Heat source flow equilibrium control device and using method thereof

A flow balance and control device technology, applied in heating methods, applications, household heating, etc., can solve the problems of large power consumption of circulating pumps, high procurement costs, and large boiler sizes, so as to save power consumption and reduce noise Pollution, reduce the effect of paving construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

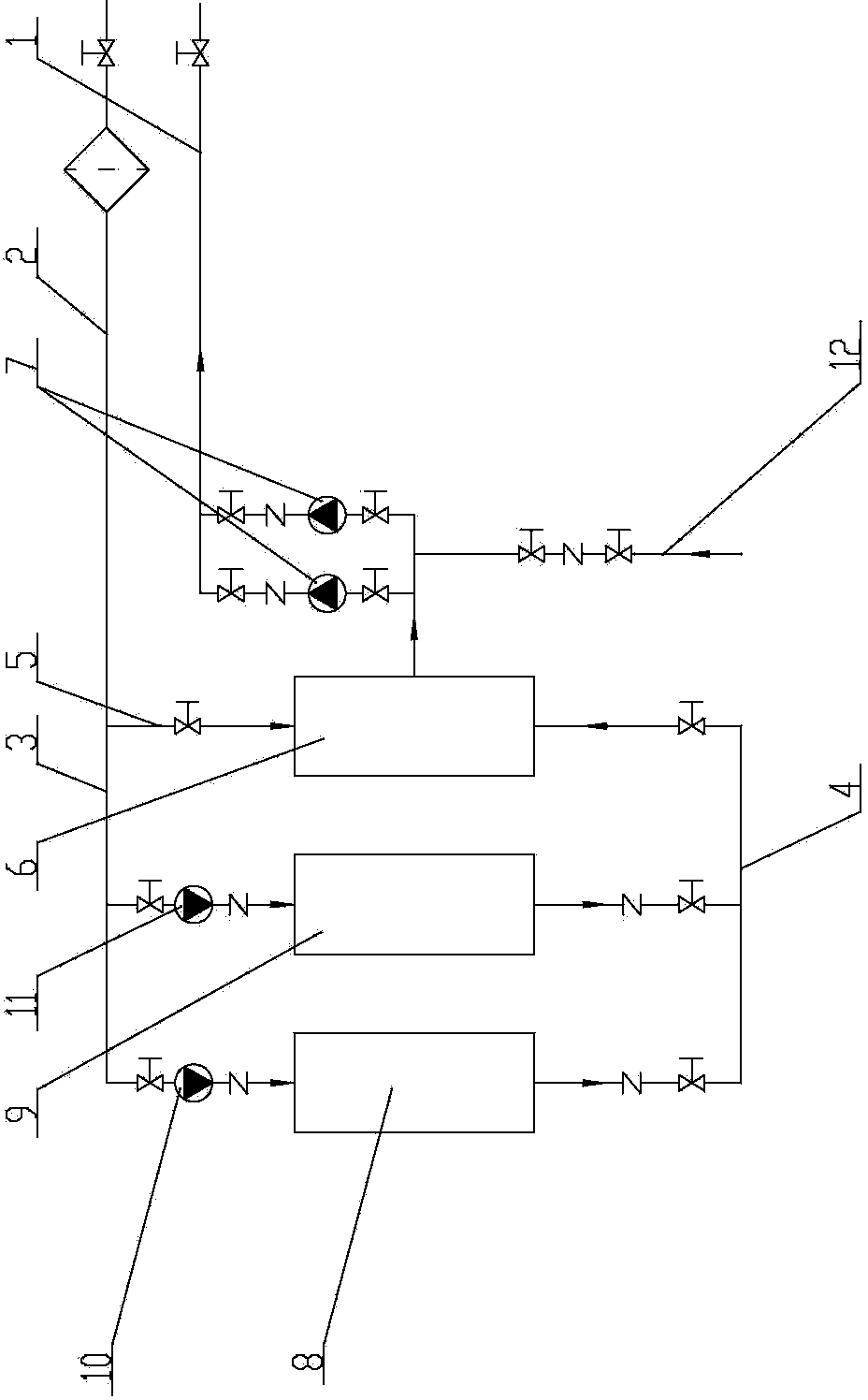

[0053] Embodiment one: as attached figure 1 As shown, the heat source flow balance control device includes a heat source section and a pipeline delivery section, wherein the pipeline delivery section includes a water supply main pipe 1 and a return water main pipe 2, and the heat source section includes a first branch 3, a second branch 4, and a third branch Road 5, energy mixing device 6 and gas boiler, the first branch 3 and the second branch 4 are connected by a gas boiler, the water inlet of the gas boiler is equipped with a boiler circulation pump, and the water outlet of the third branch 5 is connected to the The first water inlet of the mixing device 6 is connected, the end of the return water main pipe 2 is respectively connected with the water inlet of the third branch 5 and the water inlet of the first branch 3, and the water outlet of the second branch 4 is connected with the water mixing device The second water inlet of 6 is connected, and the water outlet of th...

