Improved flexible fireproof cable

A fireproof cable, an improved technology, applied in the field of power cables, can solve the problems affecting the bending radius of the cable, achieve the effect of maintaining the integrity of the line, avoiding short circuits, and improving the fire protection level and fire resistance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

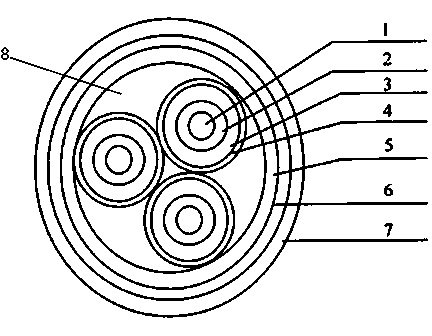

[0013] Such as figure 1 As shown, an improved flexible fireproof cable according to the present invention includes a cable core. Layer 8, the cable core is wrapped with a fireproof flame retardant layer 5, a second fireproof isolation layer 6 and a low-smoke halogen-free sheath layer 7; The insulating layer 2, the first fireproof isolation layer 3 and the color separation insulating layer 4 are composed.

[0014] The manufacturing method of this cable is to wrap several layers of mica tape on the conductor of the cable by wrapping, wrapping or extruding ceramic silicon rubber material on the mica tape as a fireproof insulating layer, and then extruding the insulating material The color-separation insulating layer is composed of a high flame-retardant material to wrap the flame-retardant structure layer after cable formation, and ceramic silicone rubber material is used to wrap or extrude the fire-proof isolation layer before extruding the sheath, and finally extrude the low-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com