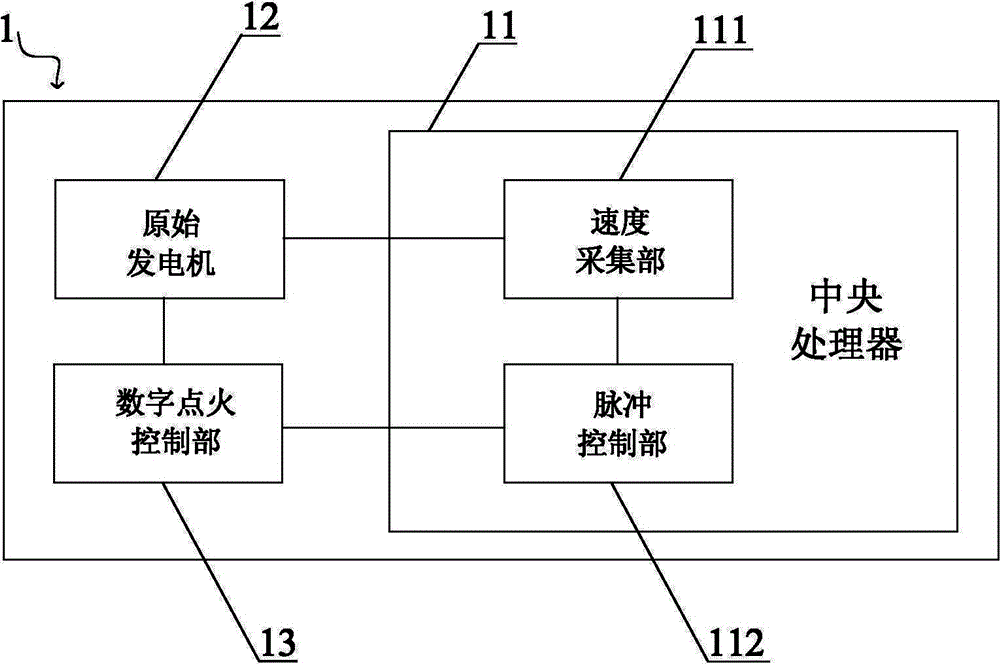

Digital generator system

A digital generator and generator technology, applied in the direction of electrical automatic control, automatic control, automatic control, etc., can solve the problems of digital generator noise, fuel consumption and emission pollution restrictions under working conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

