Outer-of-face deformation fatigue test loading device for web gap at position of steel bridge horizontal gusset plates

A fatigue test and loading device technology, applied in the direction of applying repetitive force/pulse force to test the strength of materials, etc., can solve the problem of difficult to reflect the external deformation and force of horizontal gusset plate, model manufacturing, installation time-consuming and laborious, segmental Due to the large size of the test piece, the results of the fatigue test are accurate, easy to disassemble, and highly replaceable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

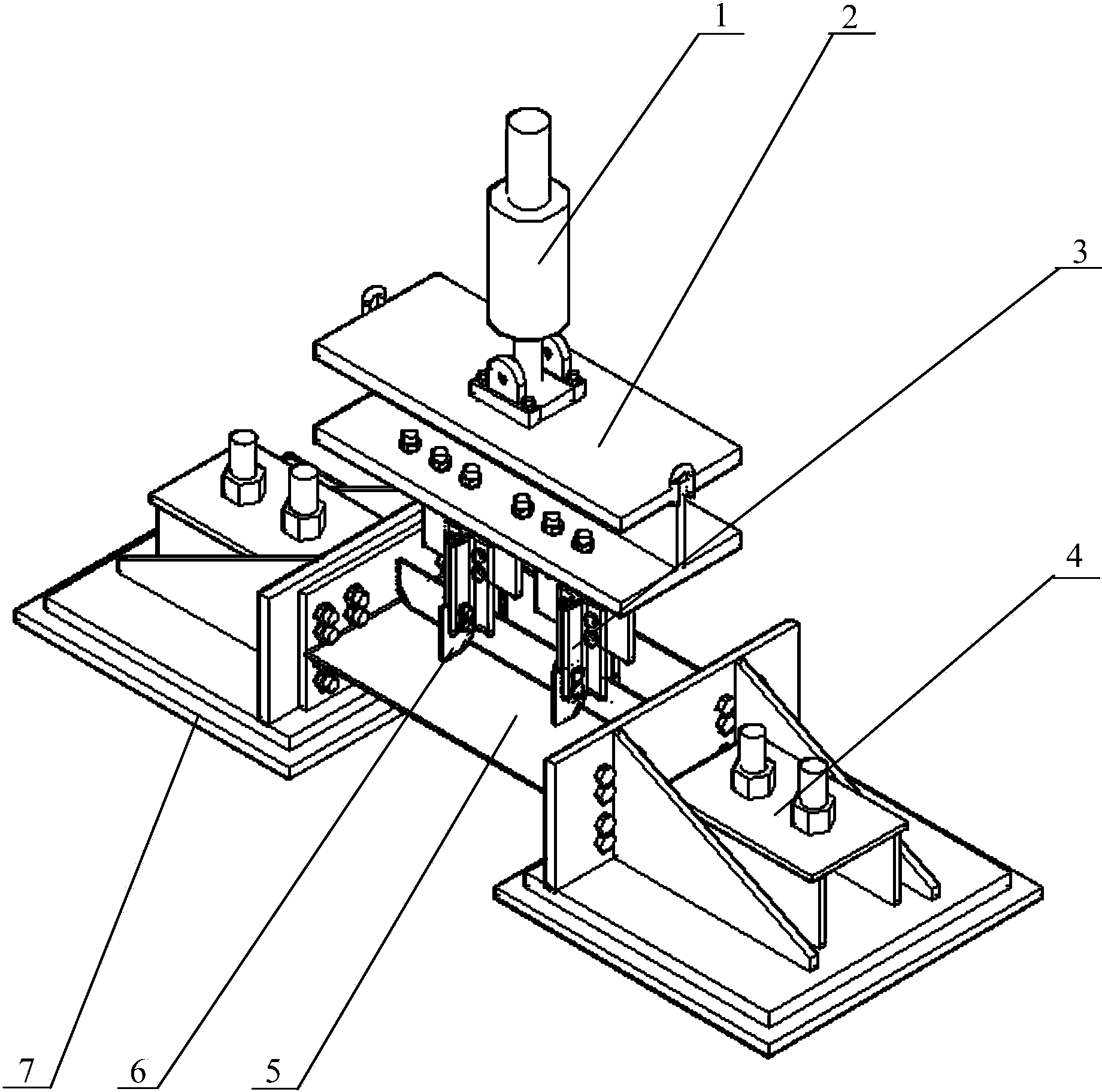

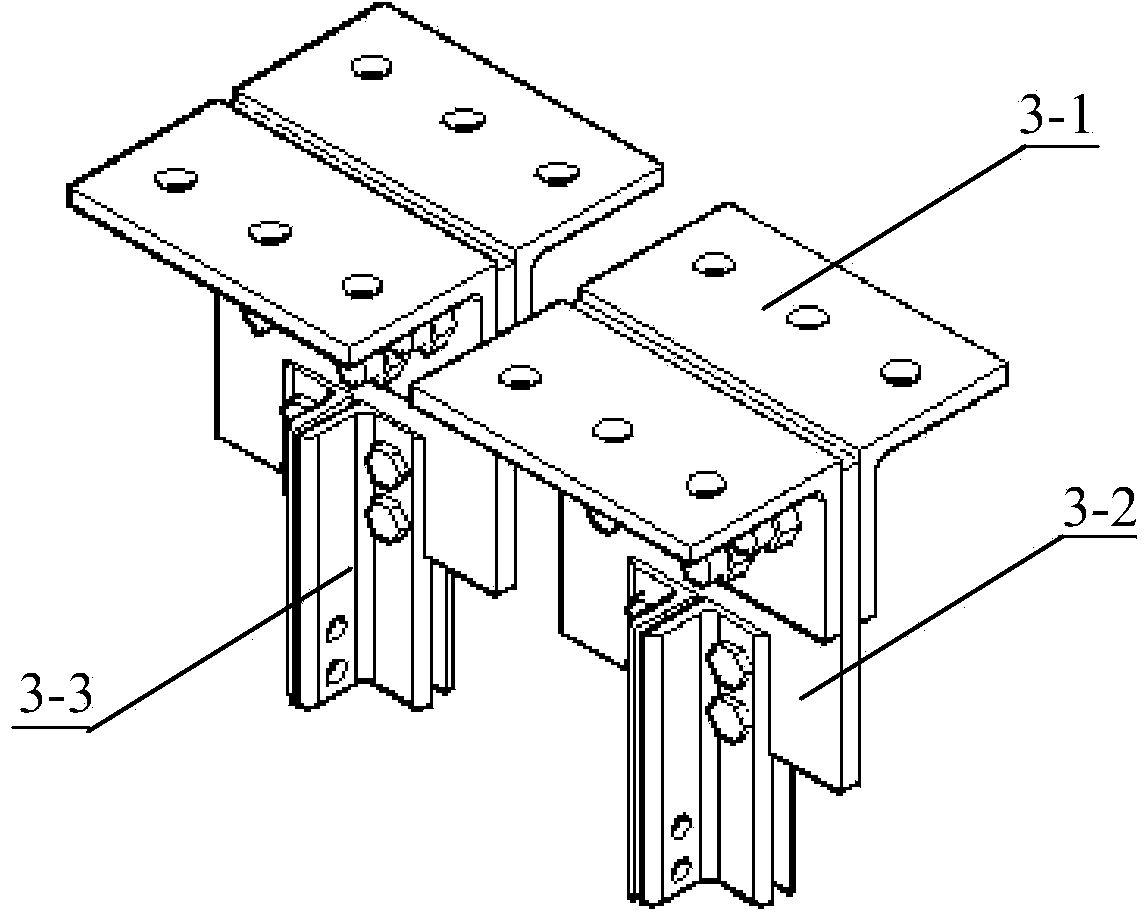

[0028] Such as figure 1 As shown, the loading device for out-of-plane deformation fatigue test of the web gap at the steel bridge horizontal gusset plate of this embodiment is composed of a servo-hydraulic actuator 1, a loading beam 2, a connection assembly 3, a ground anchor 4, and a force-transmitting horizontal gusset plate. 6 and 7 concrete leveling layer.

