Automatic vibration calibration system and calibration method

A technology of calibration system and vibration table, applied in general control system, control/adjustment system, adaptive control and other directions, can solve the problems of easy to produce dead zone, unable to control vibration level, easy to make mistakes, etc., to improve labor efficiency and labor efficiency. The amount of tasks, the control system is more stable and more reliable, and the effect of reducing the error rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

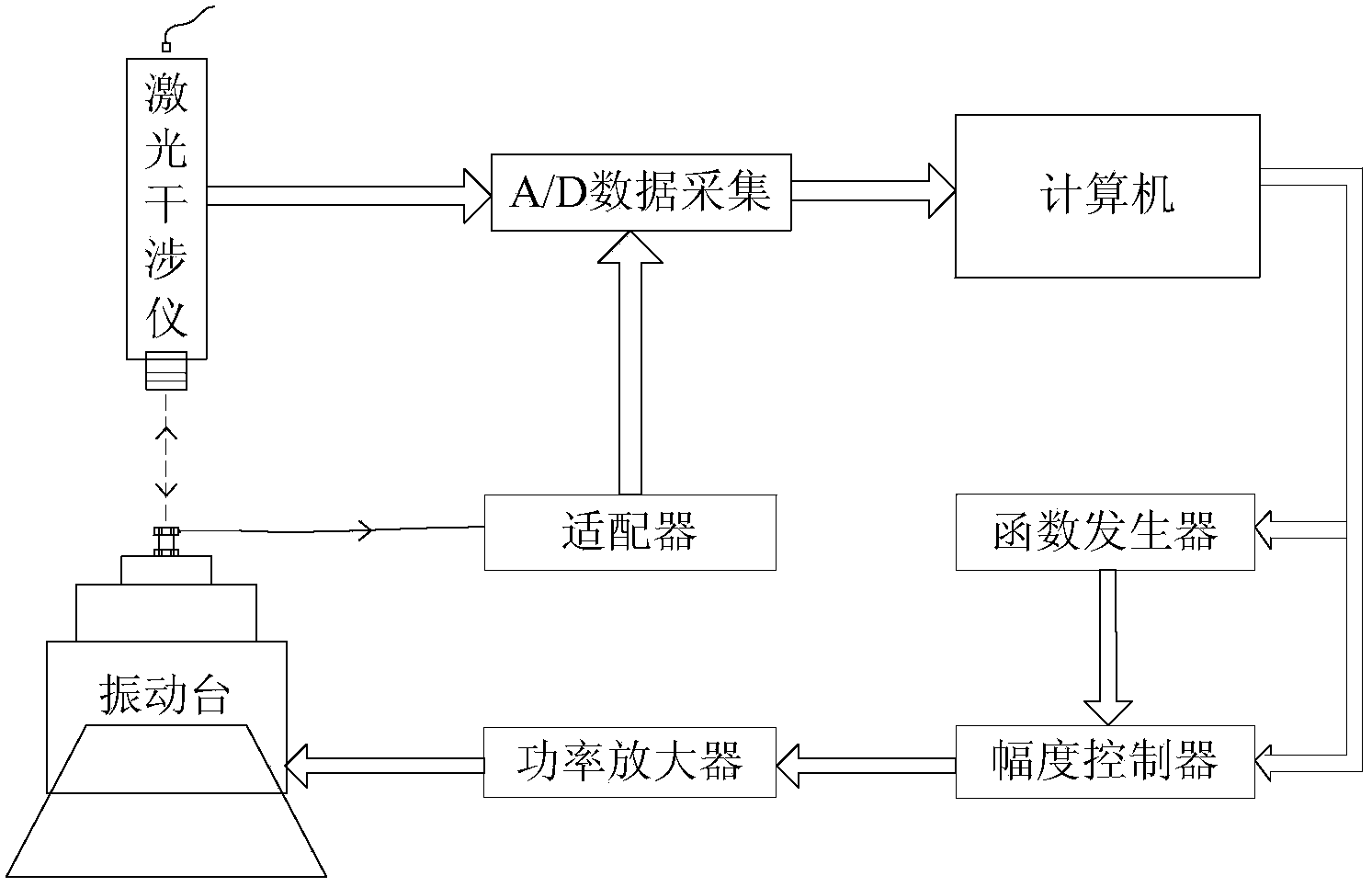

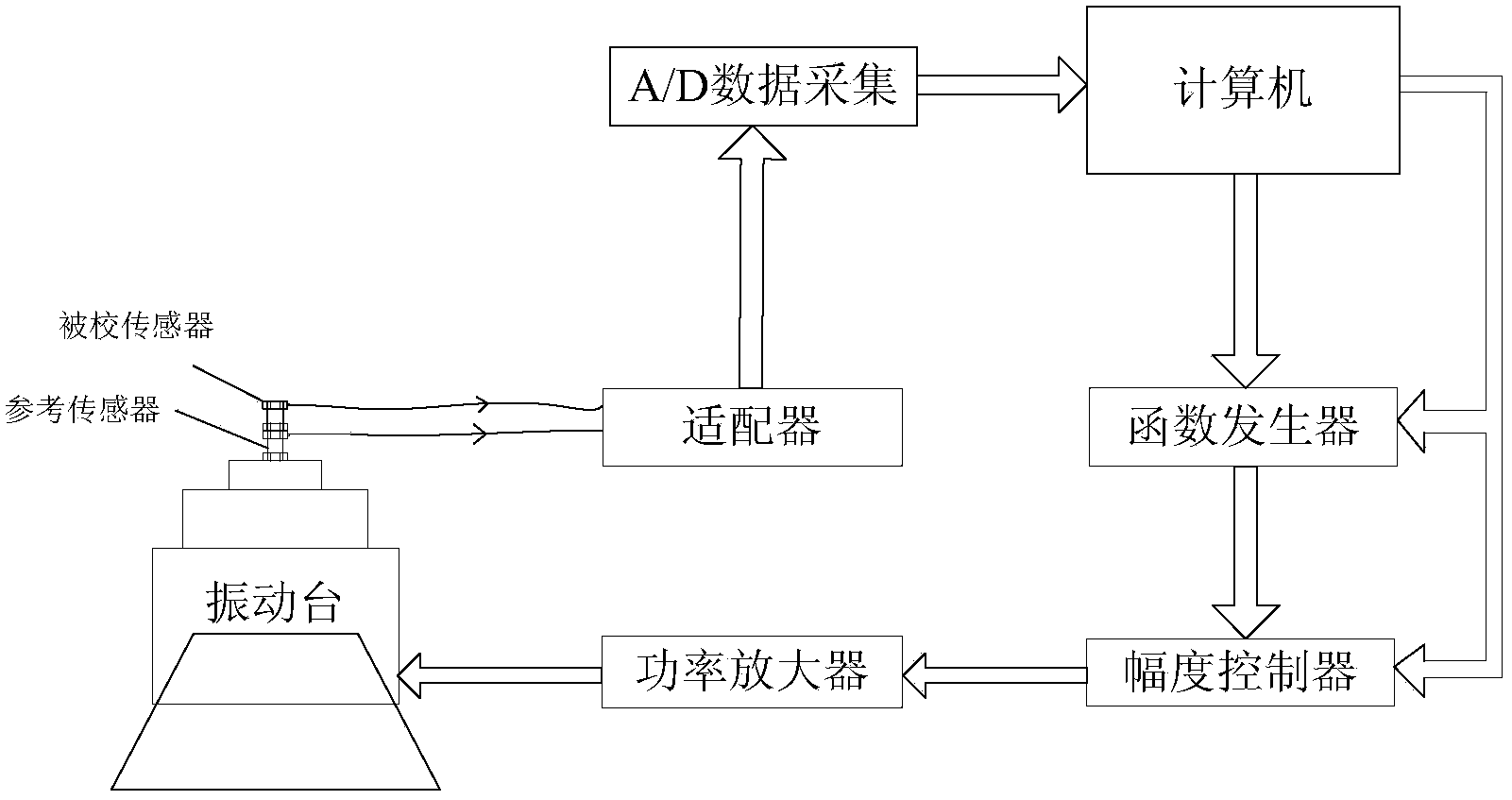

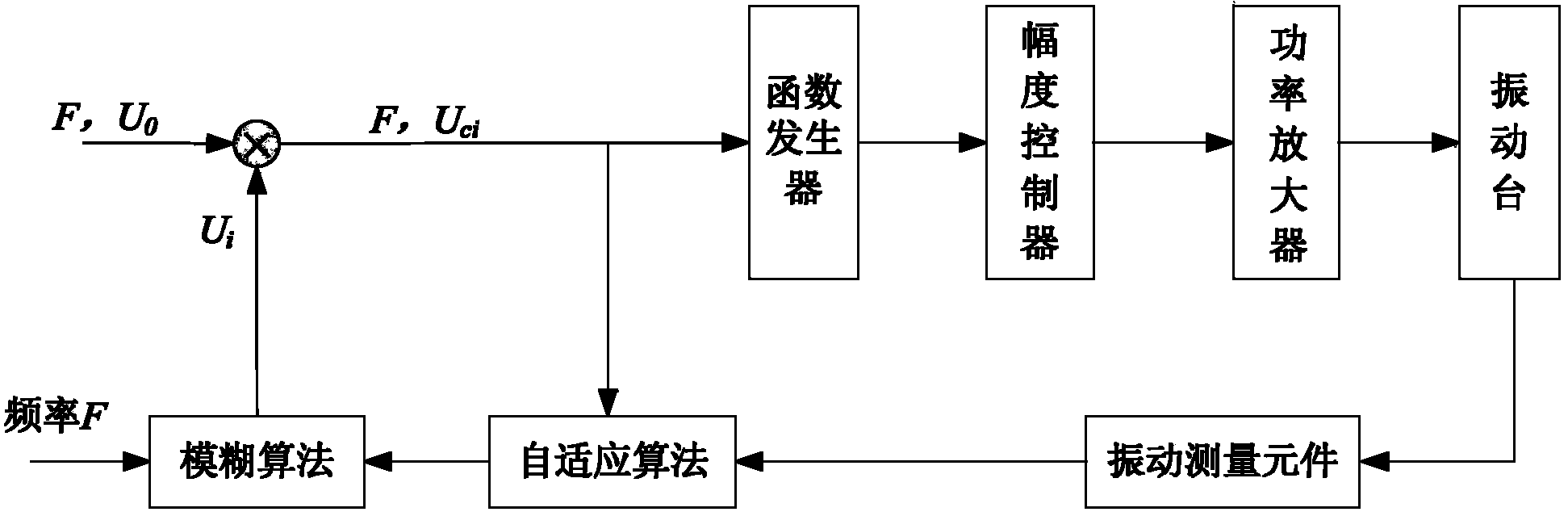

[0036] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0037] At present, with the rapid development of social science and technology, vibration sensors and vibration measuring instruments have been widely used in many fields. In order to ensure the reliability of the value of vibration sensors and vibration measuring instruments, it is necessary to perform vibration measurement calibration on them. In this case, the measurement and calibration department The workload of the verification personnel has gradually become heavier, and the error rate has gradually increased. Using this system can directly realize automatic vibration measurement calibration. On the premise of ensuring the high precision of measurement calibration, the workload of the tester is greatly reduced and the labor efficiency is improved. Moreover, the calibration of this system is rich in content, powerful in function, and easy to operate, covering acce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com