Hardener

A technology of hardener and complexing agent, applied in the field of hardener, can solve the problem of low hardness and achieve the effect of improving hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

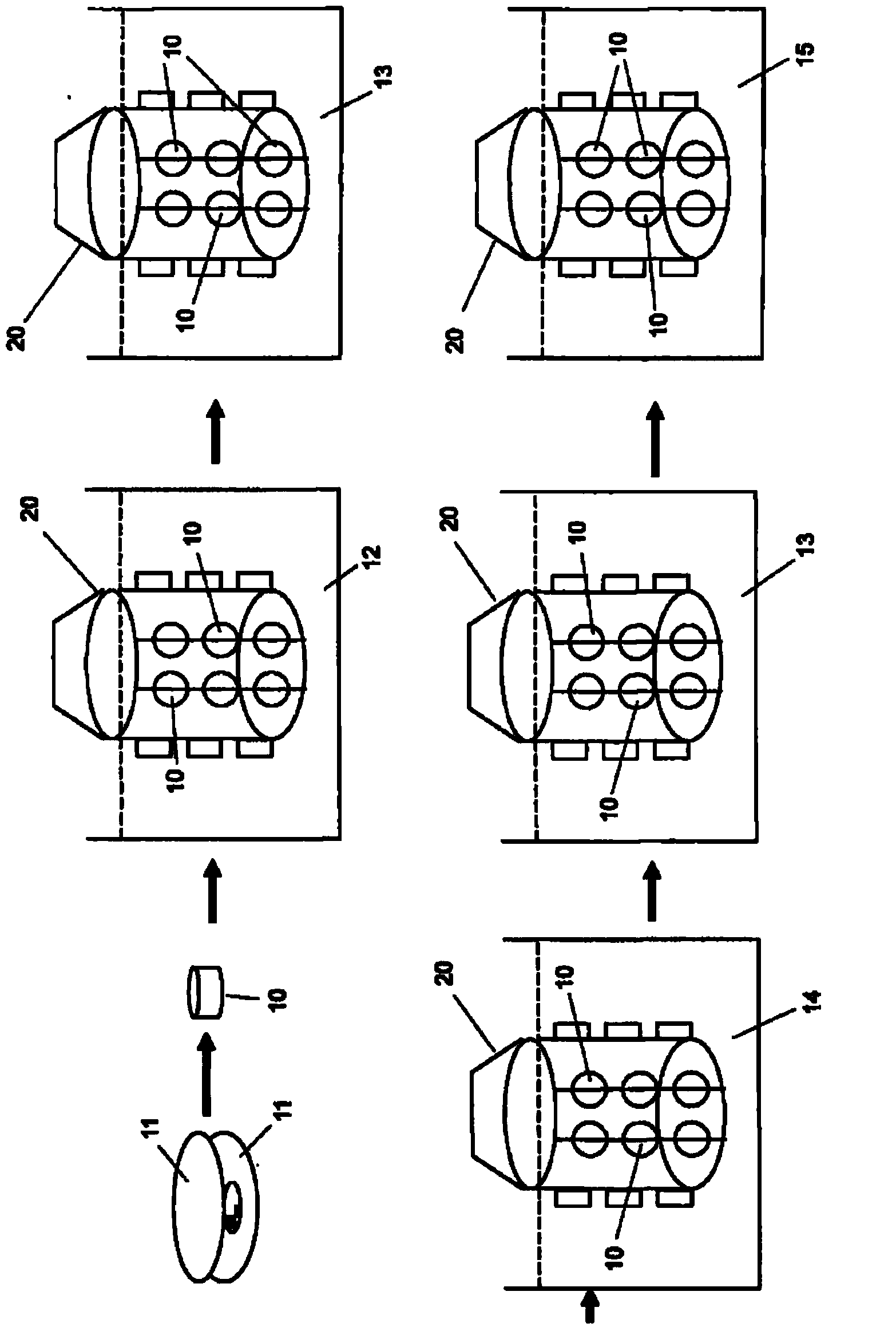

[0024] According to a specific embodiment of the present invention, the preparation method of the gold product comprises:

[0025] Electroplating a layer of gold on a mandrel formed of a low melting point material;

[0026] forming a hole through the electroplated layer to the mandrel, and melting the mandrel to exit through the hole; wherein the method of electroplating a gold layer on the mandrel comprises using the mandrel as a cathode, in Electroplating is performed in a cyanide-free plating solution and / or a cyanide-containing plating solution containing the above-mentioned hardener.

[0027] The mandrel mainly functions as a molding die, so that not only can various shapes of gold products be obtained, but also the gold products obtained after removing the mandrel have a hollow structure, so that the production of gold products of the same size can be significantly reduced. The amount of gold used in the finished product reduces the production cost. In the present inve...

Embodiment 1

[0039] This embodiment is used to illustrate the preparation method of hardener provided by the present invention and cyanide-free electroplating solution.

[0040] At 60°C, dissolve 200 grams of potassium phosphate, 100 grams of potassium monohydrogen phosphate, 50 grams of sodium sulfite, 0.5 grams of sodium antimony tartrate, 0.5 grams of sodium selenite and 5 grams of sodium edetate in 1 L of water to obtain hardened Agent Y1. At 60° C., 10 grams of sodium gold sulfite was uniformly mixed with hardener Y1 in terms of gold element to obtain cyanide-free electroplating solution Z1. The stability and conductivity of cyanide-free electroplating solution Z1 were determined by cyclic voltammetry, cathodic polarization curve and cathodic current efficiency method. The results show that the cyanide-free electroplating solution Z1 has high stability, only a very small amount of gold ions are automatically reduced, the conductivity is very good, and the cathode current efficiency i...

Embodiment 2

[0042] This embodiment is used to illustrate the preparation method of hardener provided by the present invention and cyanide-free electroplating solution.

[0043] Dissolve 180 g of sodium phosphate, 80 g of sodium monohydrogen phosphate, 40 g of potassium sulfite, 0.2 g of antimony potassium tartrate, 0.3 g of sodium selenosulfate and 2 g of thiourea in 1 L of water at 40°C to obtain hardener Y2 . At 60° C., 10 grams of gold potassium sulfite was uniformly mixed with the hardener Y2 to obtain the cyanide-free electroplating solution Z2. According to the method of Example 1, the stability and conductivity of the cyanide-free electroplating solution Z2 were tested. The results show that the cyanide-free electroplating solution Z2 has high stability, no automatic reduction of gold ions, better conductivity but lower than that of the cyanide-free electroplating solution Z1, and the cathodic current efficiency is maintained above 90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com