Paper honeycomb composite wall board and installing method of paper honeycomb composite wall board

A technology of composite wall panels and installation methods, which is applied to walls, building components, coverings/linings, etc., can solve the problems of limited installation and use of thermal insulation and decorative honeycomb panels, troublesome installation of connecting machines for thermal insulation and decorative honeycomb panels, and achieve beautiful appearance , Simple and convenient construction, high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

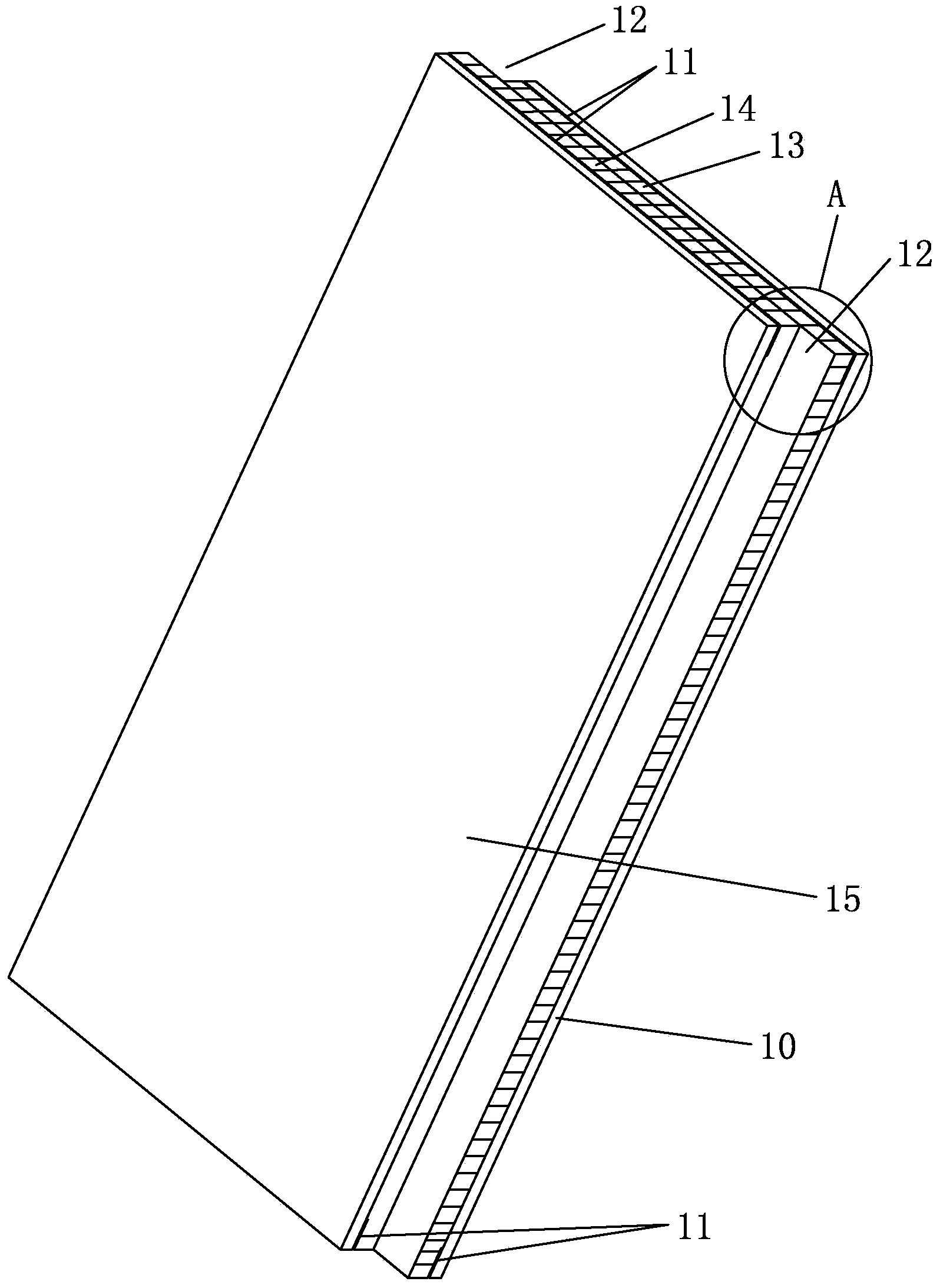

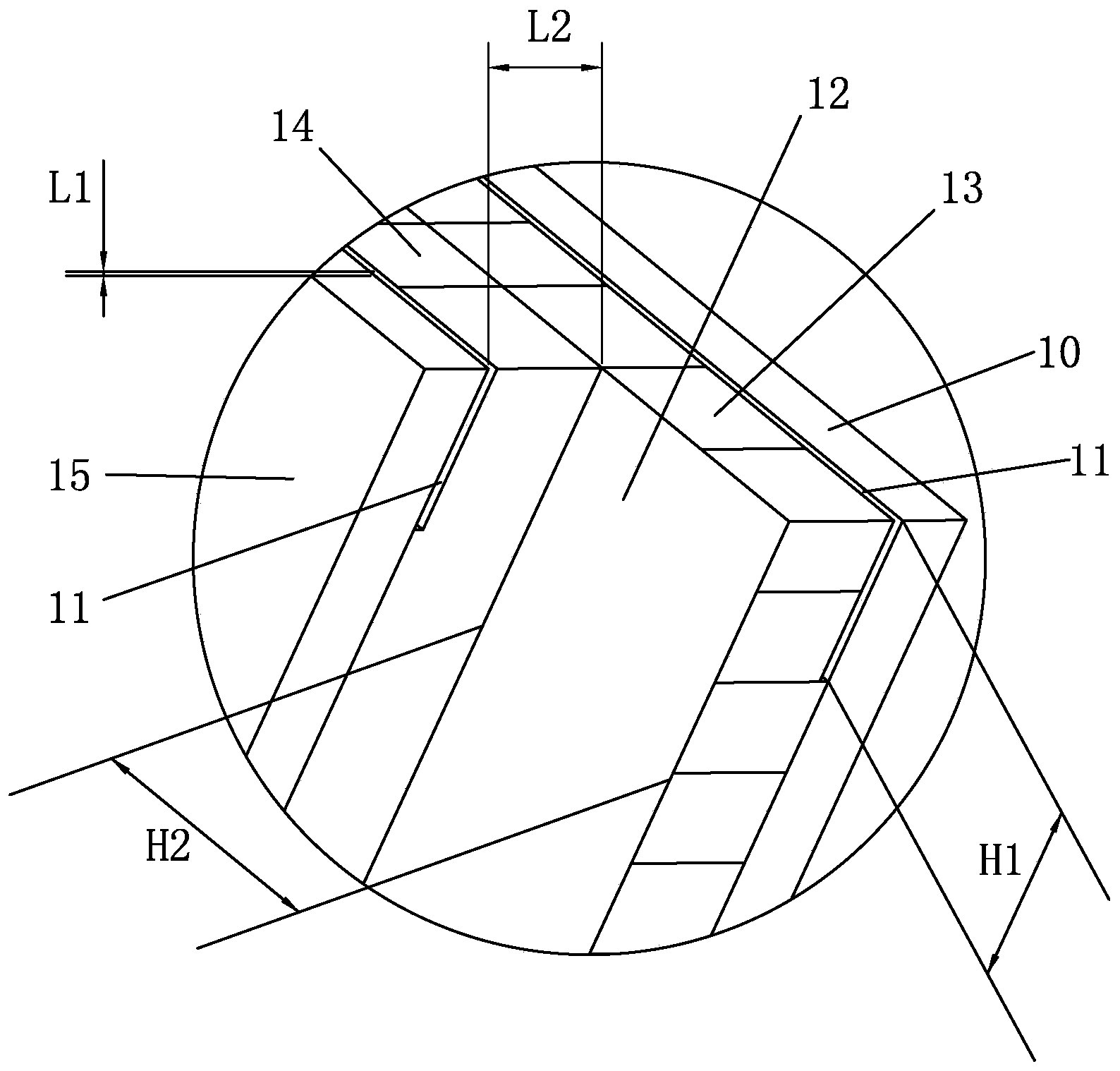

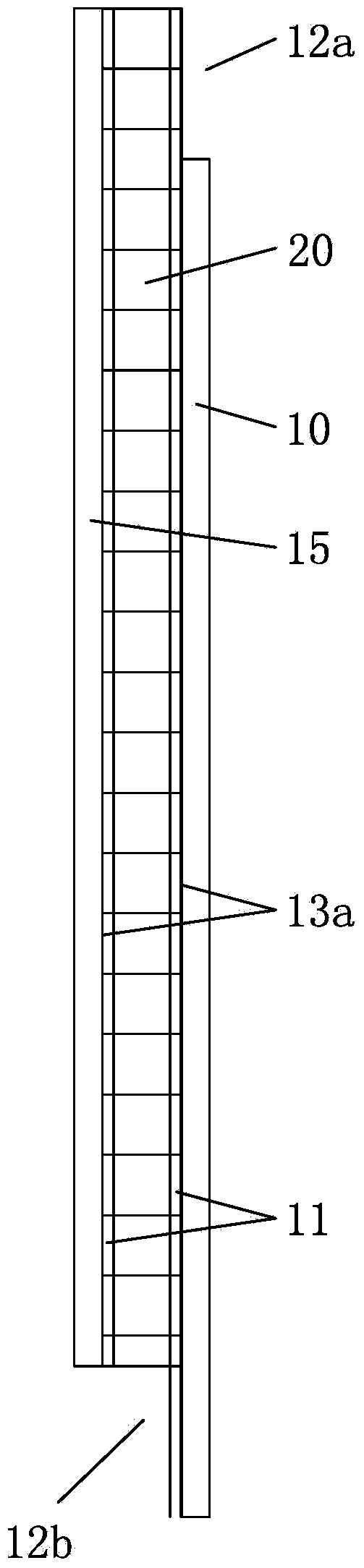

[0031] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 — Figure 8 :

[0032] A paper honeycomb composite wallboard, the upper and lower surfaces of a paper honeycomb core are respectively bonded with cardboard layers through an adhesive layer to form paper honeycomb panels 13, 14, and the upper and lower surfaces of the paper honeycomb panels 13, 14 are respectively bonded with adhesive layers Exterior panels 10, 15, the axes of the honeycomb holes of the paper honeycomb core are perpendicular to the planes where the exterior panels 10, 15 are located, and the exterior panels 10 on one side of the paper honeycomb panels 13, 14 are opposite to the paper Honeycomb panel 20 dislocation connections (see image 3 ) or from the central interface 14a of the paper honeycomb panels 13,14, the exterior panel 10 and the paper honeycomb panel 13 on one side are dislocated and connected with the exter...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap