Weld joint excess weld metal processing device and weld joint processing method

A processing device and welding seam reinforcement technology, which is applied in the field of welding seam reinforcement processing devices, can solve the problems that the ultra-long welding seam reinforcement cannot be processed automatically, the quality of grinding and polishing is unstable, and the work efficiency is low, so as to achieve a compact structure , continuous milling, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

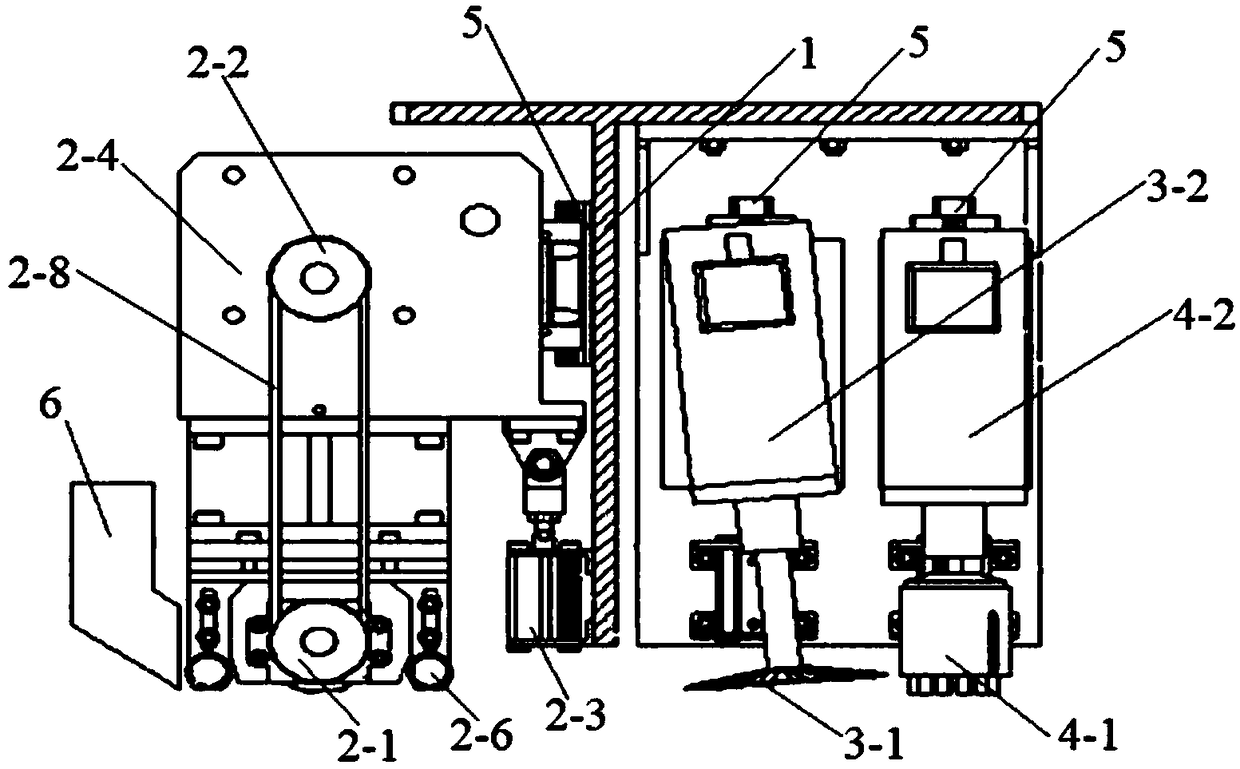

[0040] Such as Figure 1 to Figure 3 As shown, the embodiment of the present invention provides a welding seam reinforcement processing device, which includes a base frame 1, a milling unit, a polishing unit, and a grinding unit arranged between the milling unit and the polishing unit;

[0041] The milling unit comprises a milling cutter 2-1, a milling buffer floating part 2-3, a milling cutter fixed plate 2-4 and a milling driving part 2-2 arranged on the milling cutter fixing plate 2-4; the milling driving part 2-2 and The milling cutter 2-1 is connected to drive the milling cutter 2-1 to rotate; one end of the milling buffer floating part 2-3 is connected to the milling cutter fixed plate 2-4, and the other end is connected to the base frame 1, and the milling buffer floating part 2- 3 is used to drive the milling cutter fixing plate 2-4 to move up and down according to the residual height of the weld to be milled;

[0042] The grinding unit includes a louver wheel 3-1, a ...

