A small shrinking machine control system and method thereof

A technology of control system and shrinking machine, applied in the direction of digital control, electrical program control, etc., can solve the problems of low degree of automation, poor quality of finished products, high failure rate, etc., achieve high precision, prevent the reduction of cloth quality, and have good coordination Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

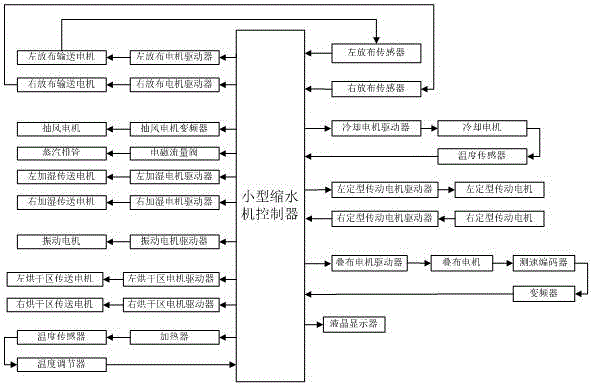

[0020] Such as figure 1 As shown, the control system of the small shrinking machine includes the left cloth feeding motor driver, the left cloth feeding motor, the right cloth feeding motor driver, the right cloth feeding motor, the fan inverter, the fan motor, the electromagnetic flow valve, the steam pipe, the left Humidification motor driver, left humidification transmission motor, right humidification motor driver, right humidification transmission motor, vibration motor driver, vibration motor, left drying zone motor driver, left drying zone transmission motor, right drying zone motor driver, right drying Area conveying motor, heater, temperature sensor, temperature regulator, left cloth feeding sensor, right cloth feeding sensor, cooling motor driver, cooling motor, temperature sensor, left shaping drive motor driver, left shaping driving motor, right shaping driving motor driver , right shaping drive motor, stacking motor driver, stacking motor, speed measuring encoder,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com