A method for removing impurities phosphorus and boron in metal silicon

A technology for metal silicon and impurities, which is applied in the field of solar-grade polysilicon purification, can solve the problem that the phosphorus removal effect needs to be improved, etc., and achieve the effects of convenient industrial production, easy operation and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

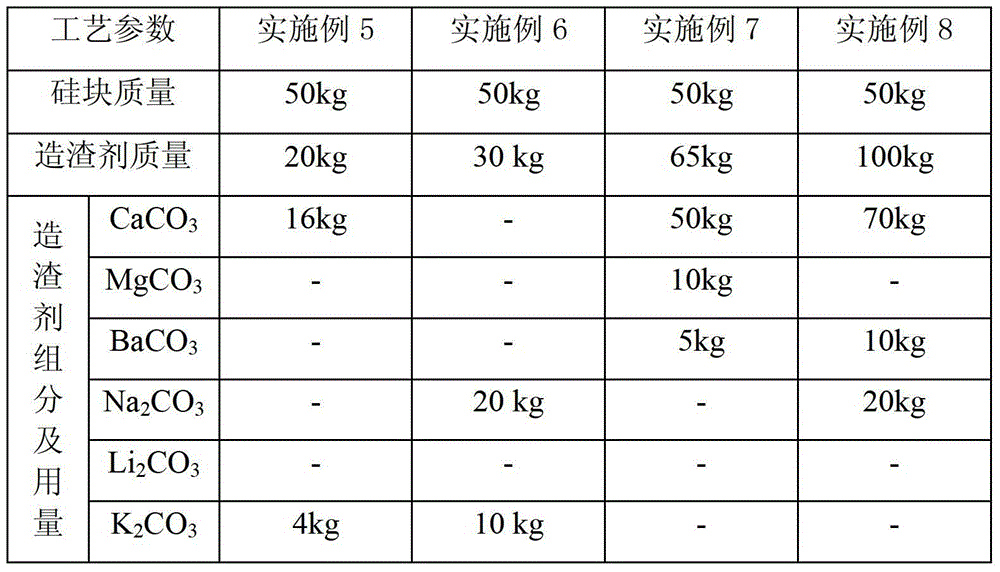

Examples

Embodiment 1

[0032] Weigh 50kg of raw industrial silicon, put the silicon block into a graphite crucible of an intermediate frequency induction furnace and heat it, and melt it into a silicon liquid at a heating temperature of 1700°C; weigh 50kg of a slagging agent, of which CaCO 3 The weight is 40kg, Na 2 CO 3 The weight is 5kg, K 2 CO 3 The weight is 4kg, the rest is Li 2 CO 3 , put the slagging agent into the silicon liquid, and continue heating to completely melt the slagging agent; preheat the graphite rod with the vent hole, insert the vent rod into the silicon liquid after the preheating is sufficient, and start stirring with argon gas, The flow rate of the argon gas is 12L / min, and the aeration time is 20min. After the reaction is complete, it is kept for 30min at a temperature of 1600°C; After the silicon ingot is cooled, remove the slag on the surface of the silicon ingot; crush and grind the silicon ingot, and the particle size of the silicon powder is 60-200 mesh; use mixe...

Embodiment 2

[0034] Weigh 50kg of raw industrial silicon, put the silicon block into a graphite crucible of an intermediate frequency induction furnace and heat it, and melt it into a silicon liquid at a heating temperature of 1500°C; weigh 60kg of a slagging agent, of which CaCO 3 The weight is 30kg, MgCO 3 The weight is 6kg, Na 2 CO 3 The weight is 14kg, the rest is K 2 CO 3 , put the slagging agent into the silicon liquid, and continue heating to completely melt the slagging agent; preheat the graphite rod with the vent hole, insert the vent rod into the silicon liquid after the preheating is sufficient, and start stirring with argon gas, The flow rate of the argon gas is 5L / min, and the aeration time is 15min. After the reaction is complete, keep it warm for 20min at a temperature of 1650°C; After the silicon ingot is cooled, remove the slag on the surface of the silicon ingot; crush and grind the silicon ingot, the particle size of the silicon powder is 80-160 mesh; use mixed acid...

Embodiment 3

[0036]Weigh 50kg of raw industrial silicon, put the silicon block into a graphite crucible of an intermediate frequency induction furnace and heat it to melt into silicon liquid at a heating temperature of 1550°C; weigh 75kg of slagging agent, of which CaCO 3 The weight is 60kg, MgCO 3 The weight is 11.25kg, and the rest is K 2 CO 3 , put the slagging agent into the silicon liquid, and continue heating to completely melt the slagging agent; preheat the graphite rod with the vent hole, insert the vent rod into the silicon liquid after the preheating is sufficient, and start stirring with argon gas, The flow rate of the argon gas is 10L / min, the aeration time is 60min, after the reaction is complete, the holding time is 30min, and the holding temperature is 1700°C; then the silicon liquid after the reaction is poured into a crystallizer with a heating function to slowly solidify, After the silicon ingot is cooled, remove the slag on the surface of the silicon ingot; crush and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com