Adjustable annular double-layer air bag hole sealing device and method for performing hole sealing

A double-layer airbag and hole-sealing device technology, which is applied in the directions of safety devices, sealing/seal, earthwork drilling, etc., can solve the problems of small application range and poor sealing effect, achieve wide application range, simplify manufacturing and labor The effect of intensity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

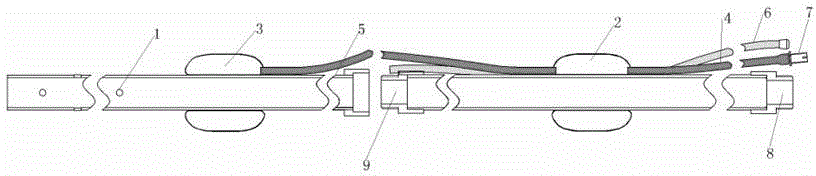

[0015] Such as figure 1 As shown, an adjustable annular double-layer airbag sealing device includes:

[0016] Main pipeline: metal material or non-metal material, used to connect grouting, drainage and air extraction pipelines after sealing. When the pipeline exceeds 6m, it can be divided into two sections, and when the pipeline exceeds 9m, it can be divided into three sections, and the middle is connected by internal and external wires (screws), with an outer diameter of 50-100mm. In order to increase the friction between the pipe and the annular airbag, use a lathe to process a 40-70 mm long thread at the place where the annular airbag is installed. The place where the annular airbag is installed is generally 1-3m away from both ends of the pipe. depending on the position of the hole section);

[0017] The first annular double-layer airbag and the second annular double-layer airbag: the annular airbag is made of rubber material, the length is 20-50cm, the inner diameter i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com