A method of preparing sulfur-doped graphene by chemical vapor deposition

A technology of sulfur-doped graphene and chemical vapor deposition, which is applied in the field of materials to achieve the effect of controllable doping and low economic cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

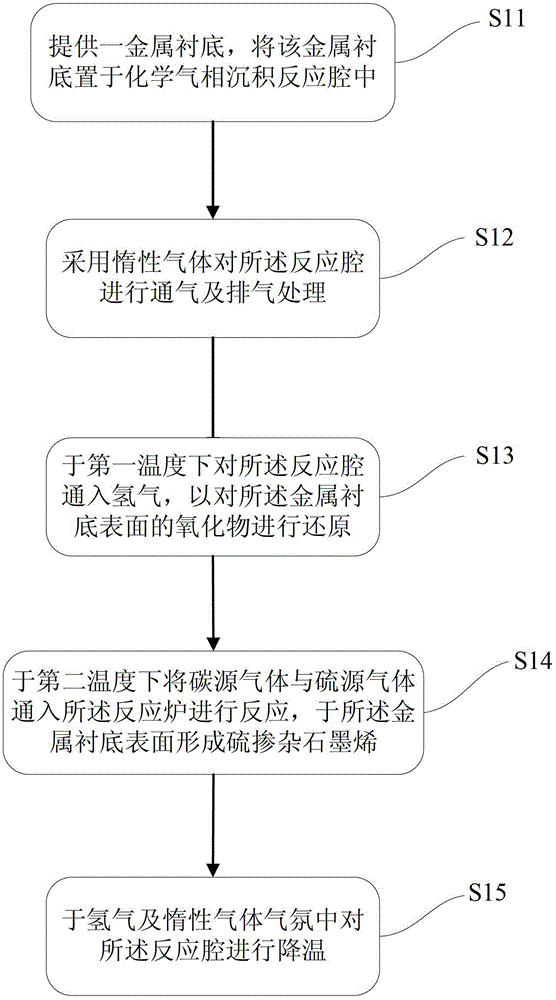

[0031] Such as Figure 1 ~ Figure 3 As shown, the present embodiment provides a method for preparing sulfur-doped graphene by chemical vapor deposition, at least including the following steps:

[0032] First, step 1) S11 is performed, providing a metal substrate, and placing the metal substrate in a chemical vapor deposition reaction chamber.

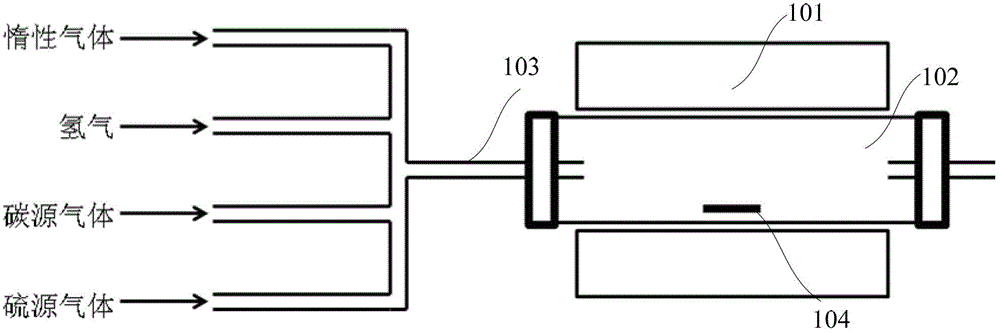

[0033] As an example, the structure of the chemical vapor deposition reaction chamber is as follows figure 1 As shown, it includes a tube furnace 101 , a quartz tube 102 and a gas passage 103 .

[0034] As an example, the metal substrate is copper foil, and the size of the copper foil is 2cm*2cm. Of course, the size of the copper foil can be changed according to actual requirements, so as to prepare sulfur-doped graphene of different sizes to meet different technological requirements.

[0035] Then proceed to step 2) S12, using an inert gas to ventilate and exhaust the reaction chamber.

[0036] As an example, the aeration and exhau...

Embodiment 2

[0048] Such as Figure 1 ~ Figure 3 As shown, the present embodiment provides a method for preparing sulfur-doped graphene by chemical vapor deposition, at least including the following steps:

[0049] First, step 1) S11 is performed, providing a metal substrate, and placing the metal substrate in a chemical vapor deposition reaction chamber.

[0050] As an example, the structure of the chemical vapor deposition reaction chamber is as follows figure 1 As shown, it includes a tube furnace 101 , a quartz tube 102 and a gas passage 103 .

[0051] As an example, the metal substrate is an electroplated copper layer with a thickness of 10 μm on the surface of a silicon wafer with an oxide layer. During the preparation process, the size of the electroplated copper can be changed according to actual requirements, so as to prepare sulfur-doped graphene of different sizes to meet different process requirements.

[0052] Then proceed to step 2) S12, using an inert gas to ventilate and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com