Built-in profiled steel sheet wall

A technology with built-in profiled and profiled steel plates, applied in walls, building components, buildings, etc., can solve the problems of unsatisfactory waterproof and seismic resistance, poor comprehensive effect, troublesome operation, etc. The effect of enhanced thermal insulation properties and simplified construction work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

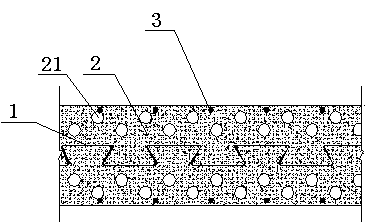

[0013] Such as figure 1 Shown are respectively the cross-sectional schematic diagrams of the built-in profiled steel plate wall of the present invention.

[0014] A built-in profiled steel plate wall includes two types of masonry wall and plate wall. The wall is provided with a built-in profiled steel plate 1 , and wall materials 2 are formed on both sides of the built-in profiled steel plate 1 .

[0015] Among them, the built-in profiled steel plate 1 is a coated thin steel plate that has been mechanically rolled and formed. The strength of the steel plate is implemented in accordance with the relevant specifications of the construction industry, and the coating of the steel plate is also implemented in accordance with the relevant specifications of the construction industry; the thickness of the steel plate is determined by calculation. Between 0.15 and 1.5 mm.

[0016] Wall material 2 is the current wall material, mainly sinter-free wall material, lightweight concrete (inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com