Hydraulic power pack structure of hydraulic press of jack

A technology of hydraulic pump station and press, applied in the field of press machinery, can solve the problems of difficult processing, complex valve body oil circuit structure, etc., and achieve the effect of simple structure and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

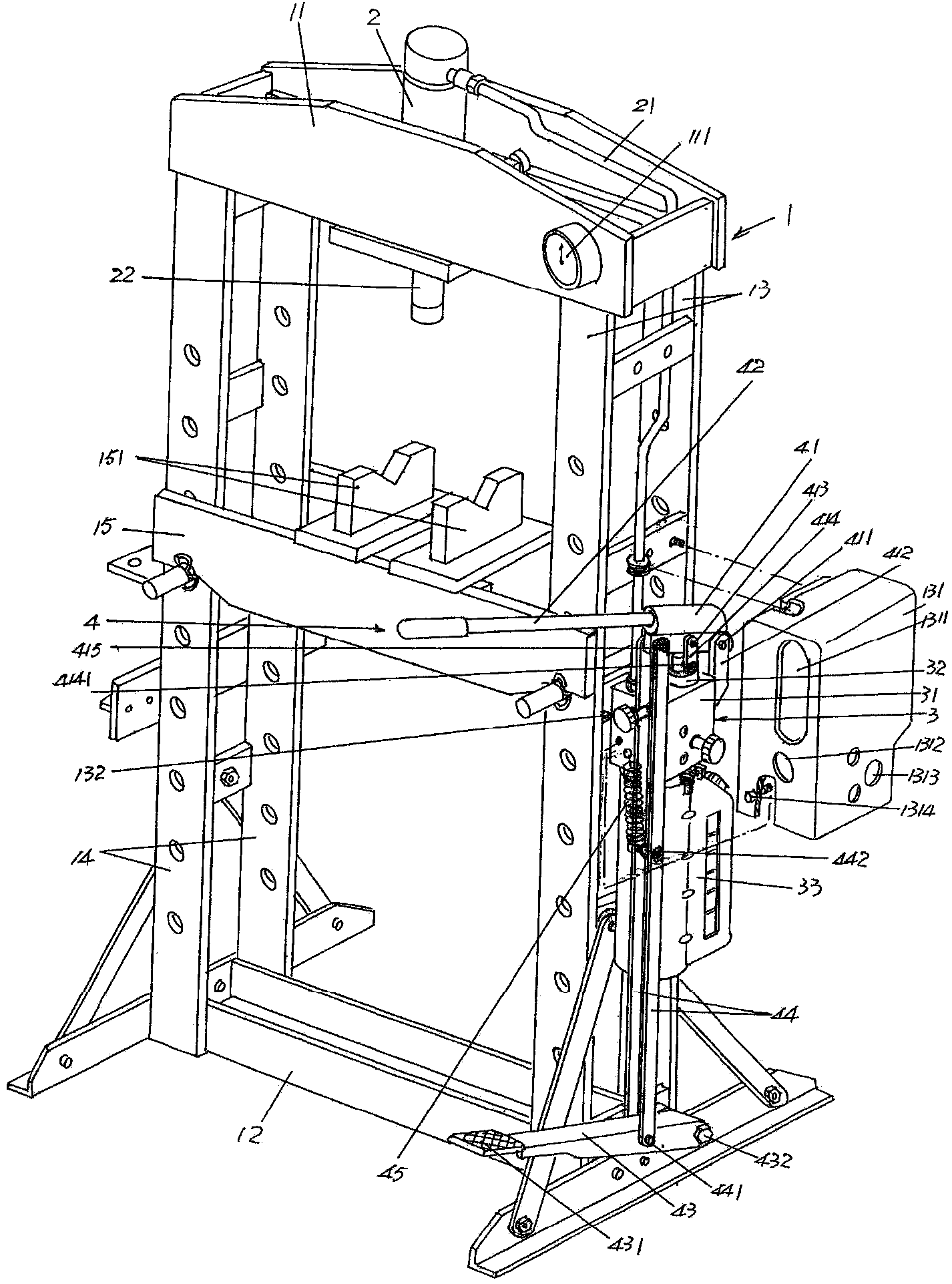

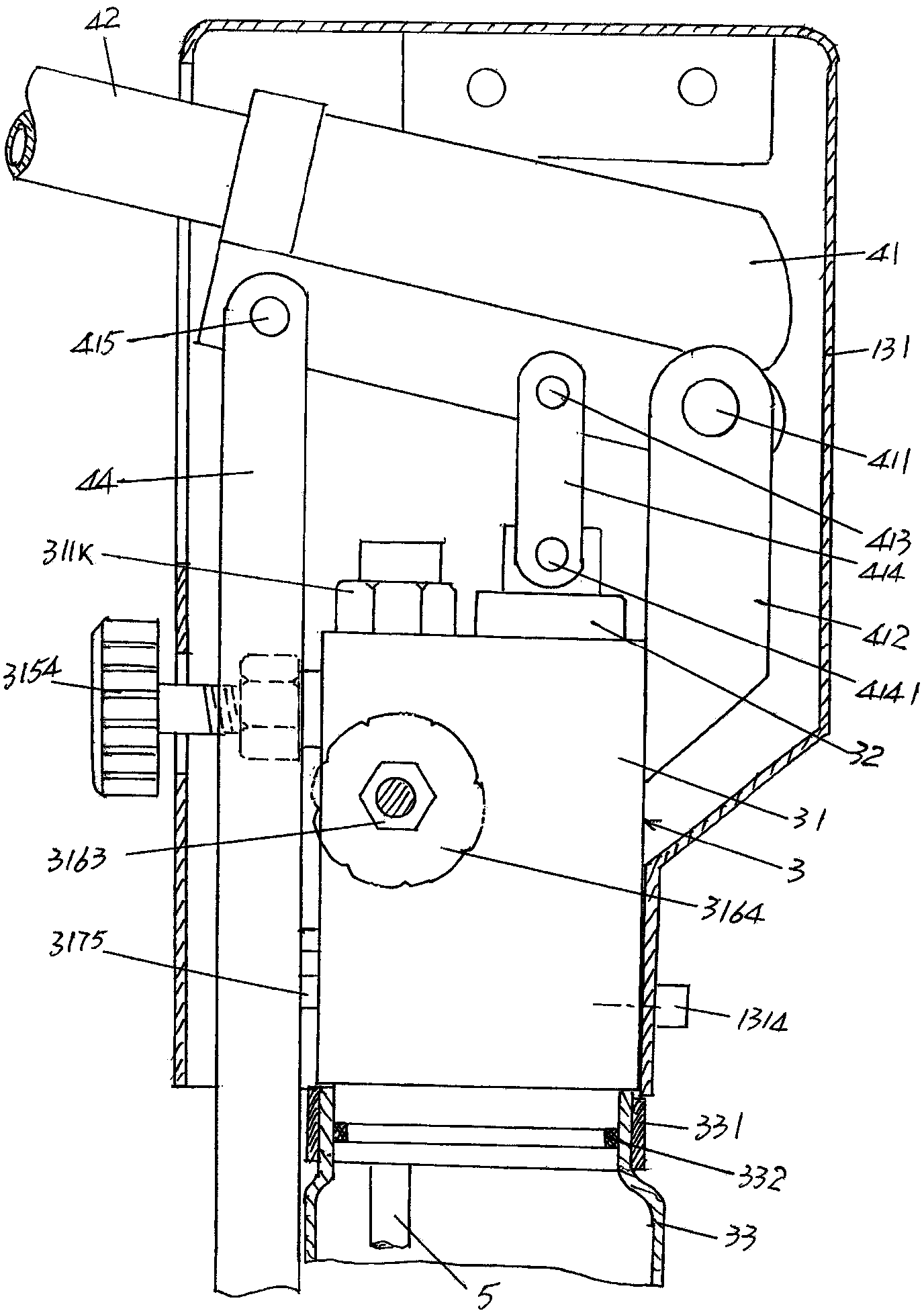

[0023] See figure 1 ,Should figure 1 A frame 1 is provided, which is composed of an upper beam 11, a lower beam 12, a first longitudinal arm 13, a second longitudinal arm 14 and a workpiece rack 15, and the upper and lower beams 11, 12 correspond to each other up and down, The upper end of the first longitudinal arm 13 is fixedly connected with the right end of the upper beam 11, and the lower end of the first longitudinal arm 13 is fixedly connected with the right end of the lower beam 12, and the upper end of the second longitudinal arm 14 is fixedly connected with the left end of the upper beam 11, and The lower end of the second longitudinal arm 14 is fixedly connected to the left end of the lower crossbeam 12, so that the frame 1 is formed by the upper and lower crossbeams 11, 12 and the first and second longitudinal arms 13, 14 parallel to each other longitudinally to form a structure similar to Chinese characters. The "mouth"-shaped structure, the workpiece frame 15 is...

