Variable-vortex air inlet passage of multi-valve engine

A technology for air intakes and engines, which is applied in the direction of engine components, combustion engines, machines/engines, etc. It can solve the problems of reducing the flow cross-sectional area, insufficient intake air volume, and increasing the local resistance loss of intake air, so as to reduce the pumping loss , The effect of small airway flow capacity and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

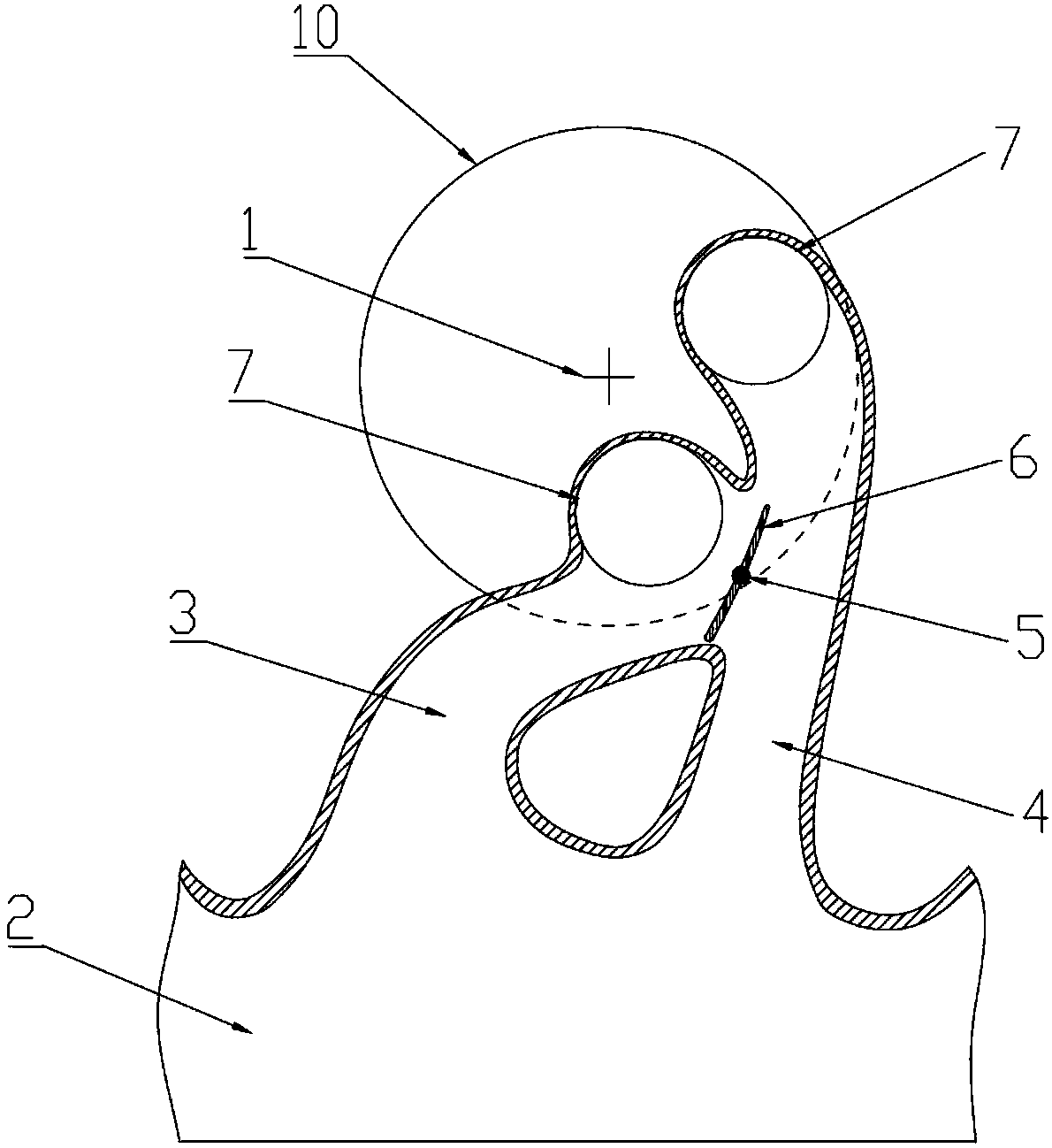

