110 kv cable main insulation electric molding cutter

A 1.110kv, main insulation technology, applied in the direction of dismantling/armouring cable equipment, etc., can solve the problems of rough cutting and unevenness of cable heads, and achieve the effect of ensuring construction quality, easy maintenance, and easy parts replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

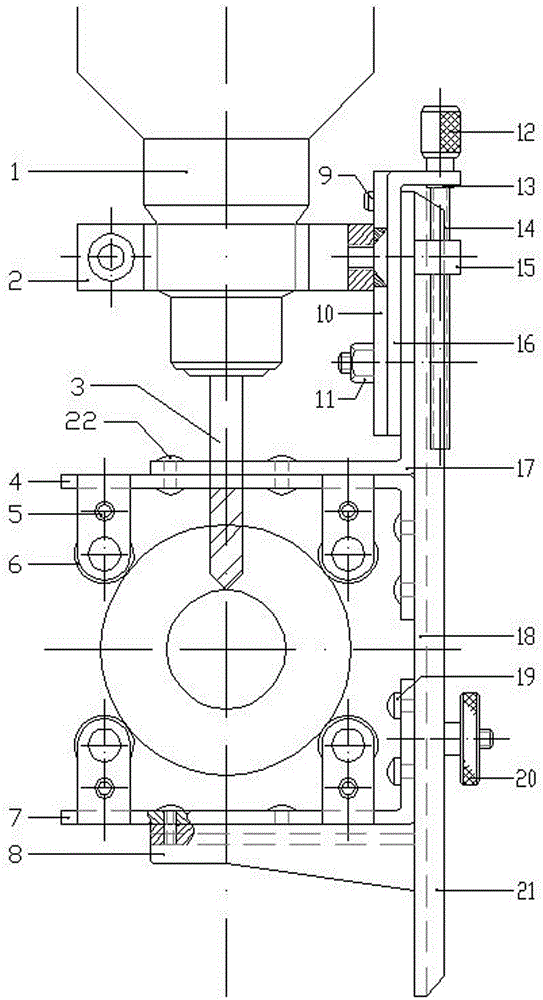

[0014] Such as figure 1 As shown, the 110kV cable main insulation electric forming cutter includes a power head 1, the power head 1 is equipped with a power head frame 2, and the power head frame 2 is equipped with a cutter 3 and an adjustment device for adjusting the position of the cutter. The adjustment device is fixed On the grooved back plate 21, the grooved back plate 21 at the lower part of the adjustment device is equipped with an upper guide wheel joint plate 4 and a lower guide wheel joint plate 7, and the upper guide wheel joint plate 4 and the lower guide wheel joint plate 7 are installed correspondingly. axle 6. The axles 6 of the upper guide wheel link plate 4 and the lower guide wheel link plate 7 are respectively divided into two groups, and the axle wheel brake button 5 is arranged on the wheel axle 6. axial movement.

[0015] The adjustment device includes an angle adjustment plate 10, the angle adjustment plate 10 is installed on the side of the power head...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com