A piezoelectric crystal fuel injector and its injection control method

A technology of piezoelectric crystals and injectors, applied in the field of in-cylinder direct injection systems of aviation piston engines for small unmanned aerial vehicles, can solve the problems of small engine displacement, large system power consumption, and large number of components, and achieve fuel injection pressure High efficiency, low power consumption, precise fuel injection control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings.

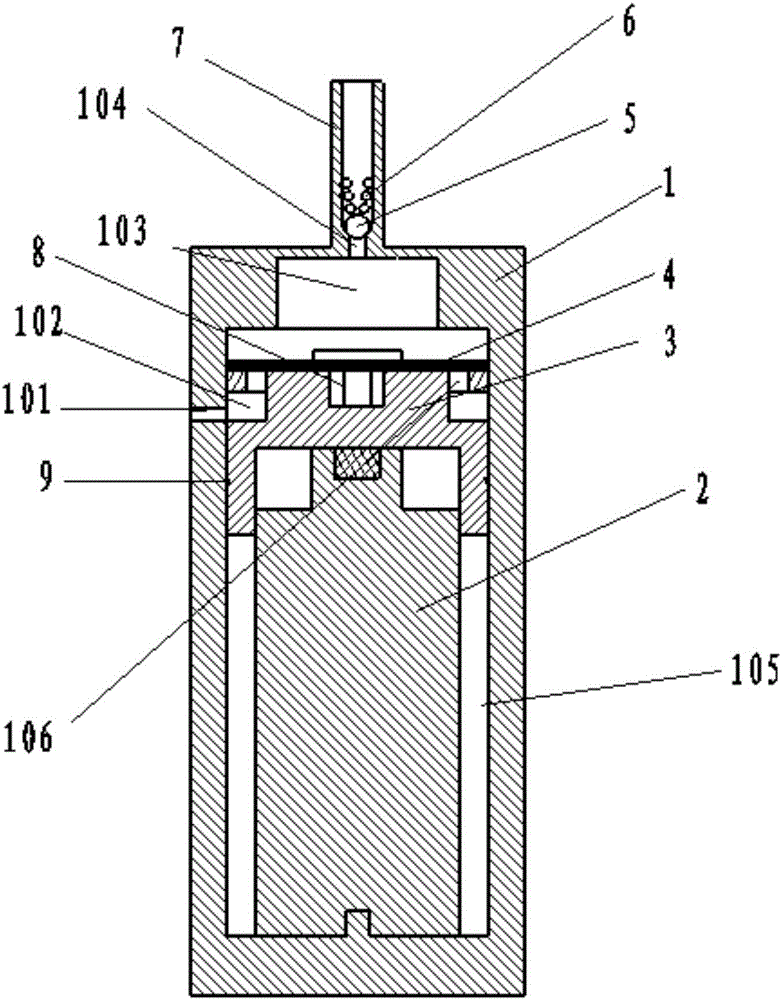

[0031] The present invention provides a highly integrated piezoelectric crystal fuel injector, such as figure 1 As shown, it includes housing 1, piezoelectric crystal actuator 2, piston 3, oil inlet reed valve 4, oil outlet one-way ball valve 5, conical spring 6, injection channel 7, reed fixing bolt 8, and sealing ring 9 .

[0032] The upper part of the housing 1 is a high-pressure oil chamber 103, the lower part is a piezoelectric crystal actuator chamber 105, and the low-pressure oil chamber 102; The piezoelectric crystal actuator 2 is at the bottom of the piezoelectric crystal actuator cavity 105 . The piston 3 is aligned with the oil inlet 101, the lower end of the piston 3 is in a vertically coupled state with the piezoelectric crystal actuator 2, and the piezoelectric crystal actuator 2 expands and deforms at the left and right sides of the trigger p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com