A method of sulfur-doping graphene

A technology of graphene and sulfur doping, applied in the field of materials, to achieve the effects of controllable doping, simple and efficient sulfur doping, and low economic cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

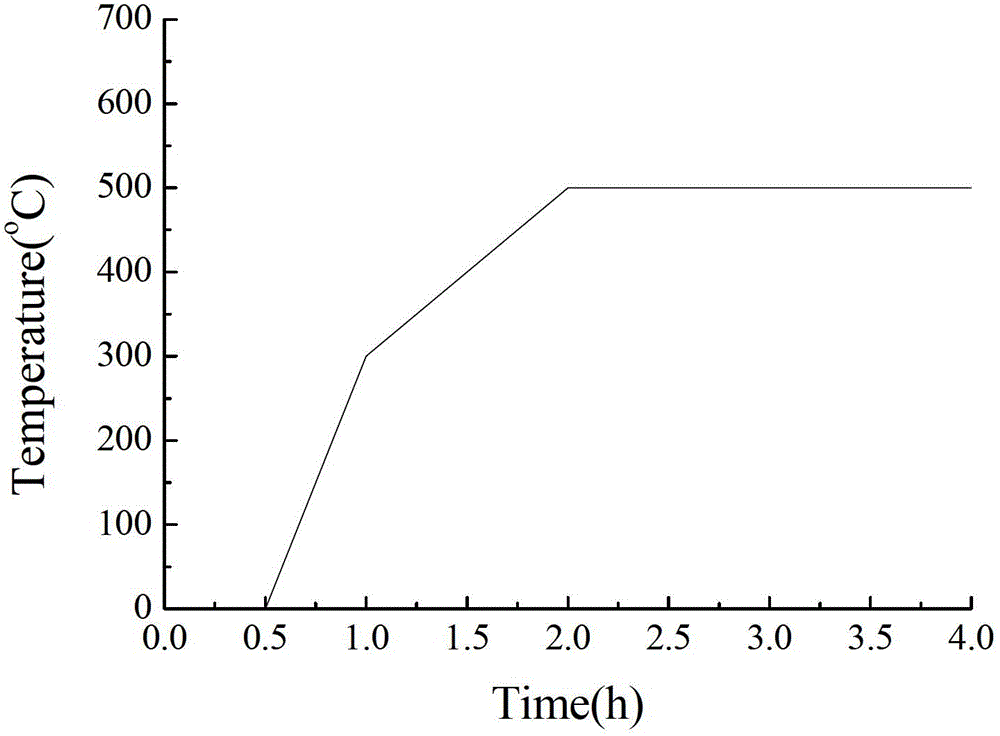

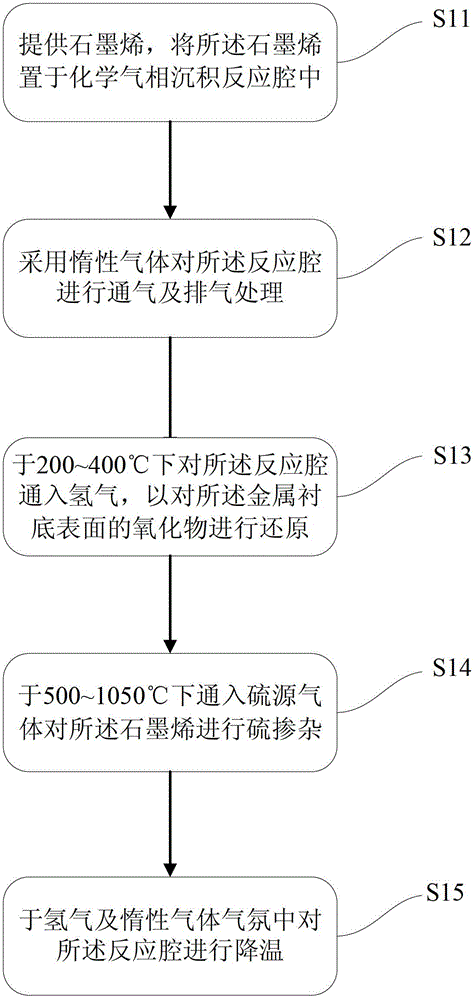

[0035] Such as Figure 1 ~ Figure 3 As shown, this embodiment provides a method for sulfur doping graphene, which at least includes the following steps:

[0036] First, perform step 1) S11, provide graphene, and place the graphene in a chemical vapor deposition reaction chamber;

[0037] Then proceed to step 2) S12, using inert gas to vent and exhaust the reaction chamber;

[0038] Then proceed to step 3) S14, passing a sulfur source gas at 500 to 1050°C to sulfur dope the graphene;

[0039] Finally, step 4) S15 is performed to cool the reaction chamber in a hydrogen and inert gas atmosphere.

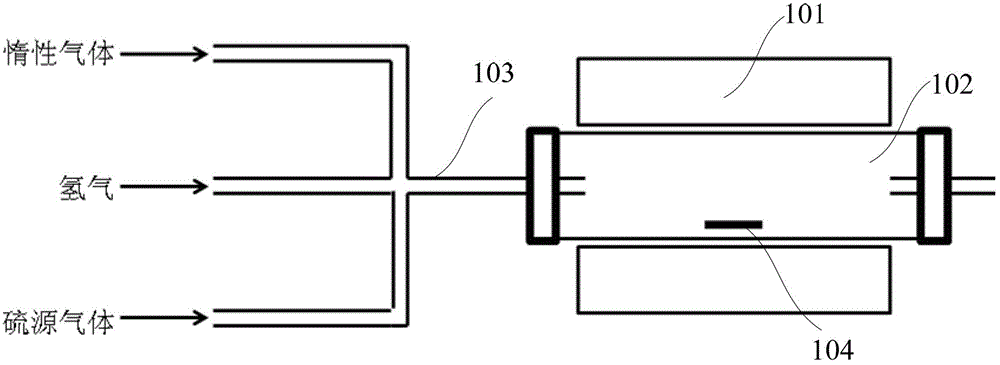

[0040] As an example, the structure of the chemical vapor deposition reaction chamber is figure 1 As shown, the tube furnace 101, the quartz tube 102, and the air passage 103 are included.

[0041] As an example, the graphene 104 is placed in the reaction chamber with a metal substrate as a carrier. After step 2), it further includes step a) S13, in which hydrogen gas is fed into the reaction cha...

Embodiment 2

[0049] Such as figure 1 and Figure 4 As shown, this embodiment provides a method for sulfur doping graphene, which at least includes the following steps:

[0050] First, perform step 1) S21, provide graphene, and place the graphene in a chemical vapor deposition reaction chamber;

[0051] Then proceed to step 2) S22, using inert gas to vent and exhaust the reaction chamber;

[0052] Then proceed to step 3) S23, introducing a sulfur source gas at 500-1050°C to dope the graphene with sulfur;

[0053] Finally, step 4) S24 is performed to cool the reaction chamber in a hydrogen and inert gas atmosphere.

[0054] As an example, the structure of the chemical vapor deposition reaction chamber is figure 1 As shown, the tube furnace 101, the quartz tube 102, and the air passage 103 are included.

[0055] As an example, in step 1), the graphene 104 is placed in the reaction chamber using a silicon substrate with an insulating layer as a carrier. The graphene on the insulating substrate is direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com