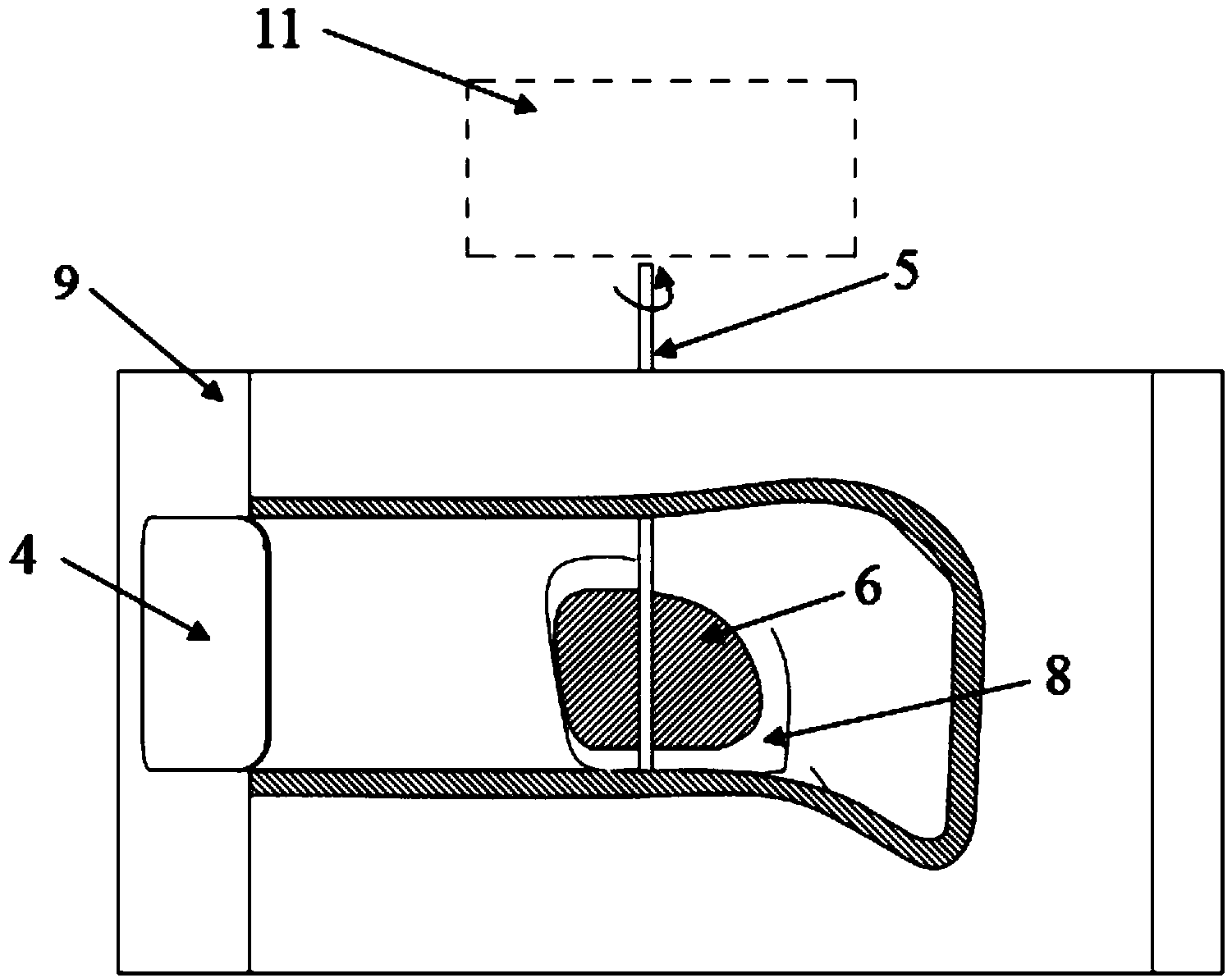

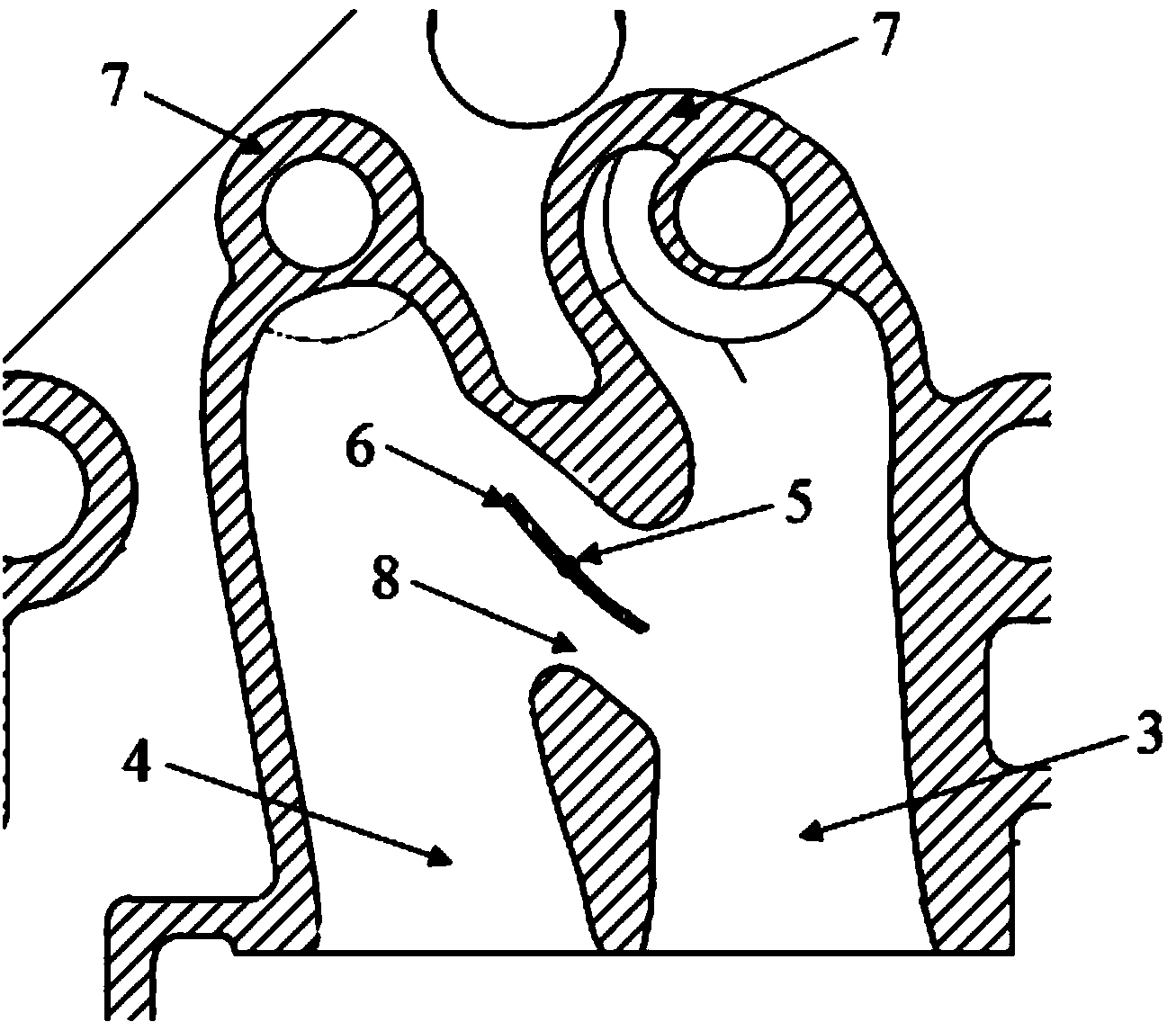

[0019] Such as figure 1 , 2 A variable swirl intake port for a multi-valve engine is shown, including an intake manifold 2, a first intake port 3, a second intake port 4, an intake adjustment channel 8, a swirl adjustment valve 6 and a swirl adjustment valve shaft 5 composition. The intake manifold 2 is connected with the first intake port 3 and the second intake port 4; the first intake port 3 and the second intake port 4 are communicated through an intake regulating channel 8; the intake air A vortex regulating valve 6 is installed in the regulating channel 8 ; the vortex regulating valve 6 rotates around the vortex regulating valve shaft 5 .

[0020] The first air inlet 3 is a spiral air passage, and the second air inlet 4 is a tangential air passage.

[0021] The first intake passage 3 and the second intake passage 4 communicate through an intake adjustment passage 8 ; the intake adjustment passage 8 is located in the middle and downstream of the first intake passage 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com