Direct molding process for hot-extruded hollow axle

A hollow axle and forming process technology, which is applied in the field of metal forging and processing, can solve the problems of failing to fully utilize the use effect of the hollow axle, the processing quality cannot be guaranteed, and the production cost remains high, and is suitable for large-scale industrial production and upgrading. Use quality, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

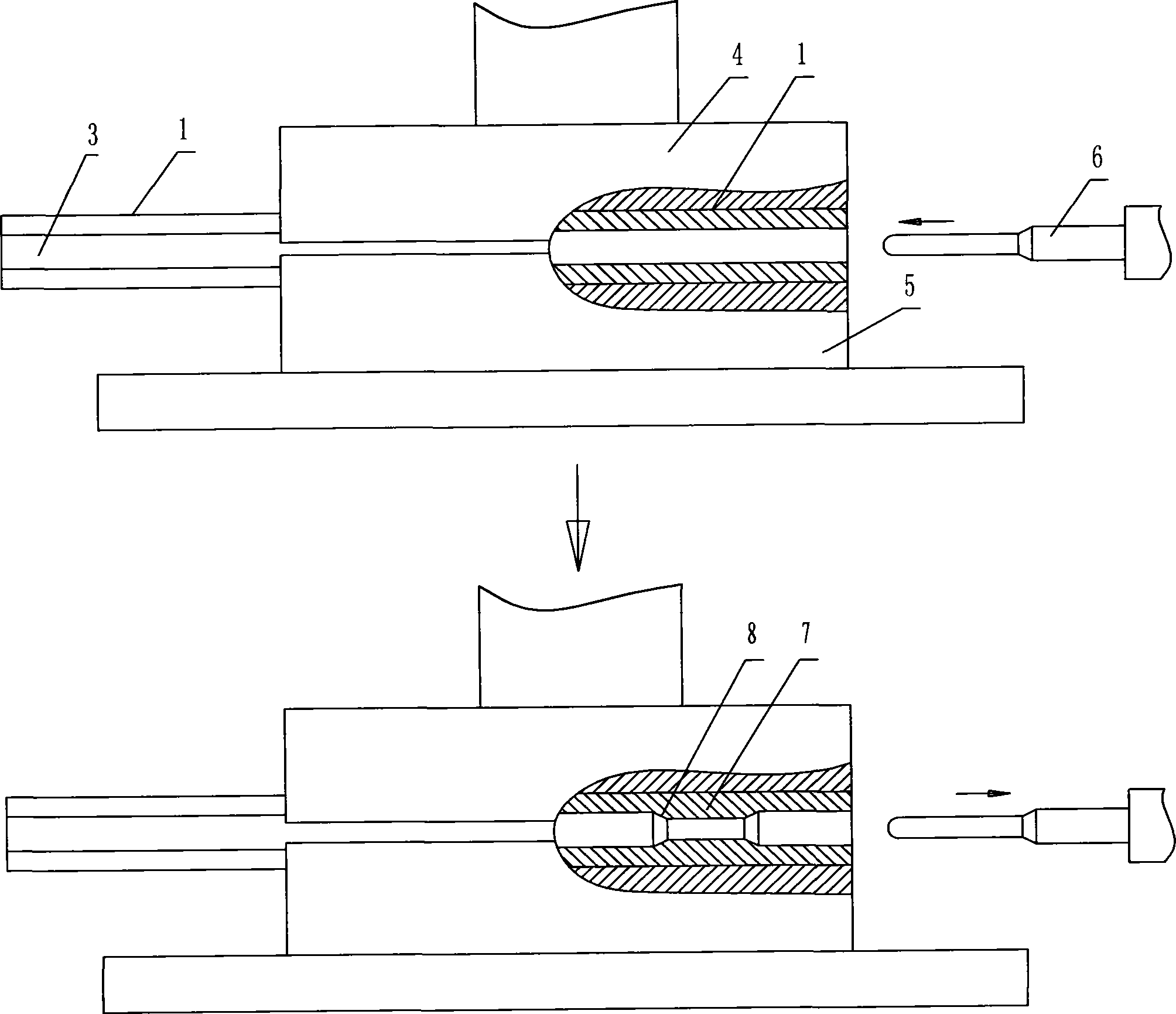

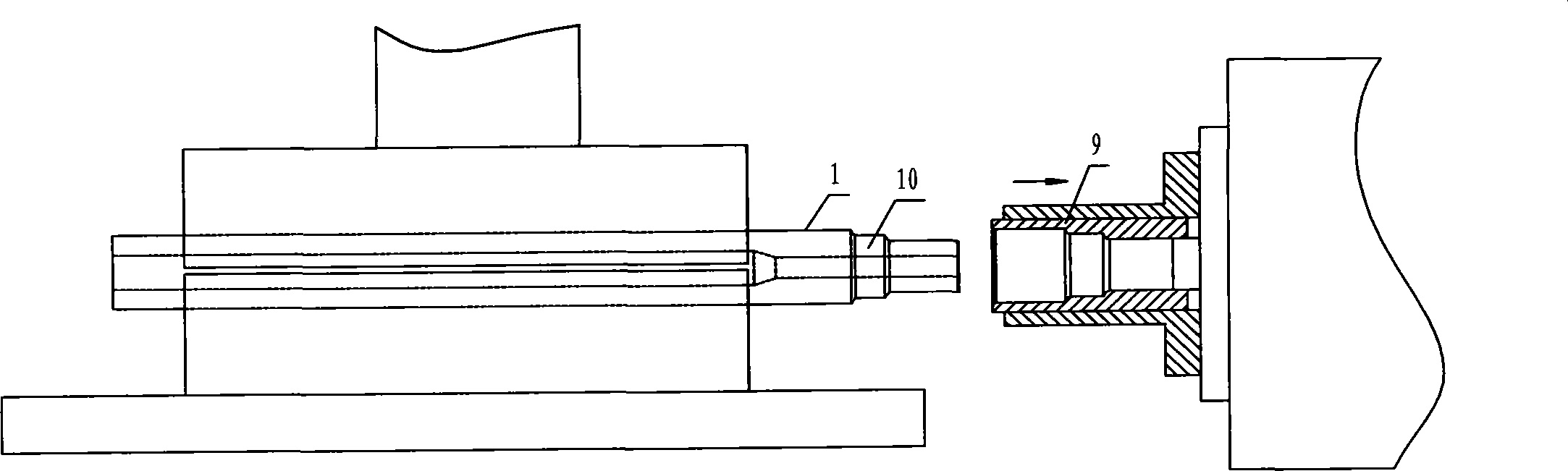

[0023] The purpose of the process of the present invention is: first retract the inside, upsetting the outer diameter of the wheel seat, and then add mandrels to close the bearing seat to complete the diameter reduction process of the hollow axle. The specific method