Radio frequency module forming method

A radio frequency module and radio frequency integrated chip technology, applied in the field of radio frequency identification, can solve the problems of large area occupied by radio frequency modules and low production efficiency, and achieve the effect of improving integration, saving production costs, and realizing mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

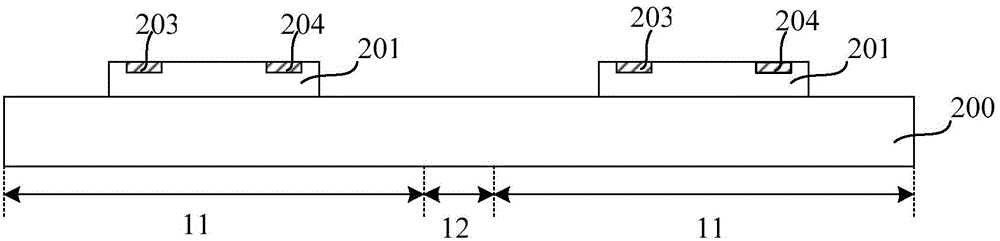

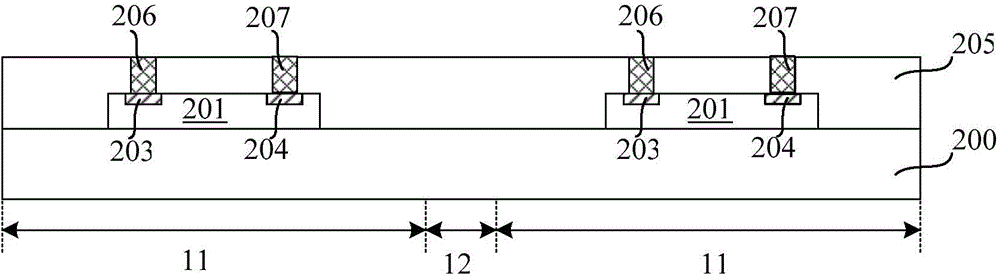

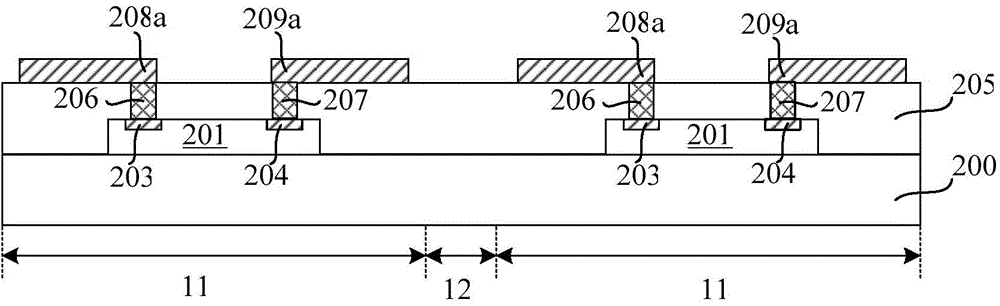

[0027] As mentioned in the background, the radio frequency module formed in the prior art occupies a relatively large area and has low manufacturing efficiency.

[0028] After research, in the existing technology, when forming a radio frequency module, the radio frequency identification antenna and the radio frequency integrated chip are manufactured separately. The metal connection wire is formed by the bonding process to electrically connect a single RFID antenna and the RF integrated chip to form a radio frequency module, which reduces the production efficiency, and the RFID antenna and the RF integrated chip need to be pasted on the carrier board and then electrically connected through a metal wire, so that the formed The radio frequency module occupies a relatively large area and volume.

[0029] After further research, the radio frequency identification antenna needs to meet a certain length when used and designed, so the size of the radio frequency identification antenn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com