Transesterification preparation method for 1,3-dioleic acid-2-triglyceride palmitate

A technology of palmitic acid triglyceride and palmitic acid, which is applied in the field of oil processing, can solve the problems of unfavorable environmental protection, cumbersome, solvent waste process, etc., and achieve the effect of convenient local materials and simple reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1 Separation and purification of fatty acids

[0036] 1. Extraction of fatty acids in lard

[0037]取1g猪油、0.23g KOH、2.64mL95%乙醇及0.44mL水,在60℃下水浴反应1h,再加入蒸馏水、正己烷,萃取后得到水相。用盐酸调节pH至1.0,再用正己烷萃取,得到的油相经氮吹除去溶剂,得到混合脂肪酸。

[0038] 2.脂肪酸的分离

[0039] 取上述得到的混合脂肪酸,与丙酮按每克40mL的比例在40℃条件下搅拌直到所有的脂肪酸溶解。使该溶液冷却至室温,随后在-24℃储存24h。在-24℃条件下过滤,得到的固相饱和脂肪酸主要成分为棕榈酸,作为下一步合成的原料之一。将过滤得到的液相进行氮吹,得到不饱和脂肪酸主要为油酸和亚油酸,留待进一步纯化以得到较高含量的油酸。

[0040] 3.不饱和脂肪酸的纯化

[0041] 将上述方法中分离得到的液相不饱和脂肪酸以每克60mL的比例继续溶解于乙腈中,在-24℃储存24h。在-24℃条件下过滤后进行氮吹,继续提高油酸的含量比例。

Embodiment 2

[0042] 实施例2 棕榈酸甘油三酯(PPP)的合成

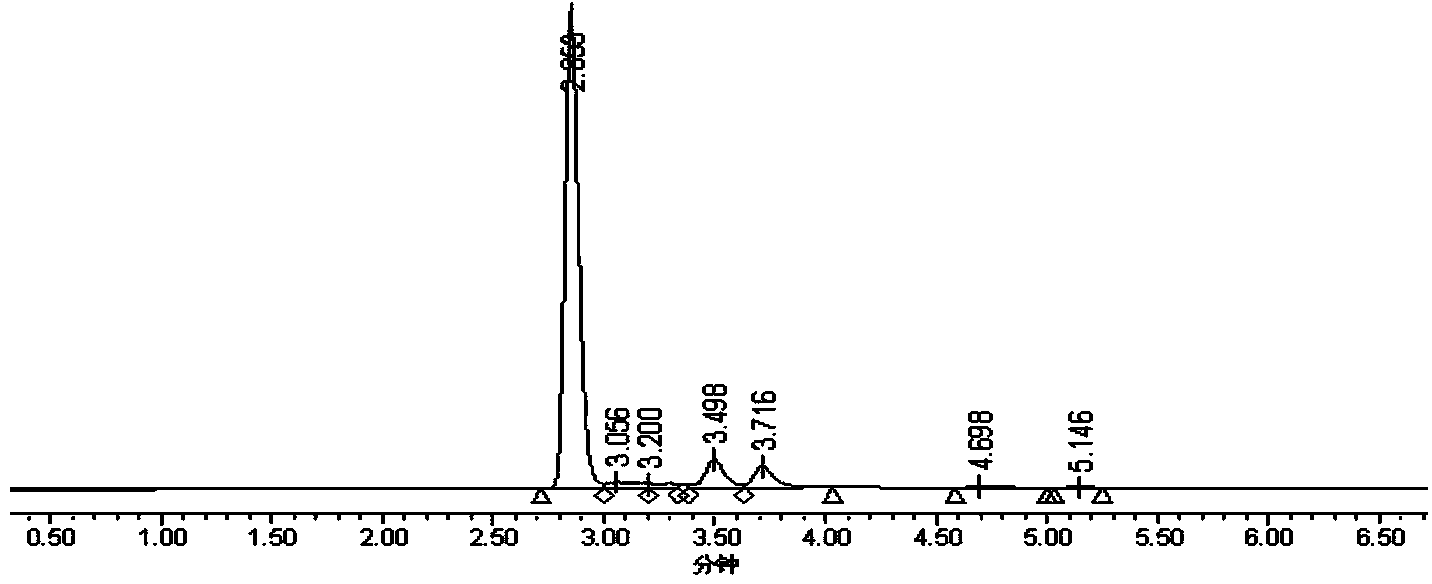

[0043] 选用褶皱假丝酵母脂肪酶(lipase from Candida rugosa)作为生物催化剂,催化实施例1中分离出的棕榈酸和甘油合成棕榈酸甘油三酯。取甘油、分离出的棕榈酸和脂肪酶在1.5mL离心管中进行反应。反应要求在60℃无溶剂下进行,反应时间为4h,甘油与棕榈酸的比例为1:4,加酶量为反应底物的8%。得到的产物棕榈酸甘三酯作为下一步合成OPO的底物。反应后得产物用丙酮溶解,离心分离去除酶和未反应的固体,取上清液稀释。反应结束后,取0.1g样品溶于1mL正己烷中,进行薄板层析。刮取甘三酯条带,溶于1mL正己烷中,进行液相检测,液相检测图谱见 figure 1 ,结果显示:在反应温度为60℃,反应时间为4h,甘油与棕榈酸的比例为1:4,加酶量为反应底物的8%条件下合成棕榈酸甘油三酯,产物经纯化后经HPLC检测纯度在80%以上。