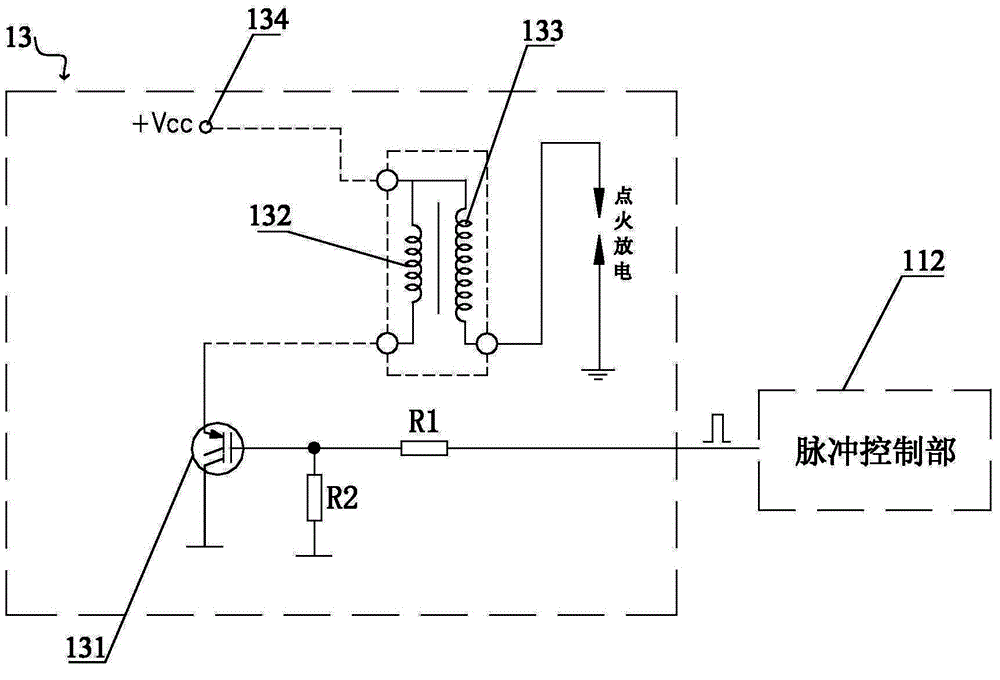

Embodiment 1

[0023] figure 2 It is a circuit diagram of the digital ignition control part of the first embodiment of the present invention. Such as figure 2 As shown, the digital generator system of this embodiment adopts a transistor-type digital ignition control part, and the digital ignition control part 13 includes: a first switching device 131, a first ignition primary coil 132, a first ignition secondary coil 133, and A power supply 134 for energizing the first ignition primary coil 132 . The first switching device 131 can be a Darlington tube or an IGBT tube, connected between the pulse control part 112 and the first ignition primary coil 132, and the first switching device 131 realizes on / off according to the first pulse signal, when When the first pulse signal is at a high level, the first switch device 131 is turned on; when the first pulse signal is at a low level, the first switch device 131 is turned off. The first ignition primary coil 132 generates electromagnetic induc...

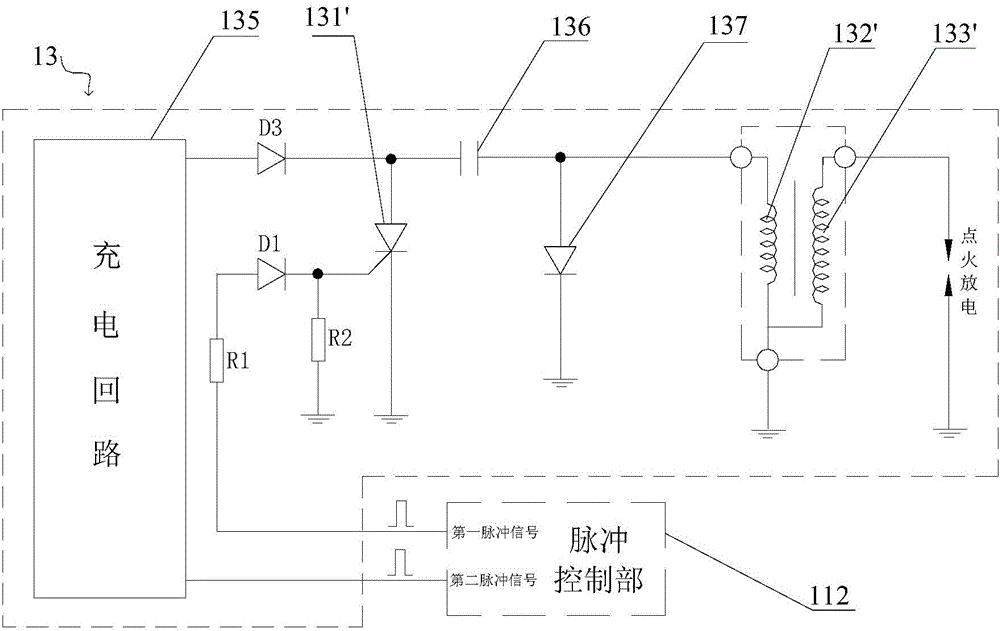

Embodiment 2

[0026] image 3 It is a circuit diagram of the digital ignition control part of the second embodiment of the present invention. Such as image 3As shown, the digital generator system of this embodiment adopts a capacitive digital ignition control part, and the digital ignition control part 13 includes: a charging circuit 135, a second switching device 131', an ignition capacitor 136, a second ignition primary coil 132', a first Two ignition secondary coils 133 ′ and a first diode 137 . The charging circuit 135 is connected between the pulse control unit 112 and one end of the ignition capacitor 136 to charge the ignition capacitor 136 , and the pulse control unit 112 controls the charging circuit 135 to charge the ignition capacitor 136 by sending out a second pulse signal. The second switching device 131' can be a silicon-controlled rectifier element, connected between the pulse control part 112 and the one end of the ignition capacitor 136, and realizes on / off according to...

Embodiment 3

[0029] Figure 4 It is a circuit diagram of the digital ignition control part of the third embodiment of the present invention. Such as Figure 4 As shown, the digital generator system of this embodiment adopts a capacitive digital ignition control part, and the digital ignition control part 13 includes: a charging circuit 135, a second switching device 131', an ignition capacitor 136, a second ignition primary coil 132', a first Two ignition secondary coils 133' and a second diode 137'. The charging circuit 135 is connected between the pulse control unit 112 and one end of the ignition capacitor 136 to charge the ignition capacitor 136 , and the pulse control unit 112 controls the charging circuit 135 to charge the ignition capacitor 136 by sending out a second pulse signal. The second switching device 131' can be a silicon-controlled rectifier element, connected between the pulse control part 112 and the one end of the ignition capacitor 136, and realizes on / off according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com