Adhesive tape and solar module and product made of same

A component and adhesive tape technology, applied in the field of solar component manufacturing, can solve the problems of increasing the weight and cost of solar components, complicated installation and operation, etc., and achieve the effect of reducing weight, reducing manufacturing cost, and good shock resistance and cushioning performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

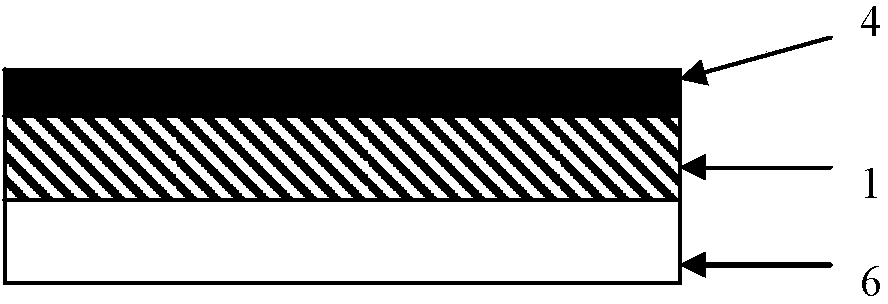

[0119] The structure of the adhesive tape of example 1 is as figure 1 shown. The film layer 4 and the release film 6 are respectively located on both sides of the substrate layer 1 . The materials of each layer are:

[0120] Film layer 4: Huasu 0.06mm black PVC (polyvinyl chloride) film

[0121] Substrate layer 1: 2081 acrylic foam rubber from 3M Company in the United States

[0122] Release film 6: Japan Mitsubishi Chemical Co., Ltd. 0.075mm PE release film

[0123] The preparation process of the adhesive tape is as follows:

[0124] 3M2081 acrylic foam rubber is coated on the 0.075mm PE (polyethylene) release film of Mitsubishi Chemical Co., Ltd. through a solvent-free coating process to form a substrate layer. After the coating is completed, the substrate layer is bonded to the inner surface of the Huasu 0.06mm black PVC film to obtain the finished tape.

example 2

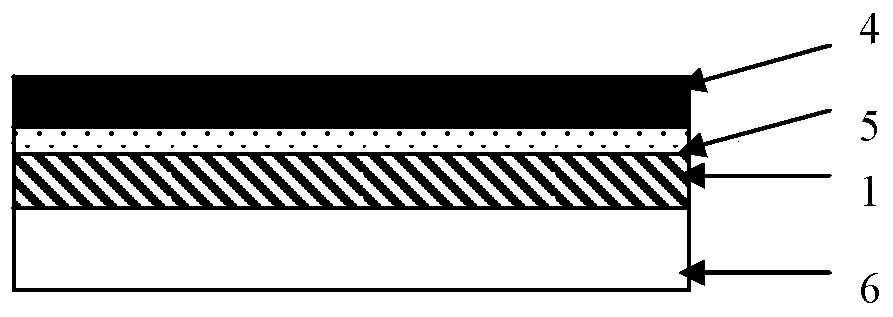

[0126] The structure of the adhesive tape of example 2 is as figure 2 shown. Both sides of the substrate layer 1 are respectively provided with an undercoat layer 5 and a release film 6 , and a film layer 4 is arranged on the top of the undercoat layer 5 . The materials of each layer are:

[0127] Film layer 4: Huasu 0.10mm black PVC film

[0128] Base coat 5: POLYMENT NK-350

[0129] Substrate layer 1: 3M2081 acrylic foam glue

[0130] Release film 6: Mitsubishi Chemical Corporation 0.075mm PP (polypropylene) release film

[0131] The preparation process of the adhesive tape is as follows:

[0132] 3M2081 acrylic foam adhesive is coated on the 0.075mm PE release film of Mitsubishi Chemical Co., Ltd. through a solvent-free coating process to form a substrate layer. The coating of the base coat was carried out on the tie layer of Huasu 0.10 mm black PVC film. After finishing the coating, the substrate layer is laminated with the primer layer on the Huasu 0.10mm black PV...

example 3

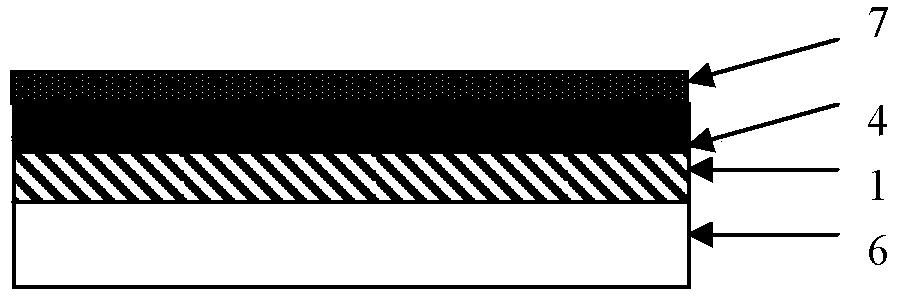

[0134] The structure of the adhesive tape of example 3 is as image 3 shown. A film layer 4 and a release film 6 are arranged on both sides of the substrate layer 1 respectively, and a top layer 7 is arranged on the top of the film layer 4 . The materials of each layer are:

[0135] Top layer 7: MOMENTIVE PERFORMANCE MATERIALS "UVHC8558"

[0136] Film layer 4: Huasu 0.10mm black PVC film

[0137] Substrate layer 1: 3M2081 acrylic foam glue

[0138] Release film 6: Tongli 0.150mm PE release film

[0139] The preparation process of the adhesive tape is as follows:

[0140] 3M2081 acrylic foam adhesive is coated on Tongli 0.150mm PE release film to form a substrate layer through a solvent-free coating process. On the outer surface layer of Huasu 0.10mm black PVC film, the bottom surface hardening layer MOMENTIVE PERFORMANCE MATERIALS "UVHC8558" is coated. After finishing coating, the substrate layer is bonded to the inner surface of Huasu 0.10mm black PVC film to complete ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com