[0044] 液相检测条件:Waters高效液相色谱仪;色谱柱:反相C18色谱柱;流动相:A相为丙酮,B相为乙腈,A、B相体积比为8:2,等度洗脱;流速:1mL·min-1;检测仪:示差折光检测器;色谱柱温:30℃;进样体积:10μL。

Embodiment 3

[0045] 实施例3 1,3-二油酸-2-棕榈酸甘油三酯的合成

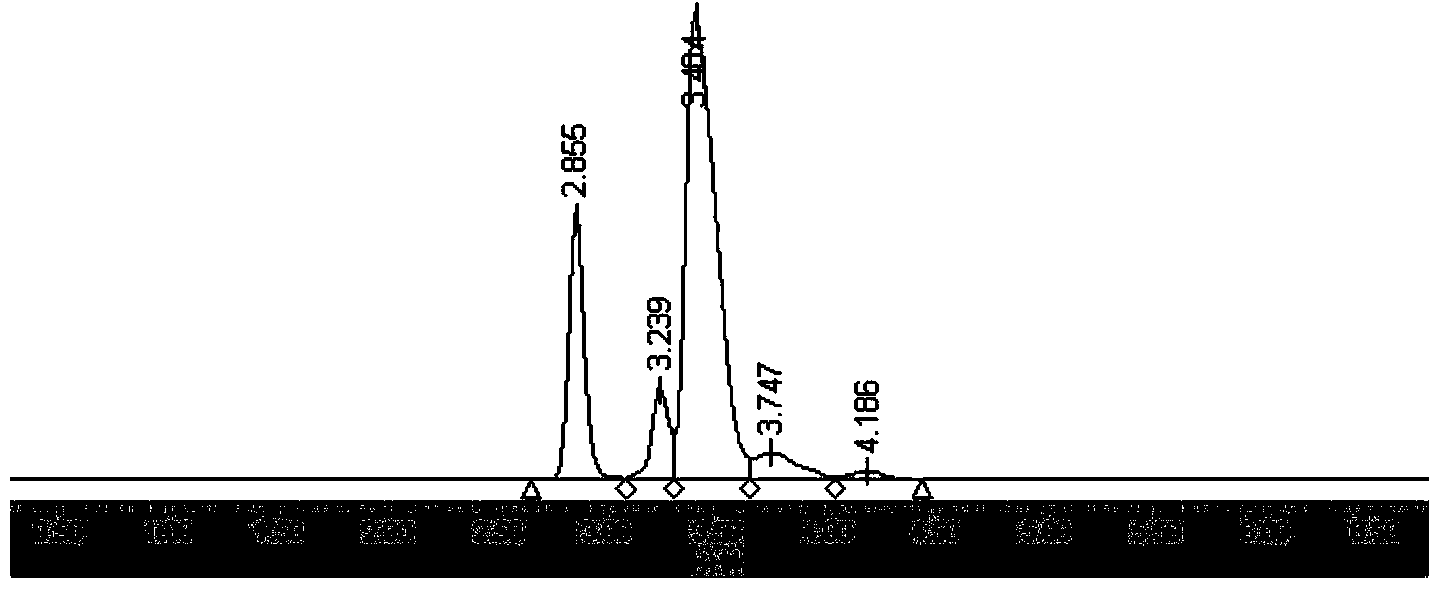

[0046] 取实施例2中合成的PPP,以及实施例1中分离纯化的油酸于1.5mL离心管内,加入sn-1,3特异性脂肪酶。在无溶剂条件下,置于60℃水浴锅中反应4h。在反应过程中定期取样进行液相检测。酸解反应完成后,通过离心分离去除反应产物中的脂肪酶,得到甘油三酯和脂肪酸的混合物。通过薄层层析分离甘油三酯和游离脂肪酸后,刮取甘油酯条带,溶于1mL正己烷中,进行液相检测,液相检测图谱见 figure 2 . 结果显示:在反应温度为60℃,反应时间为4h,底物摩尔比(OA / PPP)为4:1,加酶量为底物质量的7%条件下合成1,3-二油酸-2-棕榈酸甘油三酯,合成的1,3-二油酸-2-棕榈酸甘油三酯得率在40%以上,产物经HPLC检测,1,3-二油酸-2-棕榈酸甘油三酯的纯度在70%以上。

[0047] 液相检测条件:Waters高效液相色谱仪;色谱柱:反相C18色谱柱;流动相:A相为丙酮,B相为乙腈,A、B相体积比为8:2,等度洗脱;流速:1mL·min-1;检测仪:示差折光检测器;色谱柱温:30℃;进样体积:10μL。

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com