A kind of production method of annealing and pickling of 409l cold-rolled steel strip

A technology of cold-rolled strip steel and pickling, which is applied in the direction of furnace types, furnaces, heat treatment furnaces, etc., can solve the problems of increasing production costs, and achieve the effects of saving investment, reducing production costs, and reducing the formation of oxide scales

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

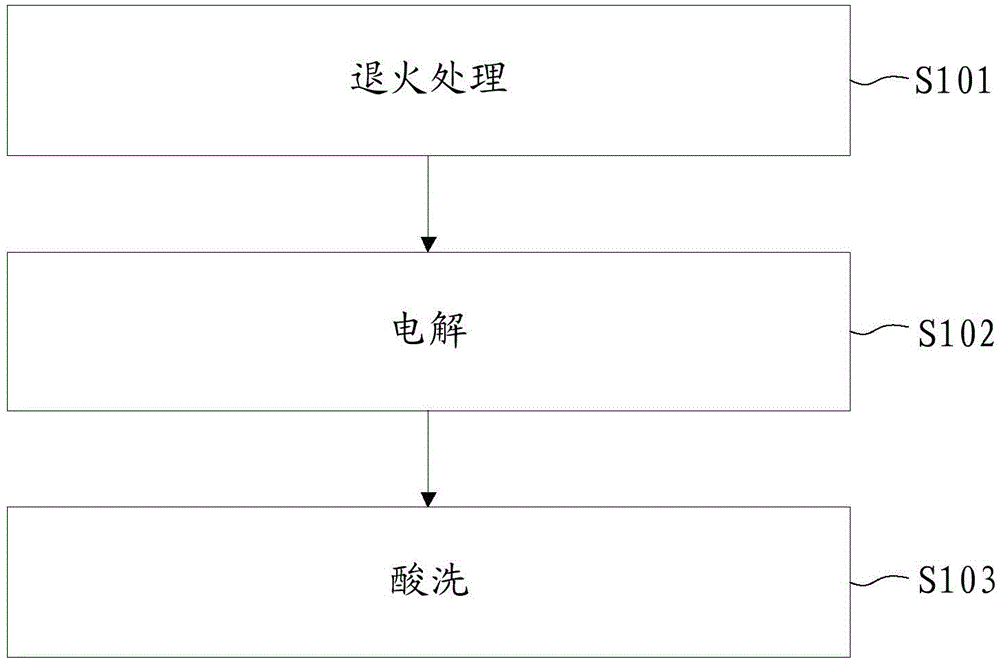

Image

Examples

Embodiment 1

[0028] The annealing and pickling production method of 409L cold rolled strip steel provided in this embodiment is as follows:

[0029] A1. Send the strip steel to the annealing furnace for annealing treatment. The temperature control of the annealing furnace includes two periods. In the first period, the temperature of the strip at the exit of the annealing furnace is 660°C and the excess oxygen concentration is 5.5%; in the second period, The strip temperature at the exit of the annealing furnace is 950℃, the excess oxygen concentration is 7.5%, and the strip annealing time is 21s;

[0030] A2. Send the annealed strip steel into a neutral salt solution for electrolysis, where the concentration of the neutral salt solution is 180g / L, the metal ion concentration is 6g / L, the temperature is 85℃, and the current density is 19A / dm 3 ; The electrolysis time is 33s;

[0031] A3. Carry out mixed acid pickling of strip steel after electrolysis treatment. The concentration of nitric acid in ...

Embodiment 2

[0033] The annealing and pickling production method of 409L cold rolled strip steel provided in this embodiment is as follows:

[0034] B1. Send the strip steel to the annealing furnace for annealing treatment. The temperature control of the annealing furnace includes two periods. In the first period, the temperature of the strip at the exit of the annealing furnace is 680°C and the excess oxygen concentration is 6.5%; in the second period, The temperature of the strip at the exit of the annealing furnace is 970°C, the excess oxygen concentration is 8.5%, and the strip annealing time is 46.5s.

[0035] B2. Send the annealed steel strip into a neutral salt solution for electrolysis, where the concentration of the neutral salt solution is 220g / L, the metal ion concentration is 10g / L, the temperature is 90℃, and the current density is 21A / dm 3 ; The electrolysis time is 37s;

[0036] B3. Carry out mixed acid pickling for strip steel after electrolysis treatment. The concentration of nit...

Embodiment 3

[0038] The annealing and pickling production method of 409L cold rolled strip steel provided in this embodiment is as follows:

[0039] C1. The strip steel is sent to the annealing furnace for annealing treatment. The temperature control of the annealing furnace includes two periods. In the first period, the temperature of the strip at the exit of the annealing furnace is 670℃ and the excess oxygen concentration is 6%; in the second period, The strip temperature at the exit of the annealing furnace is 957℃, the excess oxygen concentration is 8%, and the strip annealing time is 35s;

[0040] C2. Send the annealed steel strip into a neutral salt solution for electrolysis, where the concentration of the neutral salt solution is 200g / L, the metal ion concentration is 8g / L, the temperature is 87℃, and the current density is 20A / dm 3 ; The electrolysis time is 35s;

[0041] C3. Carry out mixed acid pickling of strip steel after electrolysis treatment. The concentration of nitric acid in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com