Embodiment 2

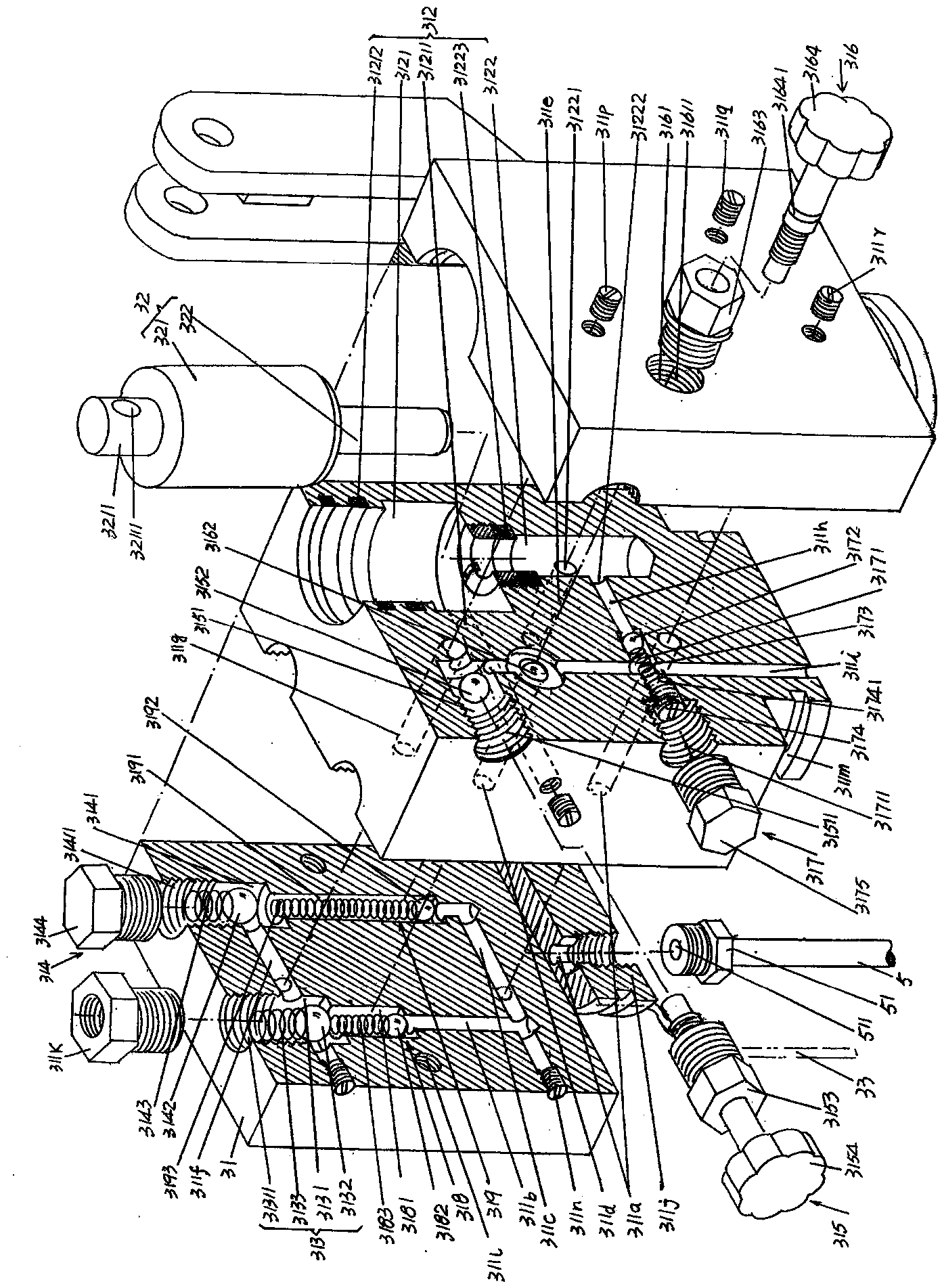

[0052] See Figure 5 , in the present embodiment, the small pump overpressure drain channel 311h is moved toward the direction of the oil return channel 311g of the working cylinder ( Figure 5 The state shown is shifted to the left), and the small pump overpressure oil discharge passage 311h is connected with the small pump inlet and outlet oil passage 311e, and a small pump overpressure valve connected to the small pump overpressure oil discharge passage 311h is set on the valve body 31 The oil return hole 311s of the oil drain channel, the oil return hole 311s of the small pump overpressure oil drain channel communicates with the oil storage tank 33 . Compared with the oil return passage 311i in Embodiment 1, this oil passage structure communicates with the oil return passage 311g of the working oil cylinder, the overpressure oil discharge passage 311h of the small pump, and the fast and slow speed control valve chamber 3161. The oil return passage 311i is only connected to...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap