Automatic sample feeding device for detecting chemical oxygen demand of water quality

An automatic sampling and water quality chemistry technology, applied in the field of sampling system, can solve the problem of unguaranteed sampling accuracy, and achieve the effect of avoiding pollution and corrosion, avoiding human error, and improving sampling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

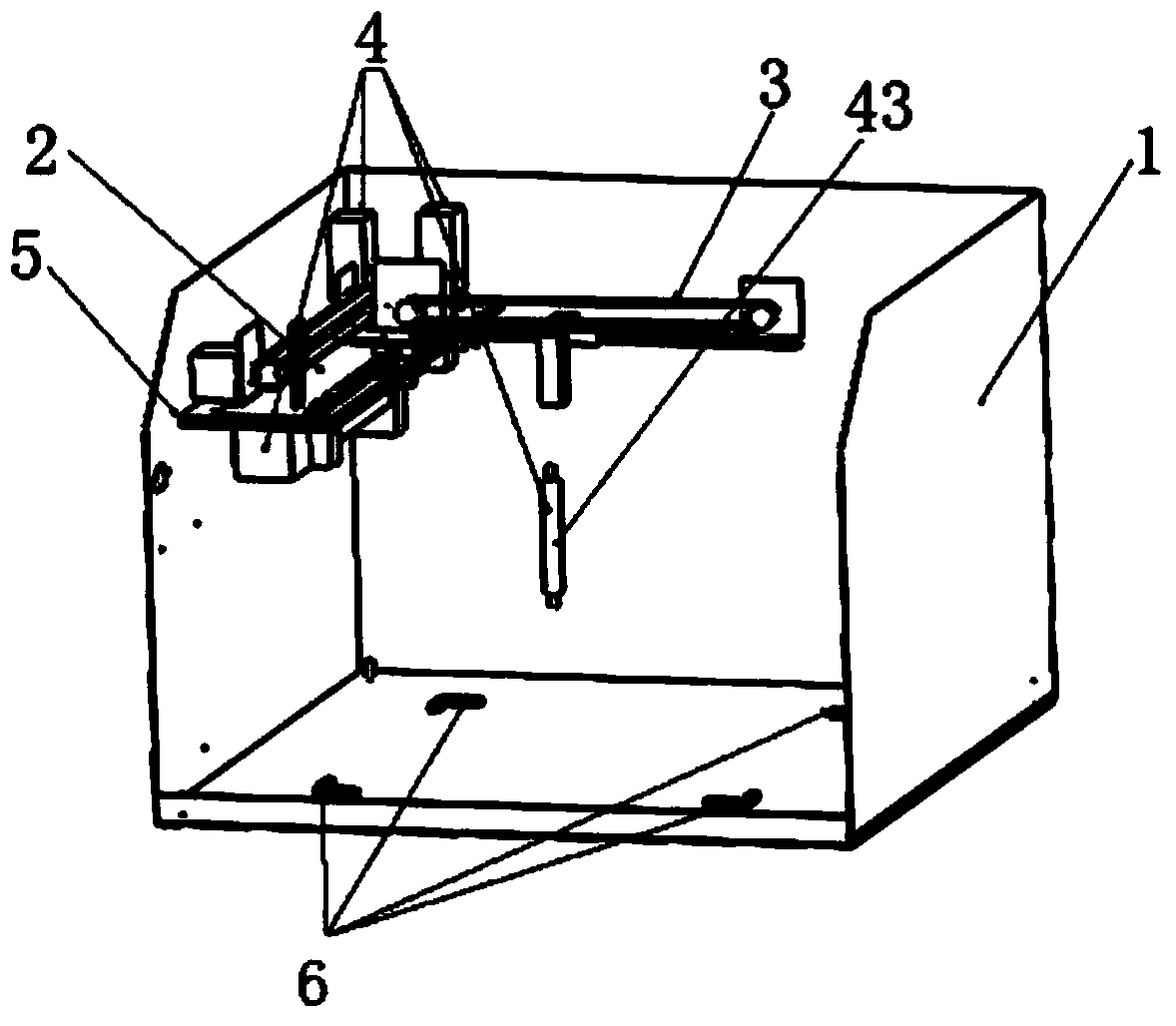

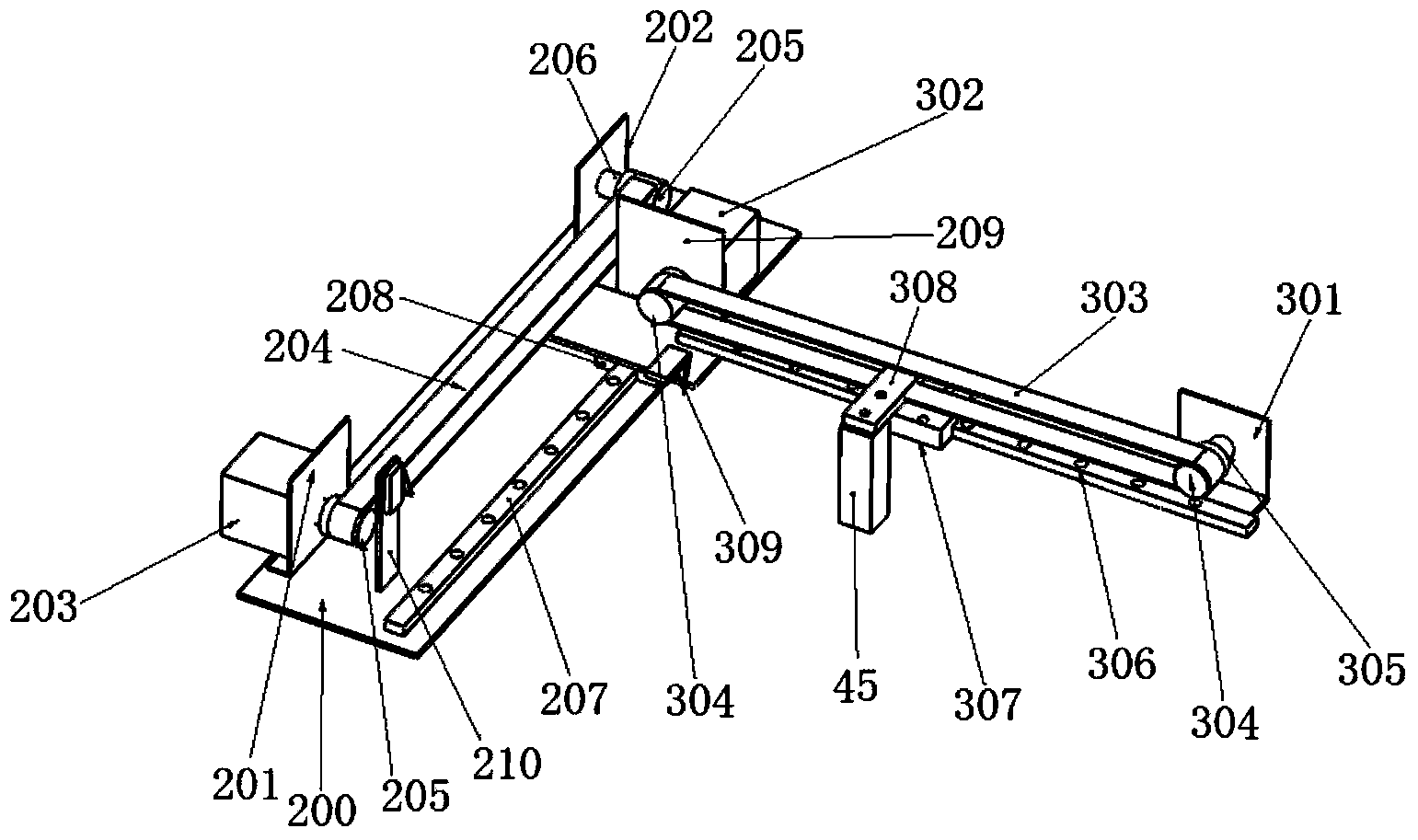

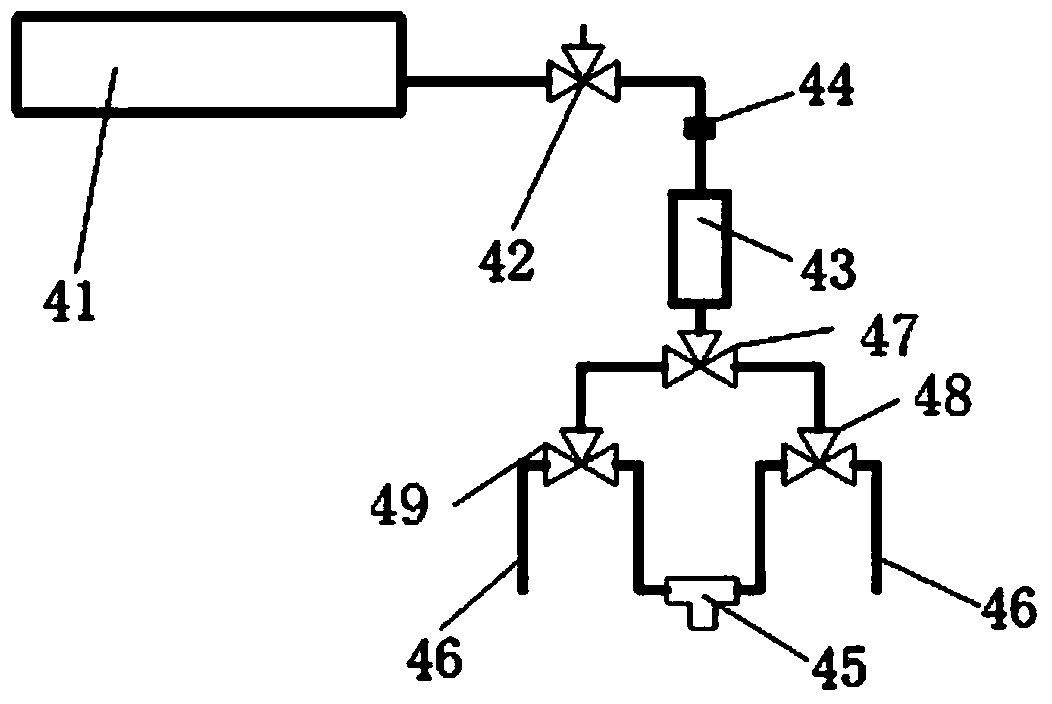

[0037] The automatic sampling device used for the detection of chemical oxygen demand of water quality in this embodiment can realize two ways of liquid feeding, mainly for the two reagents required for detection of chemical oxygen demand of water quality: potassium dichromate and concentrated sulfuric acid. After the device is powered on, 1 to 16 different sample injection test tubes can be set. After the setting is completed, according to the actual detection needs, 10ml potassium dichromate and 30ml concentrated sulfuric acid are sequentially injected into each test tube. The device can complete the sampling of 16 test tubes within 19 minutes, the sampling error is less than 1ml, and the sampling accuracy is within 2.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com