Low-cost refracting-reflecting athermalizing medium wave infrared lens

An infrared lens and catadioptric technology, applied in mirrors, optics, instruments, etc., can solve the problems of processing, detection and assembly difficulties, difficulty in cost control, and few aspheric mirrors, so as to achieve detection and assembly cost control and reduce convergence Angle, effect of processing cost control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to further clearly illustrate the present invention, specific embodiments will be provided below and combined with the accompanying drawings to describe the technical solution, but they should not be construed as limiting the present invention.

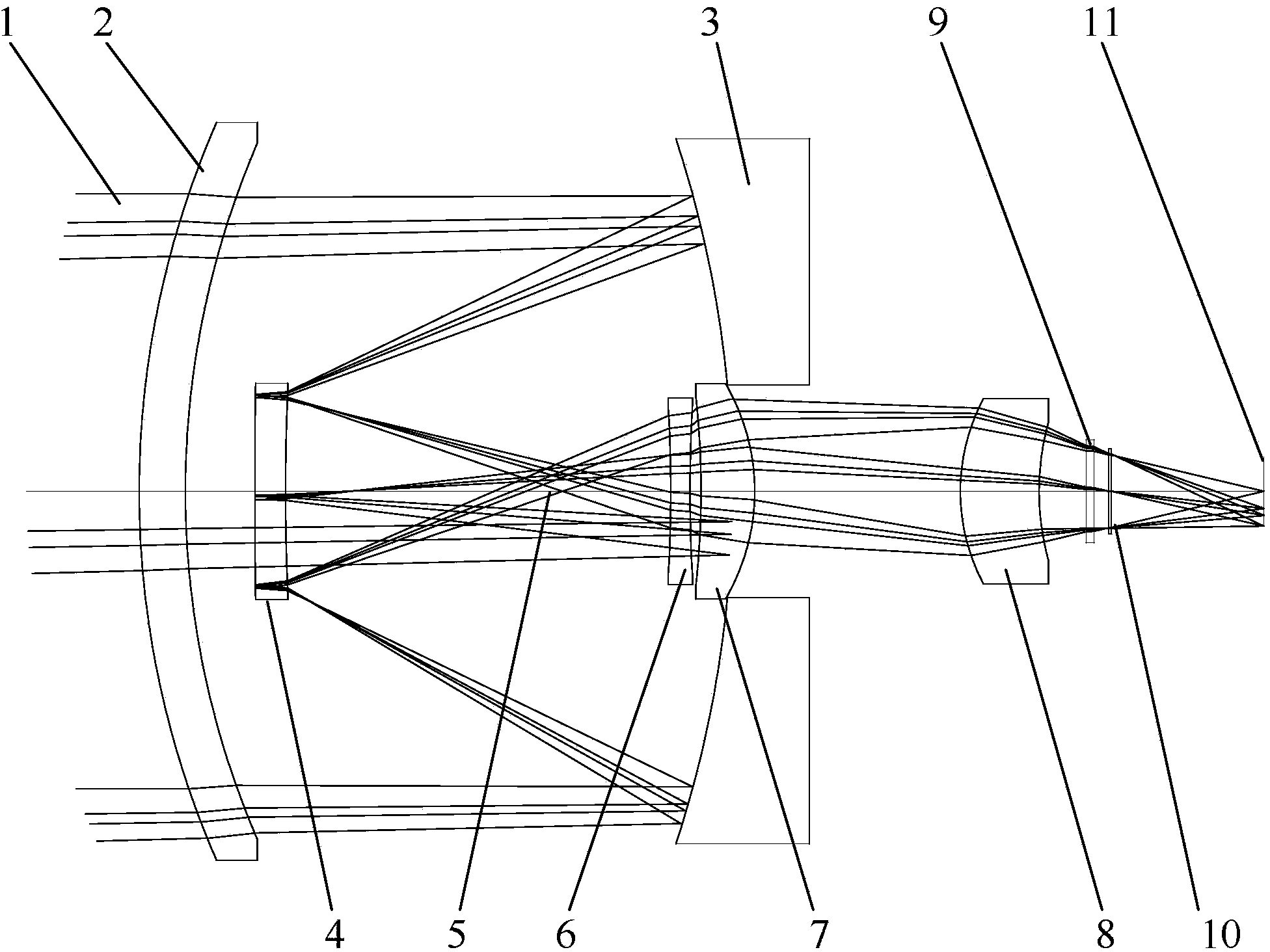

[0017] figure 1 The described low-cost catadioptric athermal difference mid-wave infrared lens mainly includes: an optical assembly from an infinite object plane 1 to a detector focal plane 11 . Wherein, the incident parallel light at infinity passes through the dome cover 2 and forms a converging light on the spherical main reflector 3 . The main reflecting spherical mirror 3 is spherical and made of aluminum alloy, and the mirror frame between the spherical main reflecting mirror 3 and the Mankin folding mirror 4 is made of aluminum alloy. The focal length of the spherical primary reflector 3 is about 86.07 mm at a detection wavelength of 4 μm.

[0018] The converging light formed by the spherical main reflector 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com