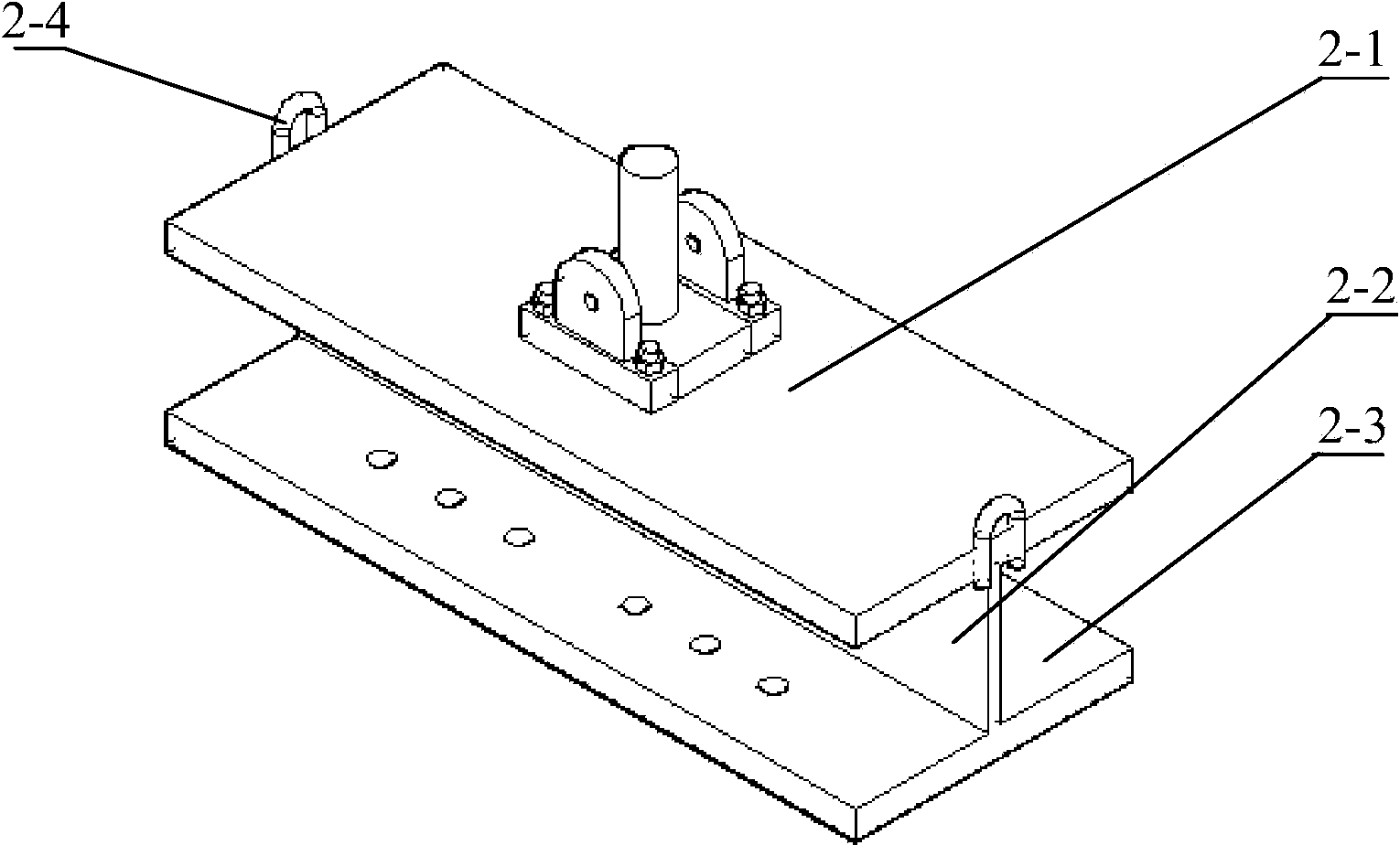

[0029] The loading beam 2 of this embodiment is an I-shaped beam welded from steel plates, see figure 2 The upper flange 2-1 is a rectangular steel plate with a width of 400mm, a thickness of 40mm, and a length of 1000mm. The load beam web 2-2 is a rectangular steel plate with a width of 200mm, a thickness of 20mm, and a length of 1000mm. The lower wing The edge plate 2-3 is a rectangular steel plate with a width of 400 mm, a thickness of 40 mm, and a length of 1000 mm. It has the same geometry and dimensions as the upper flange plate 2-1 and is symmetrical with respect to the load beam web 2-2. In order to temporarily f...

Embodiment 2

[0038] The upper flange plate 2-1 of the loading beam 2 in this embodiment is a rectangular steel plate with a width of 250 mm, a thickness of 16 mm, and a length of 500 mm. The load beam web 2-2 is a width of 100 mm, a thickness of 12 mm, and a length of 500 mm. Rectangular steel plate, the lower flange plate 2-3 is a rectangular steel plate with a width of 250mm, a thickness of 16mm and a length of 500mm.

[0039] The horizontal top plate of the steel anchor box 4-1 of this embodiment is a rectangular plate with a width of 250 mm, a thickness of 18 mm, and a length of 300 mm, and the vertical wing plate is a rectangular plate with a width of 150 mm, a thickness of 16 mmm, and a length of 400 mm.

[0040] In this embodiment, the port where the force-transmitting horizontal gusset plate 6 is connected to the stiffener and the web is processed with an isosceles triangle through welding hole with a right-angle side of 20 mm.

[0041] The other components and their connection relationsh...

Embodiment 3

[0043] The upper flange plate 2-1 of the loading beam 2 of this embodiment is a rectangular steel plate with a width of 550mm, a thickness of 60mm and a length of 1500mm. The web 2-2 of the loading beam is a width of 500mm, a thickness of 24mm, and a length of 1500mm. Rectangular steel plate, the lower flange plate 2-3 is a rectangular steel plate with a width of 550mm, a thickness of 60mm, and a length of 1500mm.

[0044] The horizontal top plate of the steel anchor box 4-1 of this embodiment is a rectangular plate with a width of 400 mm, a thickness of 24 mm, and a length of 800 mm, and the vertical wing plate is a rectangular plate with a width of 450 mm, a thickness of 22 mmm, and a length of 600 mm.

[0045] The port where the force-transmitting horizontal gusset plate 6 is connected to the stiffener and the web is processed with an isosceles right-angled triangle through-welding hole with a right-angle side of 80 mm.

[0046] The other components and their connection relationsh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com