A kind of heating device and heating method for asphalt in asphalt well

A technology of a heating device and a heating method, applied in the direction of transporting passenger cars, tank cars, railway car body parts, etc., can solve the problems of air bubbles, rising surface temperature of electric heating elements, mixing of water, etc., to facilitate handling work and prevent excessive temperature. , to avoid the effect of asphalt aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

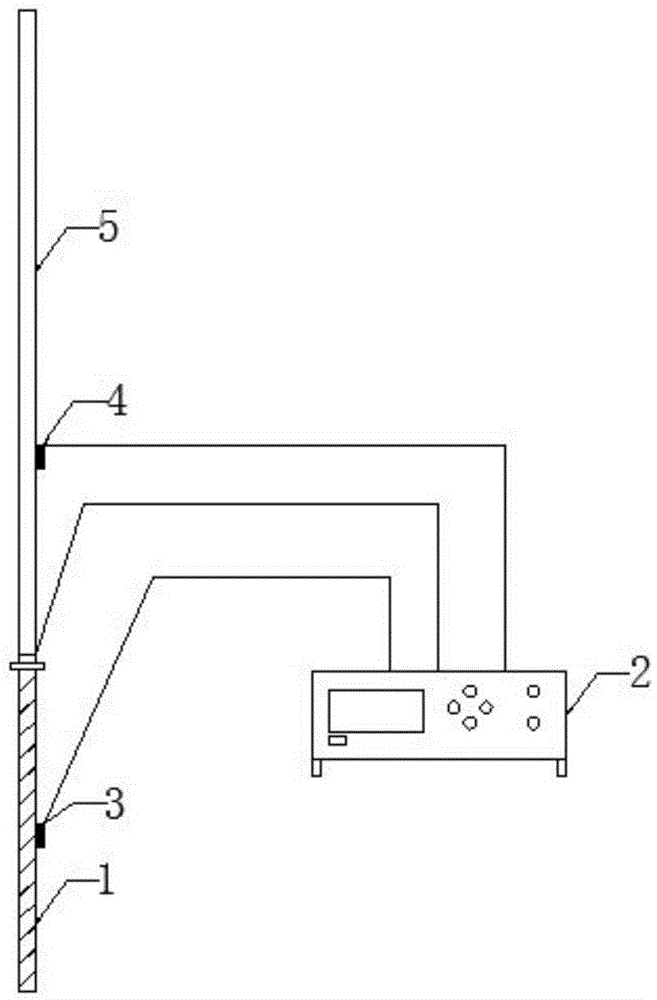

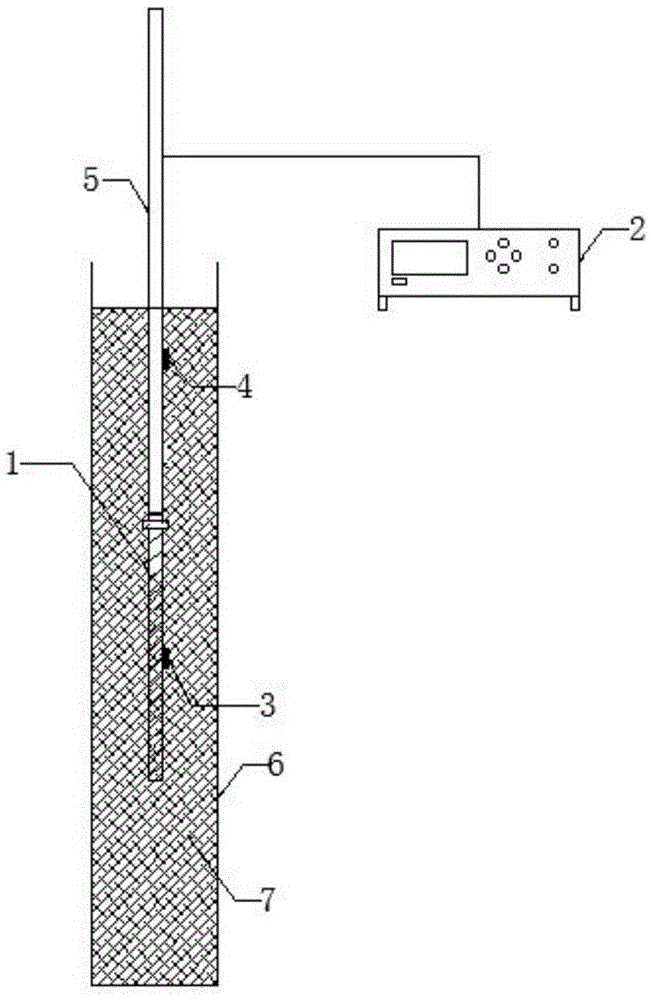

[0026] Such as figure 1 As shown, the present invention provides a heating device for asphalt in an asphalt well, including an electric heating element 1, a temperature controller 2, a first temperature sensor 3, a second temperature sensor 4 and an operating rod 5, wherein the first temperature sensor 3 is installed On the electric heating element 1, it is used to sense the surface temperature of the electric heating element 1; the length of the operating rod 5 is adjustable, one end is a fixed end, and the other end is a free end, and the specific operating rod can be designed as a telescopic structure, or It is connected at its free end to realize the adjustment of the length, the fixed end of the operating rod 5 is connected to the top of the electric heating element 1, and the second temperature sensor 4 is fixed on the operating rod 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com