Radiant heating element, radiant heater and MOCVD reactor

A radiant heater, radiant heating technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problem of heating the substrate to 1400 ℃ and higher temperature, to improve the structure and increase the power Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

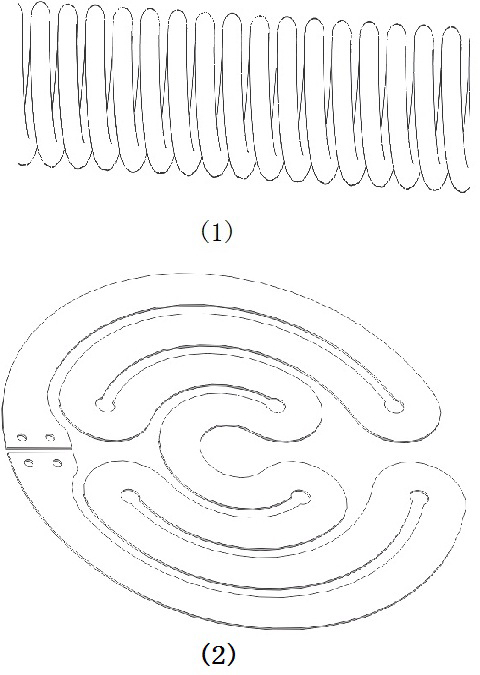

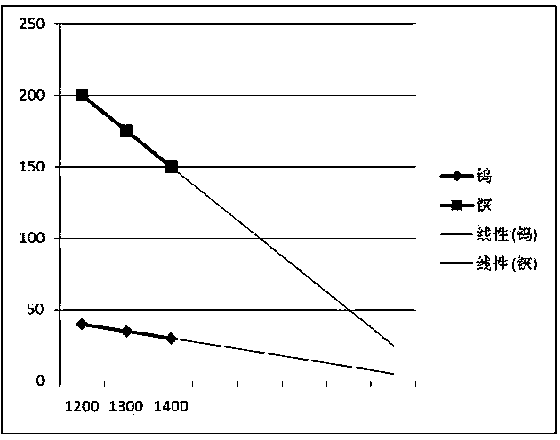

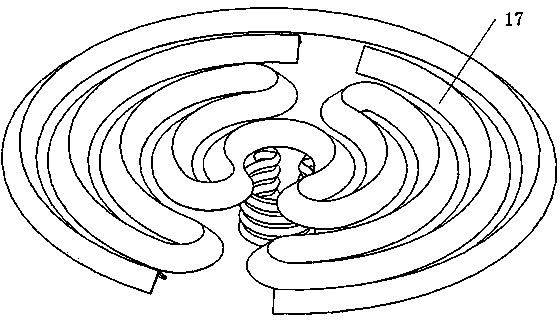

[0031] A radiant heating element, which is formed by winding a heating sheet 17 with axis symmetry, and the section of the heating sheet 17 is a special-shaped section, such as image 3 As shown, the section of the heating plate 17 is V-shaped; Figure 4 As shown, the section of the heating plate 17 is U-shaped; Figure 5 As shown, the section of the heating plate 17 is trapezoidal.

[0032] Such as Image 6 Shown, a kind of MOCVD reactor, comprises reactor housing 8, 4 groups of gas ports 1,2,3,4 of reactor housing 8 top surface and reactor housing 8 inner upper part is used for placing substrate 15 The substrate carrier 5, the radiation heater below the substrate carrier 5, the gas distribution device 6 on the top surface of the reactor shell 8, the center of the bottom of the substrate carrier 5 is provided with a rotating support shaft 11; the reactor shell The bottom of the body 8 is provided with a suction port 10 . The first gas interface 1 is connected to the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com