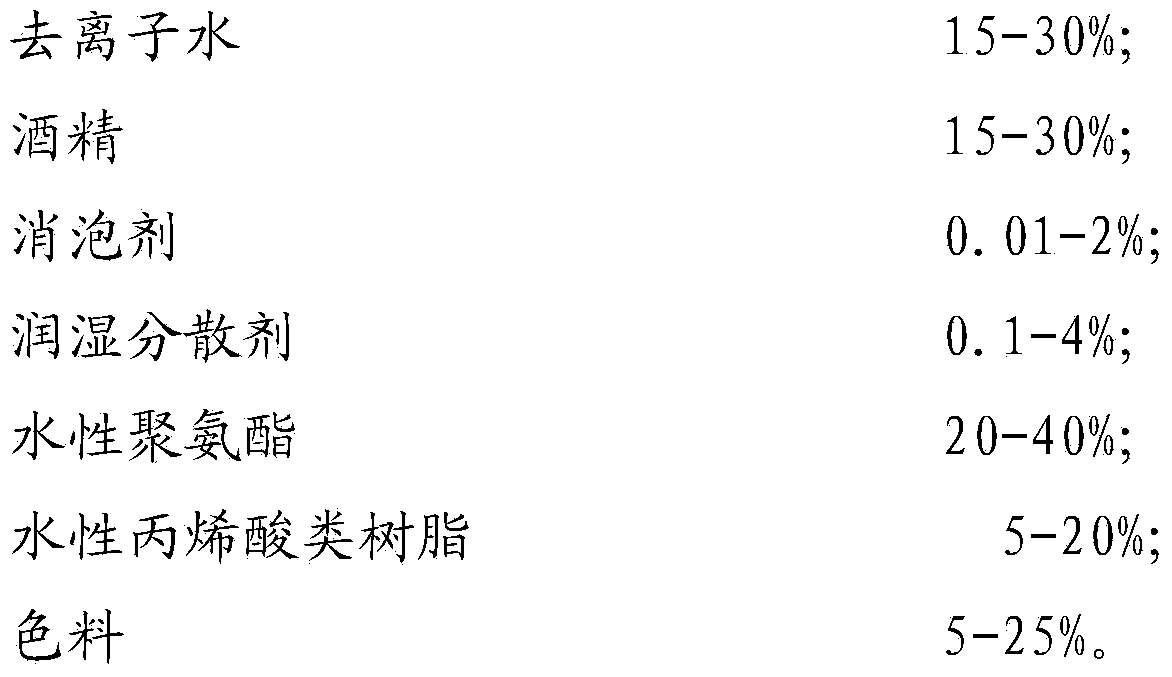

[0036]

[0037] The preparation method is:

[0038] First add deionized water and alcohol into the reaction vessel, start the disperser and mix thoroughly at 500-600r / min, then add defoamer, wetting and dispersing agent, and colorant. After dispersing at 600-1000r / min for 40 minutes, slowly add other materials while stirring according to the discharge order, and after dispersing for 50 minutes, filter and pack with 200-mesh filter cloth for use. The water-based laser anti-counterfeiting transparent ink is obtained.

Embodiment 3

[0040]

[0041] The preparation method is:

[0042] First add deionized water and alcohol into the reaction vessel, start the disperser and mix thoroughly at 500-600r / min, then add defoamer, wetting and dispersing agent, and pigment. After dispersing at 600-1000r / min for 40min, put the dispersed material into a horizontal sand mill and grind it two times and three times until the fineness is less than 10 microns and discharge the material. , slowly add other materials while stirring according to the discharge sequence, after dispersing for 50 minutes, filter and pack with 200-mesh filter cloth for use. The water-based laser anti-counterfeiting opaque ink is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com