Plant culture frame

A technology for cultivation racks and plants, applied in the field of plant cultivation racks, can solve the problems of waste of water resources, poor cooling effect, and poor control of the amount of access, and achieve the effects of saving water resources and good cooling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

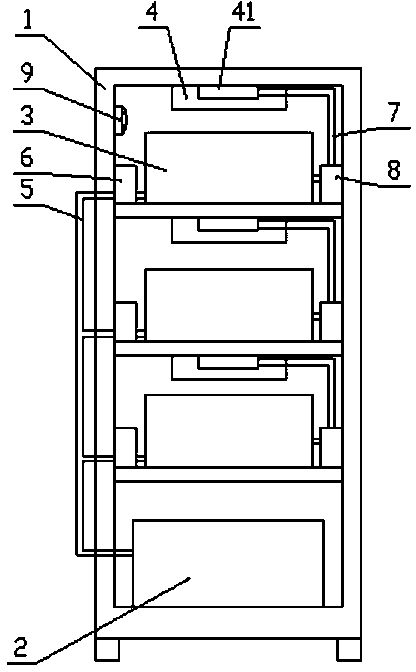

[0020] This embodiment provides a plant cultivation frame, such as figure 1 As shown, the plant cultivation frame includes a frame 1, which is divided into four space layers by partitions from top to bottom, the bottom space layer is provided with a nutrient solution tank 2, and the other three space layers are provided with plant cultivation Box 3, LED lighting lamp 4 is installed on the top of the space layer that is provided with plant cultivation box 3. A heat sink 41 is arranged on the LED lighting lamp 4 , and a cooling water channel is provided in the heat sink 41 .

[0021] Each plant cultivation box 3 communicates with the nutrient solution tank 2 through the liquid inlet pipeline 5, and the first water pump 6 is arranged on the liquid inlet pipeline 5, and each plant cultivation box 3 communicates with the heat sink 41 through the liquid outlet pipeline 7. The inlets of the cooling water channels are connected, and the second water pump 8 is arranged on the outlet p...

Embodiment 2

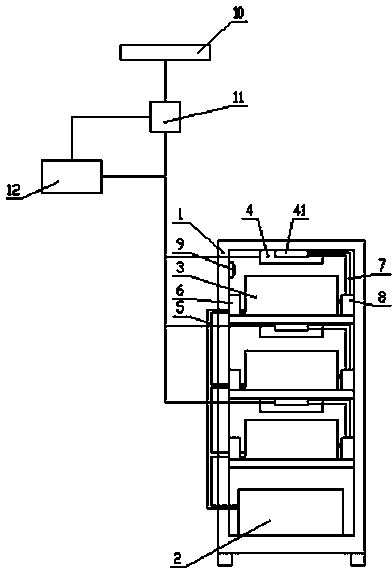

[0028] This embodiment provides a plant cultivation frame, such as figure 2 As shown, the structure of the plant cultivation frame is basically the same as that of Embodiment 1, including a frame 1, which is divided into four space layers by partitions from top to bottom, the bottom space layer is provided with a nutrient solution tank 2, and the other three Each space layer is provided with a plant cultivation box 3, and an LED lighting lamp 4 is installed on the top of the space layer provided with the plant cultivation box 3. A heat sink 41 is arranged on the LED lighting lamp 4 , and a cooling water channel is provided in the heat sink 41 . Each plant cultivation box 3 is connected with the nutrient solution tank 2 through the first water pump 6 , and connected with the cooling water channel in the heat sink 41 through the second water pump 8 .

[0029] The difference is that the plant cultivating frame of this embodiment also includes a photovoltaic solar panel 10 insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com