Speed sensorless control method for doubly-fed wind turbine generator system

A speed sensorless, doubly-fed wind power generation technology, applied in motor generator control, electronic commutation motor control, and generator control, etc., can solve the problems of difficult implementation, high price, and complicated installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

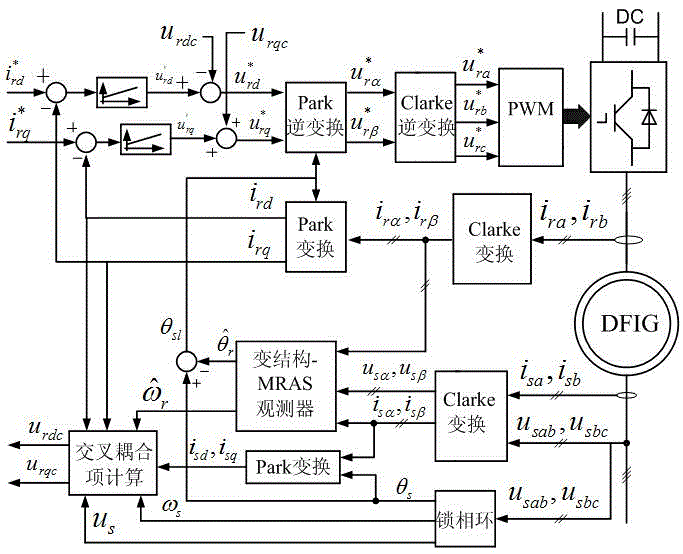

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

[0030] The invention of this patent is based on the following:

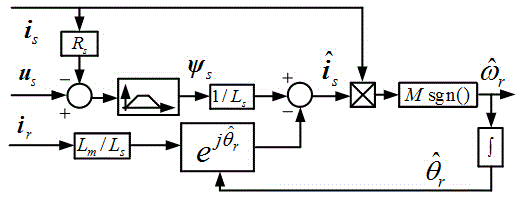

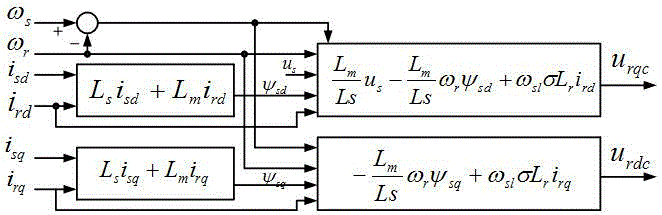

[0031] (1) The main idea of variable structure model reference self-adaptive identification of speed is to use the stator current measurement value as a reference model, the stator current adjustable model is obtained from the stator flux linkage and rotor current, and the cross product of the two model outputs is used to form a sliding model On the surface, the speed of the doubly-fed wind turbine is obtained through the sliding mode algorithm, and the integral operation is performed to obtain the electrical angle of the rotor, and then the estimated angle is used to modify the parameters of the adjustable model and participate in the vector transformation of the doubly-fed generator, so that the random The speed of the actual system with the influence of uncertainty factors can track the given speed, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com