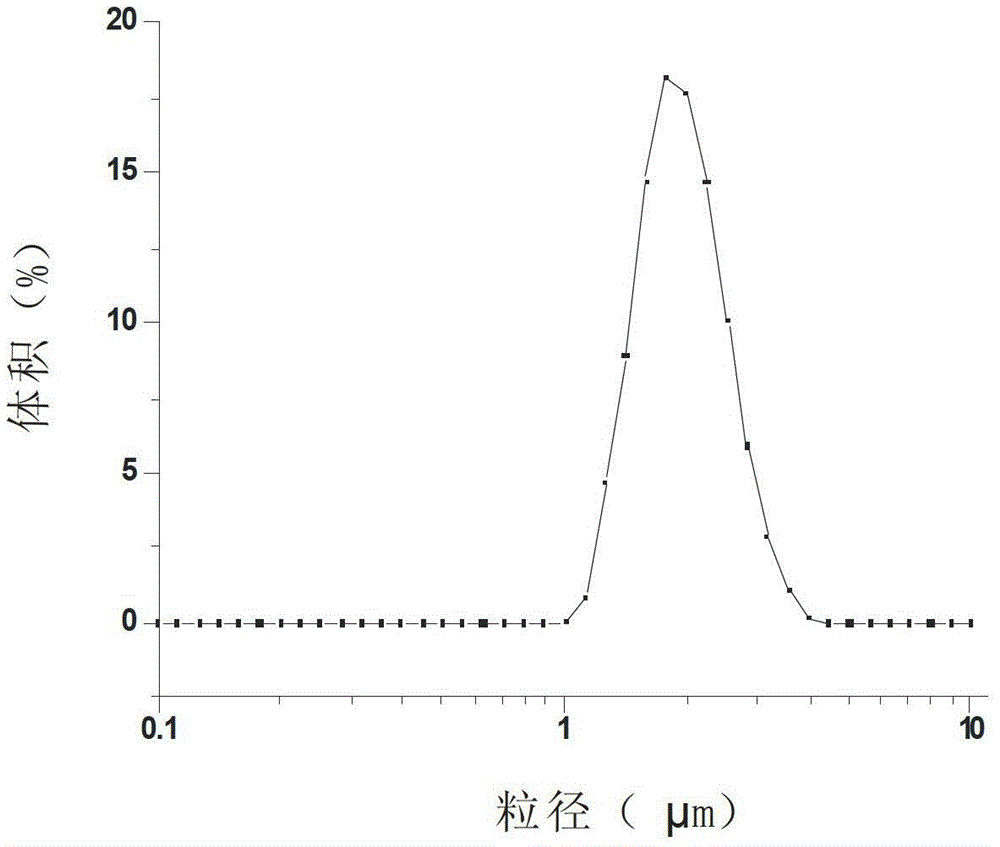

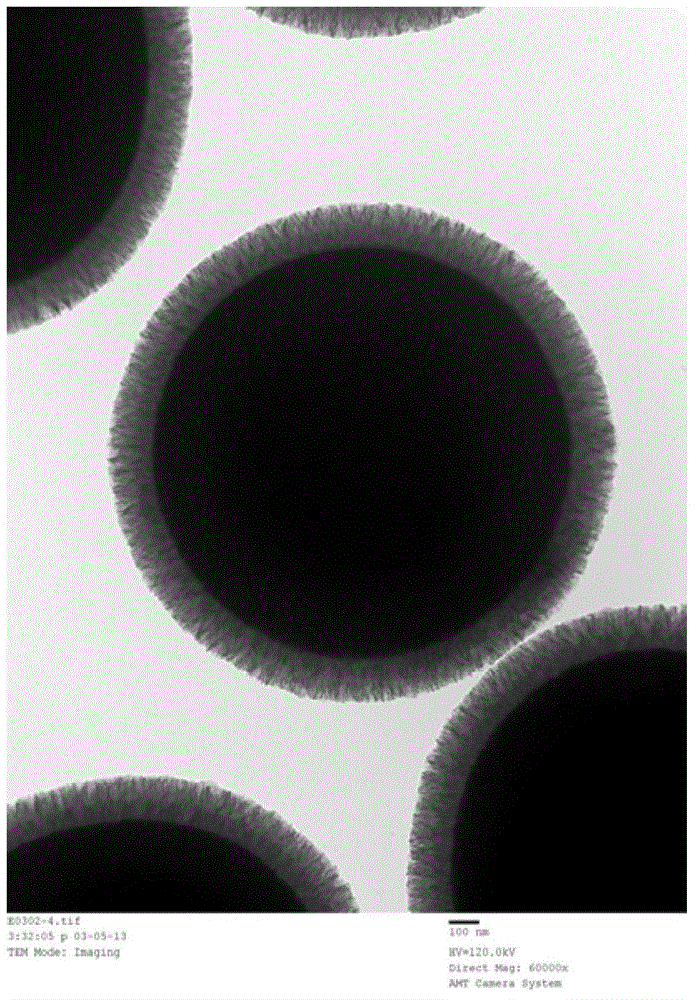

A silica gel chromatography packing with ordered mesoporous core-shell structure and its preparation and application

A core-shell structure, silica gel chromatography technology, applied in the field of analytical chemistry, can solve problems such as difficulty in meeting the needs of chromatographic separation, and achieve the effects of controllable particle size, good reproducibility, and high chromatographic column efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

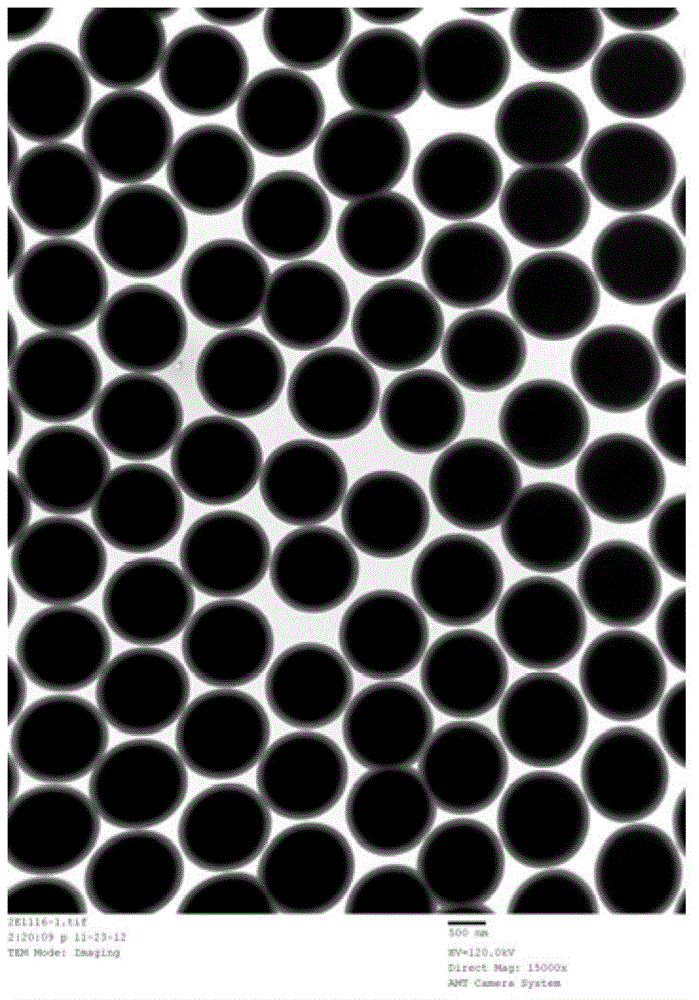

[0030] Non-porous silica gel synthesis

[0031] First prepare the hydrolyzate, 6.70ml of ammonia water (28-30wt.%, Sigma-Aldrich), 5.13ml of water, 69.55ml of absolute ethanol, stir mechanically in a water bath at 22°C; quickly add 4ml of ethyl orthosilicate to the hydrolyzate Esters (98%, Sigma-Aldrich), start the reaction, after 40min, raise the temperature of the water bath to 55°C, add 0.64ml of water and 4ml of ethyl orthosilicate, the ethyl orthosilicate must be preheated at 55°C in advance, the reaction 40min. After adding 0.64ml of water and 4ml of ethyl orthosilicate repeatedly for 3 times, add the hydrolyzate again (6.7ml of ammonia water (28-30wt.%, Sigma-Aldrich), 5.13ml of water, 69.55ml of absolute ethanol), and continue to add 0.64 ml water and 4 ml tetraethyl orthosilicate to grow to target particle size. After growing 7 layers, the synthetic non-porous silica gel was centrifuged and washed at 3000 rpm for 5 min, washed three times with ethanol and twice with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com