High-voltage rapid-soft-recovery diode and manufacturing method thereof

A soft recovery and diode technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problem of increased static power consumption of diode high-temperature leakage current, reverse recovery softness and reliability cannot be guaranteed, and it is difficult to obtain comprehensive Characteristics and other issues, to achieve the effect of increasing the terminal breakdown voltage, improving the reverse recovery softness factor, and reducing the surface electric field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

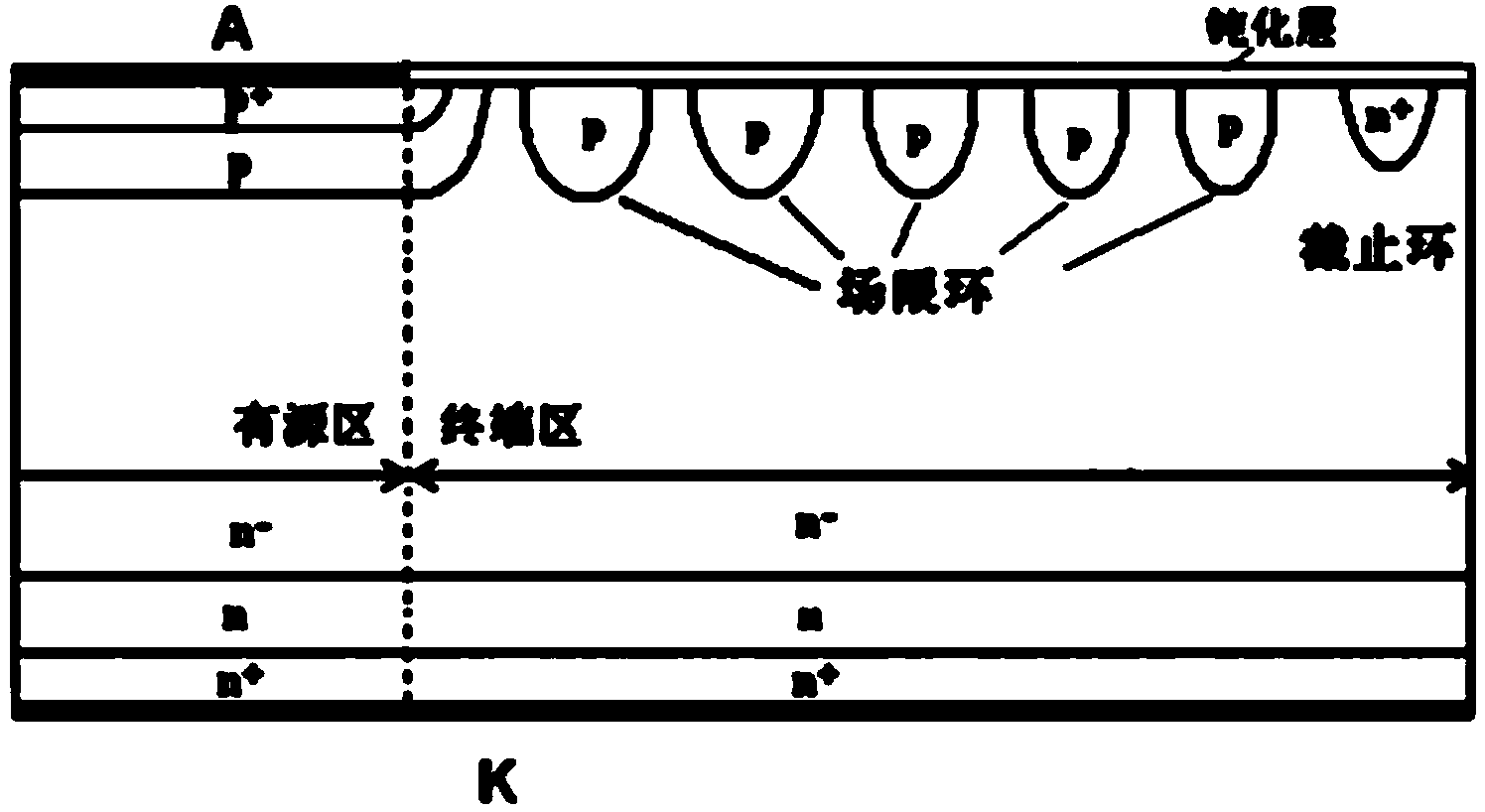

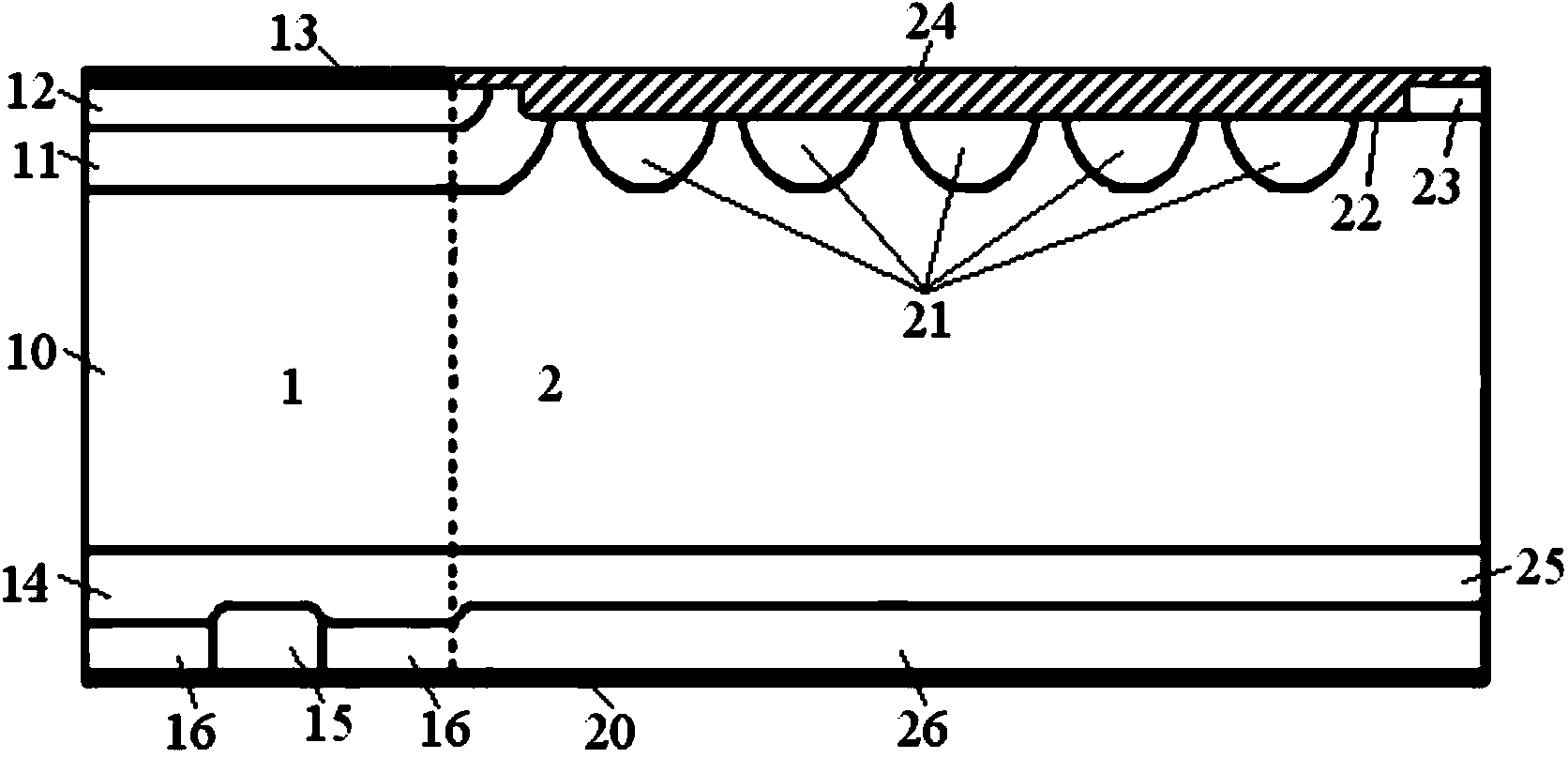

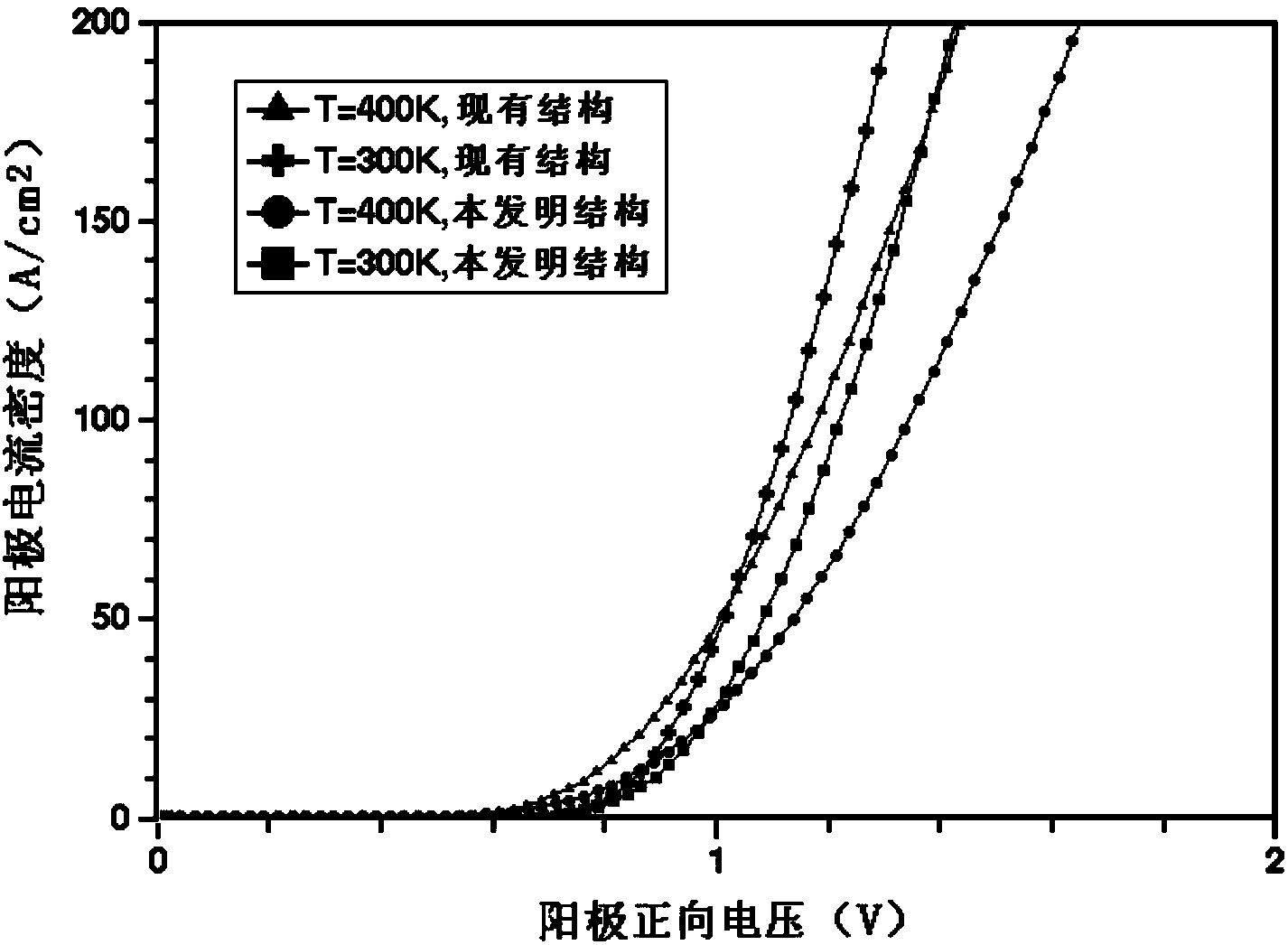

[0042] Such as figure 2 As shown, it is a high-voltage fast soft recovery diode according to the present invention, including a shared n - active region 1 and termination region 2 of substrate layer 10;

[0043] The active region 1 of n - The p buffer layer 11, p buffer layer 11, p + Anode layer 12 and anode aluminum electrode 13; with n - The lower surface of the substrate layer 10 is an active n-buffer layer 14 and a cathode aluminum electrode 20 arranged downwards in sequence, and also includes an active p buffer layer 14 and the cathode aluminum electrode 20 arranged between the active n + adjustment area 15 and two n of equal width + Cathode region 16, the active p + The adjustment area 15 is set at two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com