A kind of neutral gray-scale light reduction filter with multi-layer film layer and its manufacturing method

A neutral gray scale, multi-layer film technology, applied in the direction of optics, optical filters, optical components, etc., can solve problems such as ghost images easily, and achieve good effects, low reflectivity, and good light balance attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

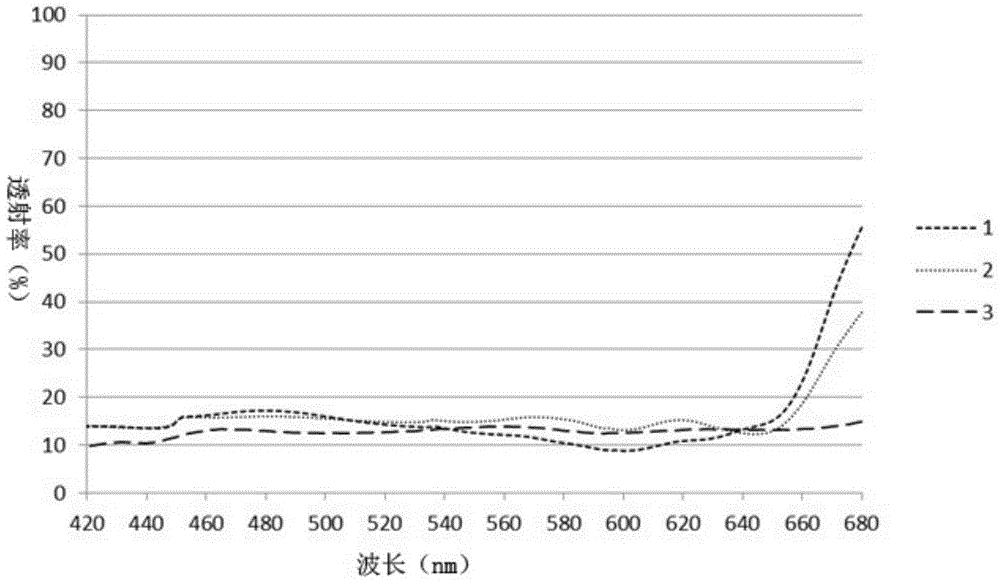

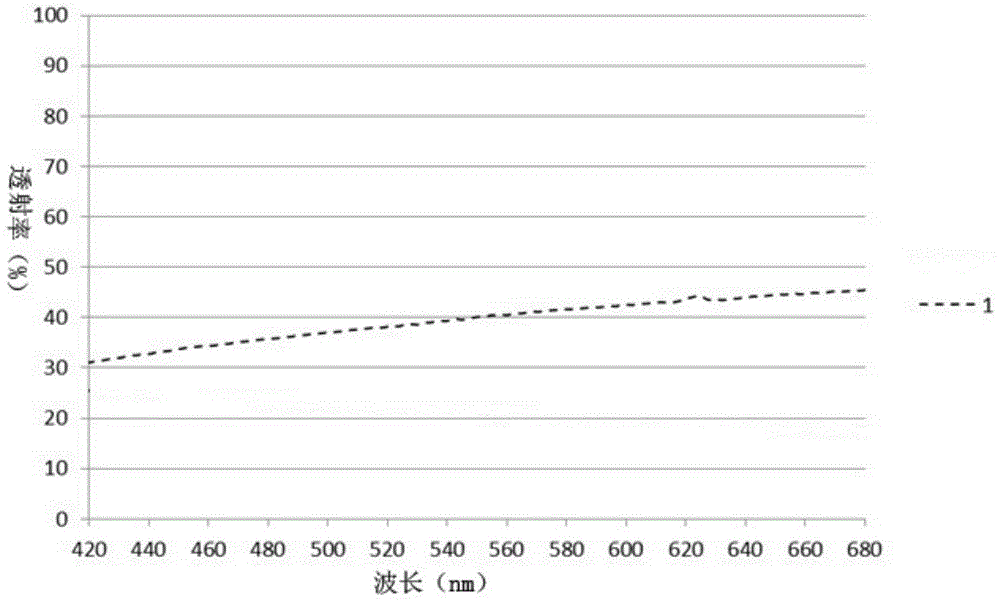

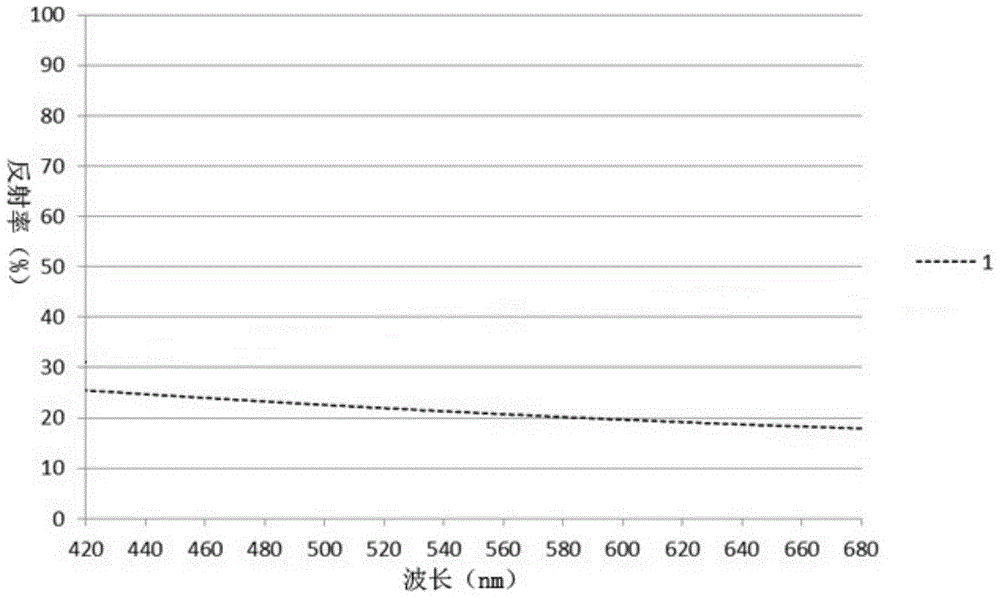

[0030] The neutral gray-scale light reduction filter of multi-layer film layer comprises a substrate, and several layers of film layers are coated on the substrate, and the film layer includes laminated anti-reflection films and metal films, and at least A layer of anti-reflection film, and a multi-layer anti-reflection film may also be provided between two adjacent metal films, and the refractive index of the constituent material of the anti-reflection film is greater than 1.30.

[0031] Preferably, the constituent material of the anti-reflection film includes at least one selected from Al2 o 3 , AlF 3 , BeO, CaF 2 , CeF 3 ,

[0032] CeO 3 、Cr 2 o 3 、Dy 2 o 3 、Gd 2 o 3 , HfO 2 、Ho 2 o 3 、In 2 o 3 、LaF 3 , MgF 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com