Embodiment 2

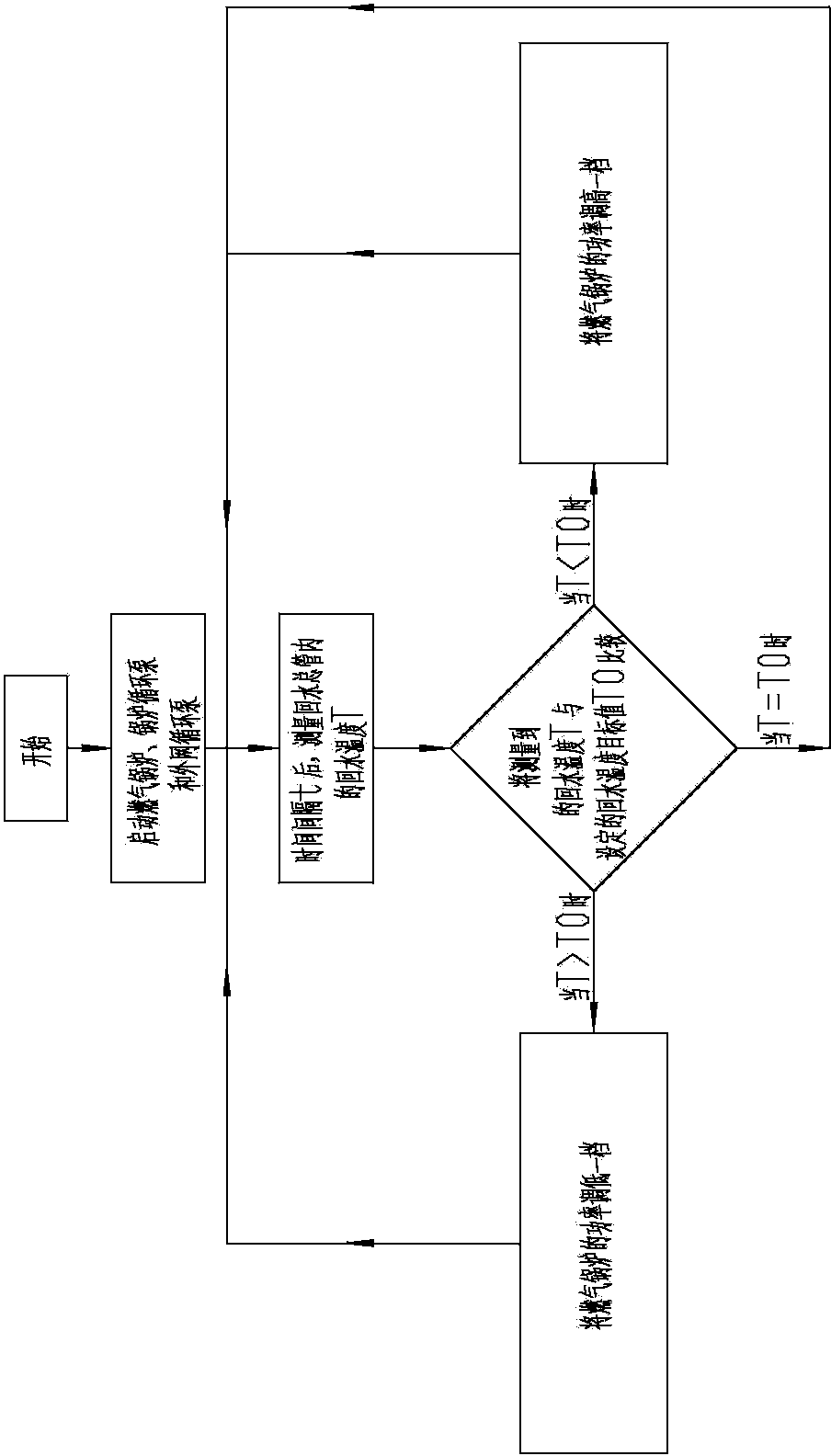

[0060] Embodiment two: as attached figure 1 , 2 As shown, a method of using the above-mentioned heat source flow balance control device is carried out according to the following steps:

[0061] The first step is to start the gas boiler, the boiler circulation pump and the external network circulation pump 7;

[0062] In the second step, after the time interval t, measure the return water temperature T in the return water main pipe 2;

[0063] The third step is to compare the measured return water temperature T with the set return water temperature target value T 0 Compare;

[0064] When T 0 , then increase the power of the gas boiler by one gear, and repeat the second and third steps;

[0065] When T=T 0 , repeat the second and third steps;

[0066] when T>T 0 , turn down the power of the gas boiler by one gear, and repeat the second and third steps.