Embodiment 2

[0055] The present invention also provides a welding seam processing method based on the above-mentioned welding seam reinforcement processing device, the method includes the following steps:

[0056] Install the base frame 1 on the moving mechanism of the automation equipment, and make the milling cutter 2-1 close to the starting end of the weld seam to be milled

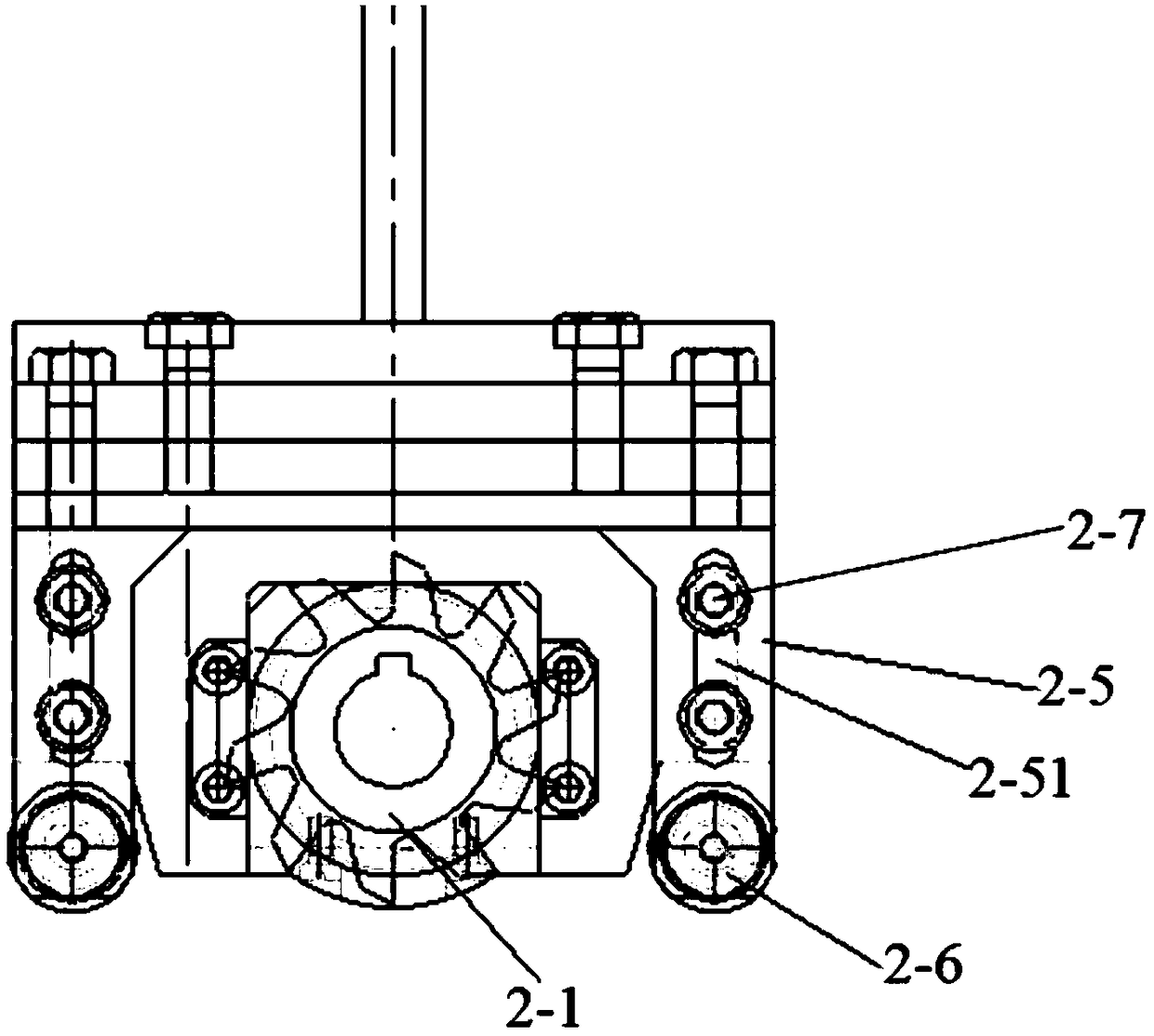

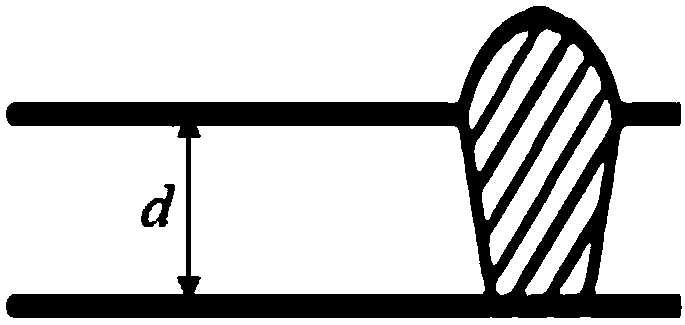

[0057] Adjust the height of the guide adjustment plate 2-5 relative to the milling cutter 2-1, specifically: when the preset weld residual height is high, first loosen the bolt 2-7, and then move the guide adjustment plate 2-5 upwards Tighten the bolt 2-7 until the distance between the limit roller 2-6 and the milling cutter 2-1 is equal to the preset weld residual height. Conversely, when the preset welding seam residual height is low, after loosening the bolt 2-7, move the guide adjustment plate 2-5 downward until the gap between the limit roller 2-6 and the milling cutter 2-1 Tighten the bolts 2-7 after the dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com