Composite catalyst and preparation method of composite catalyst as well as application of composite catalyst

A catalyst and composite technology, applied in the field of composite catalyst and its preparation, can solve the problems of application limitation, difficult solution, poor adhesion of carbon materials, etc., and achieve the effect of low equipment requirements, easy realization, and improved material adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

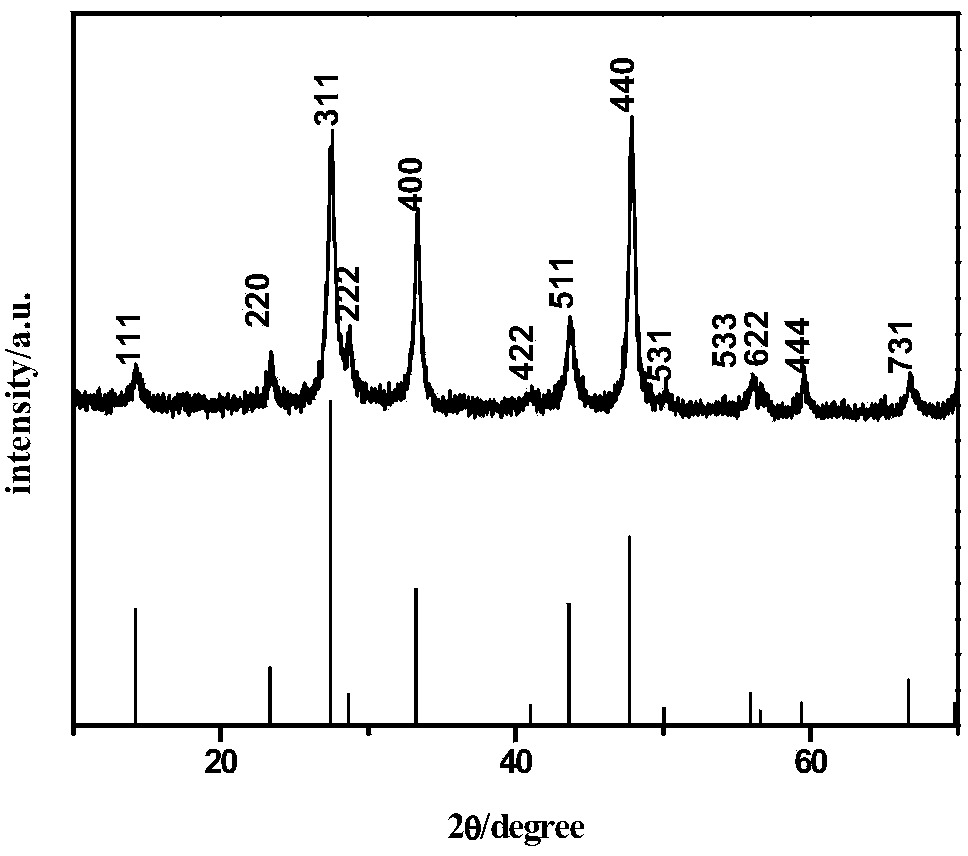

Image

Examples

Embodiment 1

[0034] A kind of In 2.77 S 4 The preparation method, the preparation method is: 0.6g InCl 3 Dissolve 0.8g of thioacetamide in 30mL of distilled water, then add 30mL of n-butanol and 2mL of Span 80, stir and mix evenly, first transfer it into a polytetrafluoroethylene sleeve, then put it into a high-pressure reactor and seal it, and react at 150°C After 24 hours, cool to room temperature naturally, wash the precipitate three times with absolute ethanol and distilled water, and dry at 60°C.

Embodiment 2

[0036] A kind of In 2.77 S 4 The preparation method of / C composite catalyst, described preparation method is: the In that 0.2g embodiment 1 obtains 2.77 S 4 Ball mill with 5mL of isopropanol to obtain solution I, and ball mill 0.2g of conductive carbon with 5mL of isopropanol to obtain solution II, and mix solution I and solution II at a mass ratio of 1:4.

Embodiment 3

[0038] The difference with embodiment 2 is:

[0039] Mix solution I and solution II at a mass ratio of 1:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com