Embodiment 3

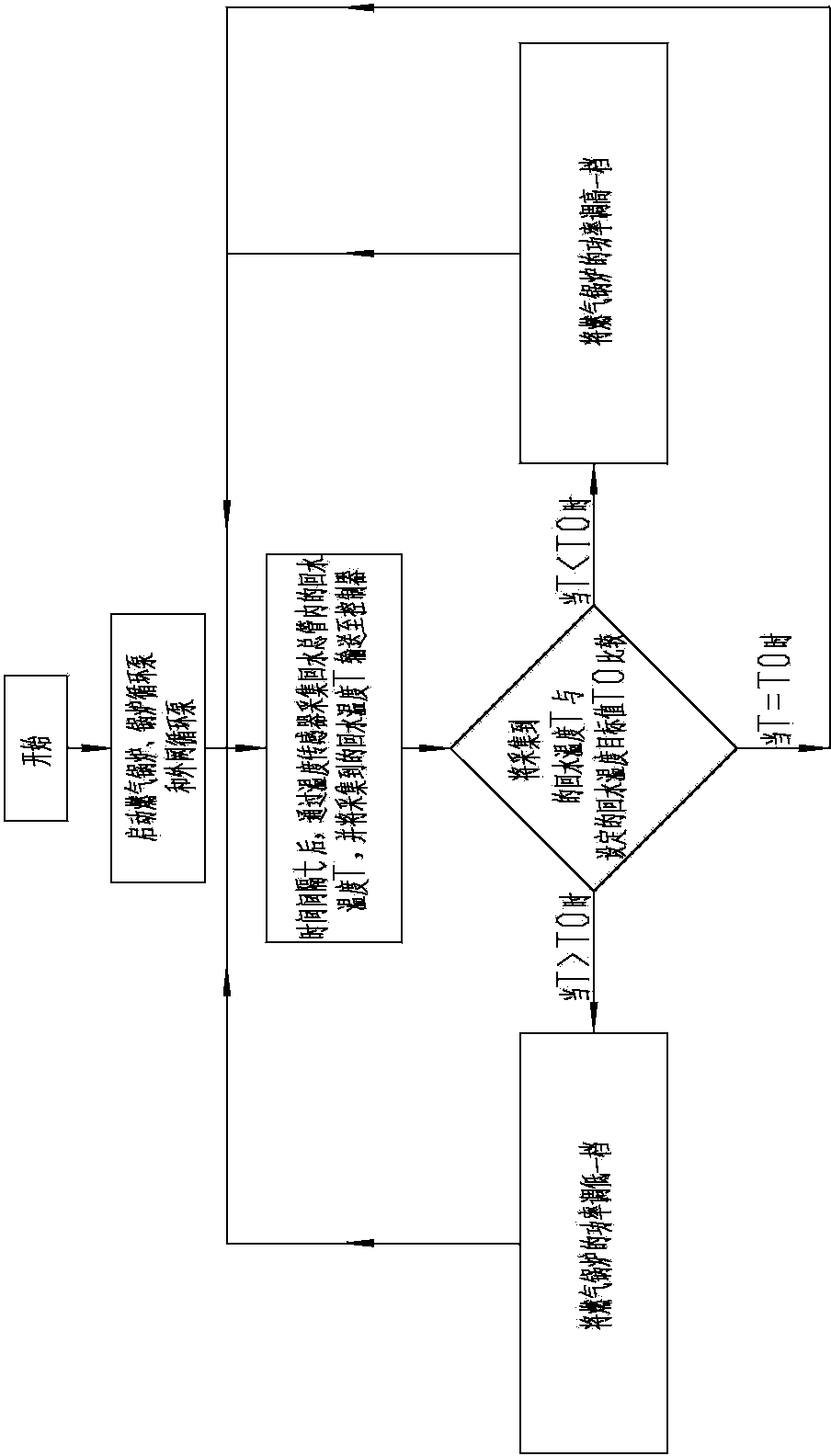

[0067] Embodiment three: as attached figure 1 , 3 As shown, a method of using the above-mentioned heat source flow balance control device is carried out according to the following steps:

[0068] The first step is to start the gas boiler, the boiler circulation pump and the external network circulation pump 7;

[0069] In the first step, after a time interval of t, the return water temperature T in the return water main pipe 2 is collected by the temperature sensor, and the collected return water temperature T is sent to the controller;

[0070] The second step is to compare the collected return water temperature T with the set return water temperature target value T 0 Compare;

[0071] When T 0 , then increase the power of the gas boiler by one gear, and repeat the second and third steps;

[0072] When T=T 0 , repeat the second and third steps;

[0073] when T>T 0 , turn down the power of the gas boiler by one gear, and repeat the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com