Method for washing CPF-PT series type melt filters

A CPF-PT, melt filter technology, applied in the field of cleaning, can solve the problems of uneven temperature, difficult cleaning, cleaning effect difficult to meet the requirements of high-quality fiber production, etc., to achieve the effect of convenient operation and pollution-free

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

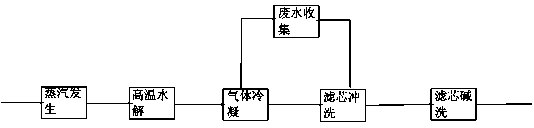

[0022] A cleaning method for CPF-PT series melt filter includes the following steps:

[0023] (1) Steam is generated. After the saturated steam is heated by the steam heater, the temperature reaches 320-350℃;

[0024] (2) High-temperature hydrolysis: first confirm that the valve for entering and exiting the melt in the cleaned filter chamber is closed, the drain valve has been opened and the melt that can be drained in the filter chamber cavity has been drained, and then the drain valve is closed, and the hot steam in and out is opened. The valve introduces 0.3MPa saturated hot steam into the filter chamber to hydrolyze the polymer for 2-4 hours. The direction of the steam passing through the filter layer is opposite to the path of the polymer filtration;

[0025] The hydrolysis degrades the polymer molecular chain and decomposes into the initial components of PET (terephthalic acid and ethylene glycol). The ethylene glycol vaporizes at about 280°C, and the terephthalic acid sublimat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com