Automatic potentiometric titration method for determining acid value of tobacco essence and flavor before and after blending

A potentiometric titration method and a technology for tobacco flavors, which are applied in the quality control of primary and secondary blending tobacco flavors, and in the field of tobacco flavors before blending, can solve the problems of low detection accuracy, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

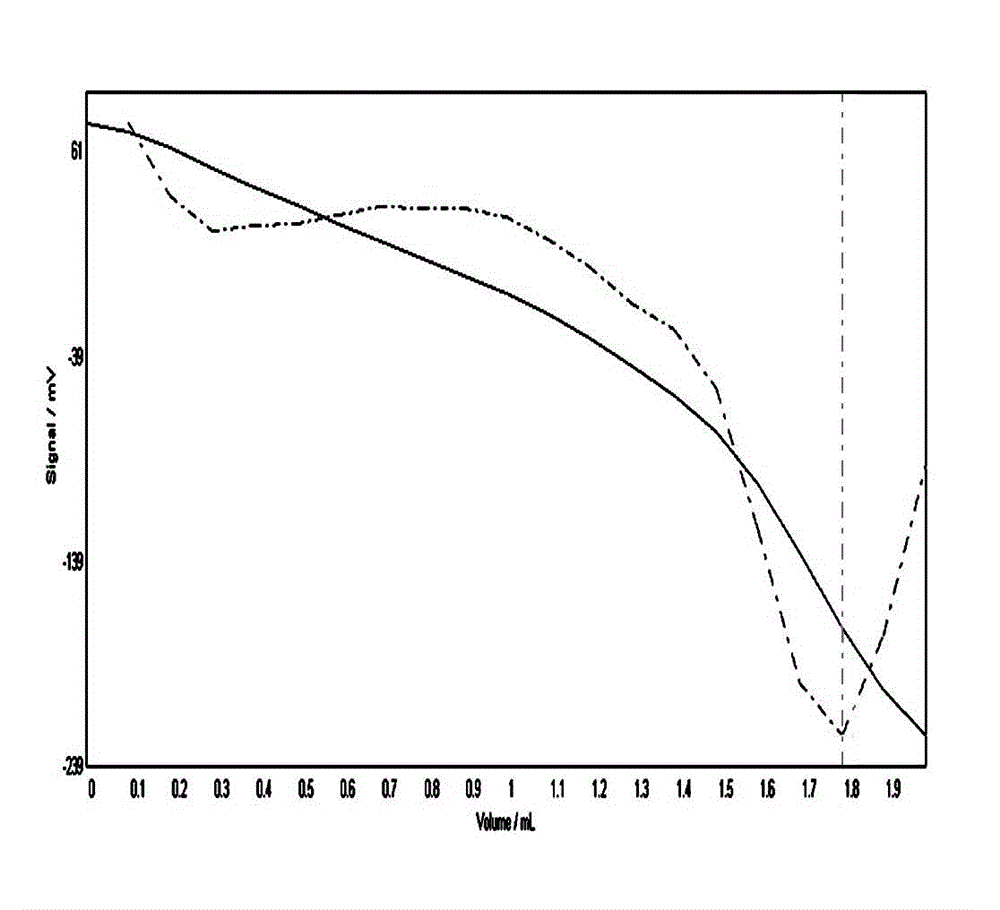

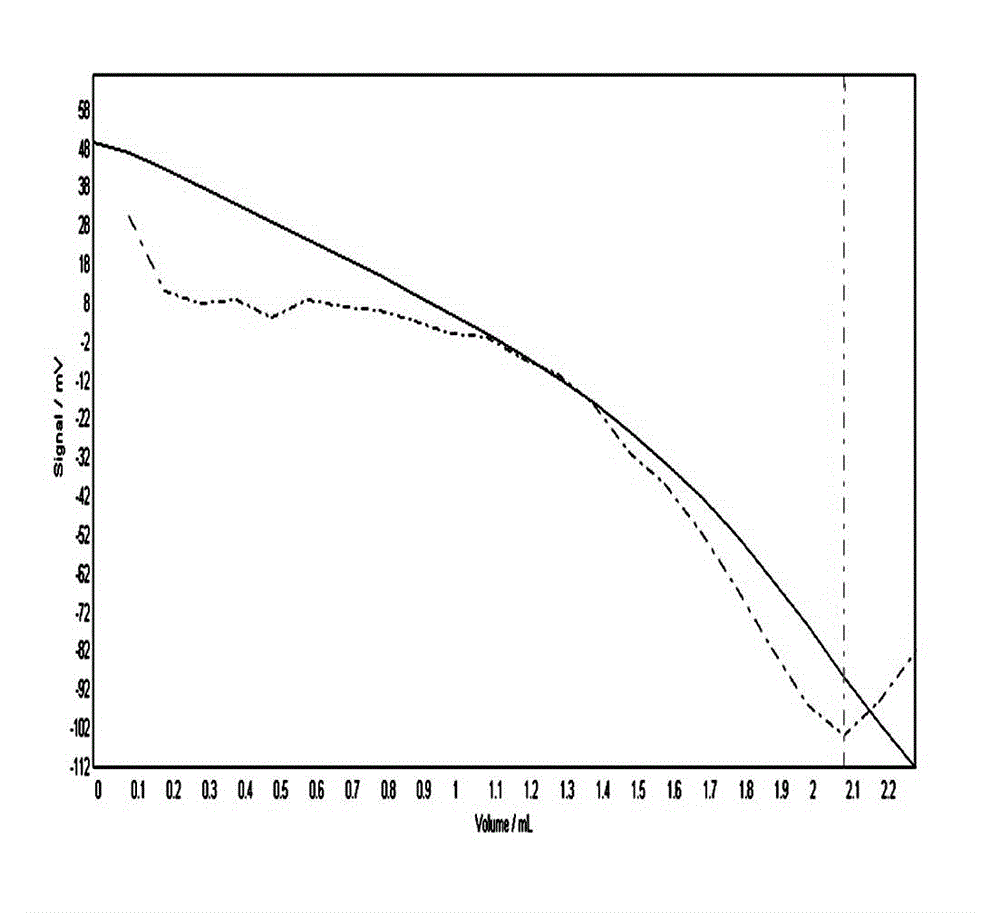

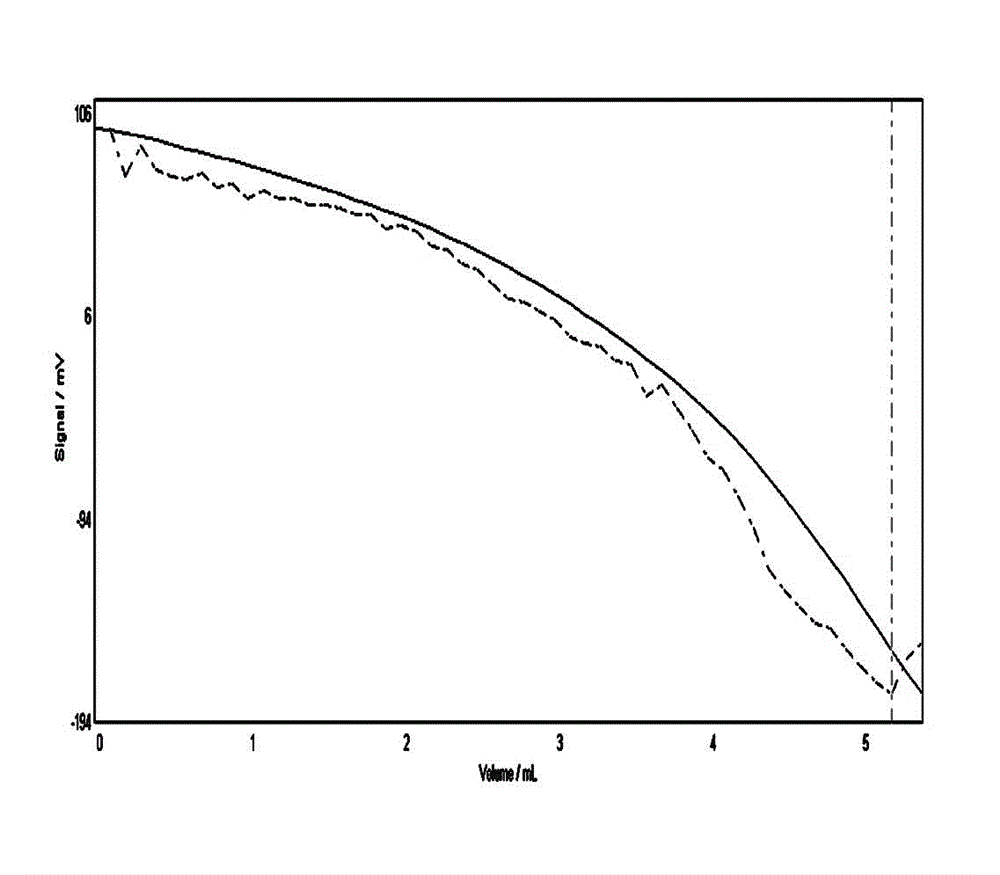

Image

Examples

Embodiment Construction

[0017] 1. Titrant preparation.

[0018] According to the steps of GB / T 601-2002 "Preparation of Chemical Reagent Standard Titration Solutions", weigh 0.7-1.0 g of analytically pure KOH, add 0.5 mL of ultra-pure water to dissolve, dilute to 1 L with 95% ethanol, and seal it for 24 hours , Transfer the supernatant to another polyethylene bottle to obtain a potassium hydroxide-ethanol solution with a concentration of 0.01mol / L. The exact concentration of potassium hydroxide-ethanol solution was calibrated before each experiment.

[0019] 2. Calibration of titrant.

[0020] 2.1. Pipette 3 parts of the same volume of 65-75% ethanol (V / V), titrate to the equivalence point, obtain the volume of titrant consumed and calculate the average value And store it as an auxiliary value H2, so that it can be called at any time in subsequent calculations.

[0021] 2.2. Accurately weigh 3 parts of 0.01g potassium hydrogen phthalate reference material dried at 105°C for 2 hours, add 1mL of ul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com