is: use the heat treatment method of gradient heating, combined with the corresponding split mold, carry out hot extrusion under the action of horizontal and vertical loading forces, complete the direct variable diameter forming of the hollow axle under a fixed range and constant pressure, and then assist the external Round and inner hole processing to realize the integral molding of the hollow axle.

[0024] Take the hollow axle shaft of actual processing high-speed train as example below, in conjunction with accompanying drawing, the present invention is described further:

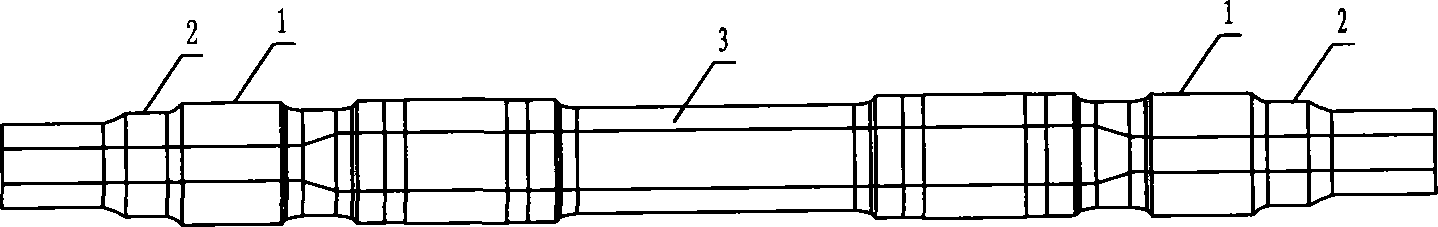

[0025] Such as figure 1 As shown, the two sides of the hollow axle 3 according to the present invention are the bearing seat position 2 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com