An anti-corrosion steel pipe lined with stainless steel end sleeve automatic argon arc welding machine

A technology of anti-corrosion steel pipe and argon arc welding machine, which is applied in the direction of arc welding equipment, welding equipment, welding equipment, etc., which can solve the problems of high labor intensity, poor welding quality, and slow welding speed for operators, and achieve convenient and fast positioning and labor The effect of low strength and fast welding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

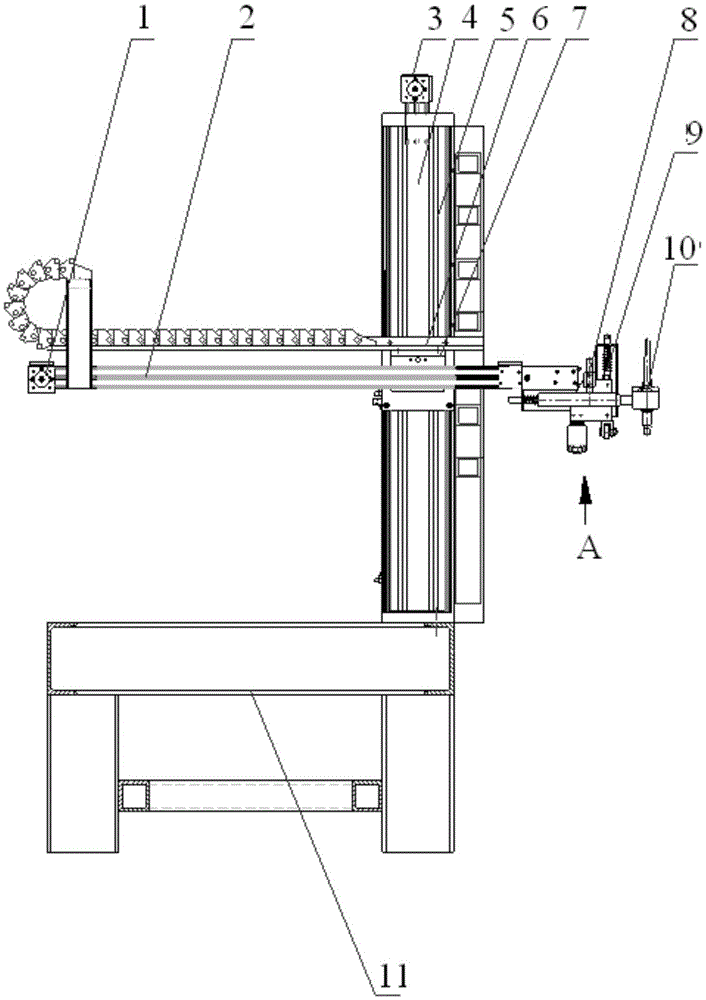

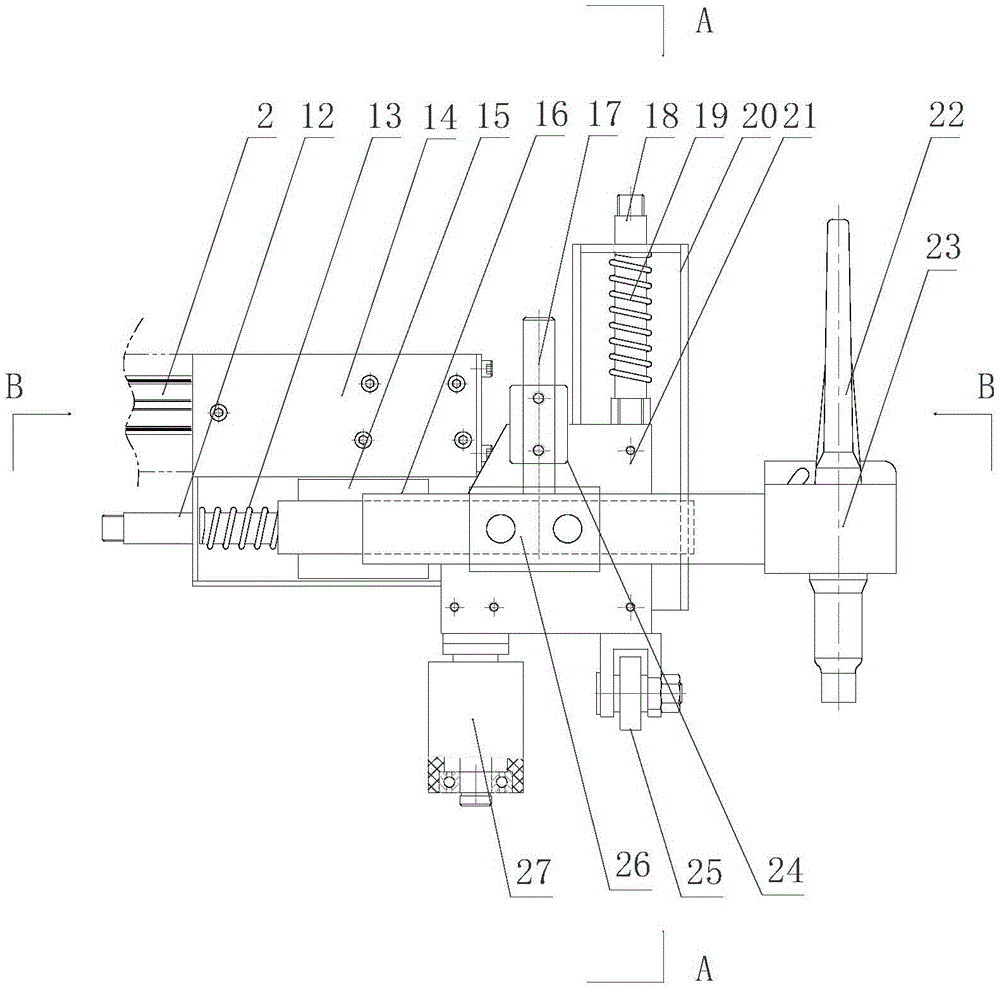

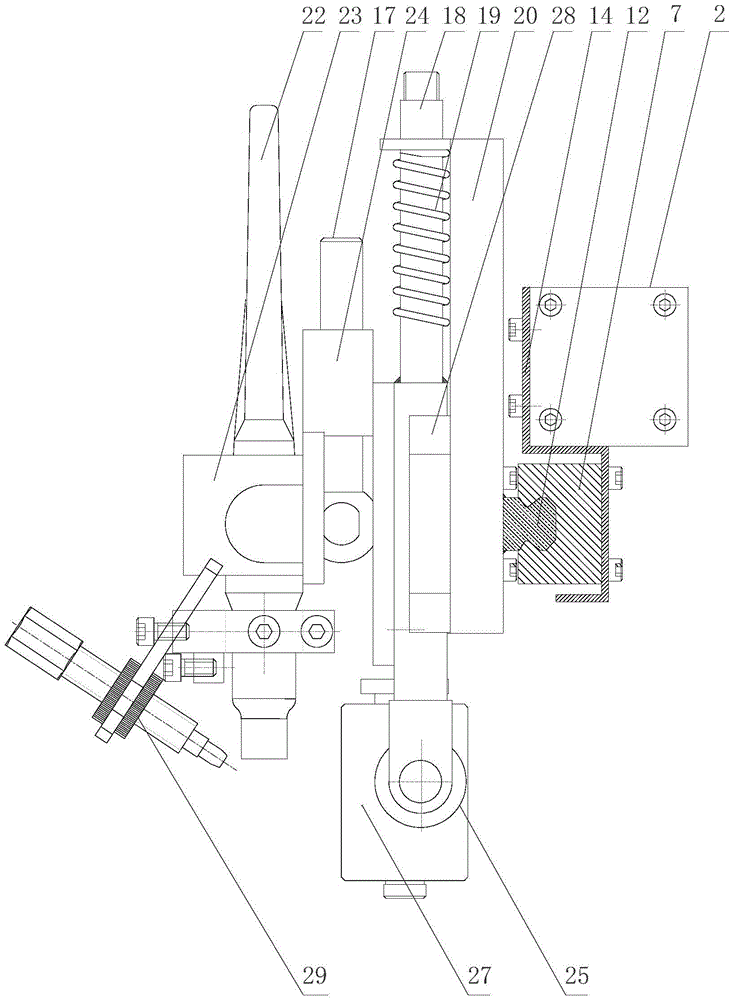

[0020] An anti-corrosion steel pipe lined with stainless steel end sleeve automatic argon arc welding machine, which is composed of a base 11, a vertical lifting device, a lateral moving device, an automatic fine-tuning device 9, a manual fine-tuning device 8, an argon arc welding torch device 10, and a microcomputer control device. The vertical lifting device is fixed on the base, the horizontal moving device is slidingly installed on the vertical lifting device, the automatic fine-tuning device is fixed on the horizontal moving device, the manual fine-tuning device is fixed on the automatic fine-tuning device, and the argon arc welding torch device is set on the manual fine-tuning On the device, the microcomputer control device is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com