A kind of cu3sns4 nanomaterial counter electrode for dye-sensitized solar cell and preparation method thereof

A technology of solar cells and dye sensitization, which is applied in the field of nanomaterials and solar cells, can solve the problems of high price, unfavorable industrial production of dye-sensitized solar cells, and reduced battery efficiency, and achieves strong corrosion resistance and excellent manufacturing process. Simple and sophisticated effect with low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 2

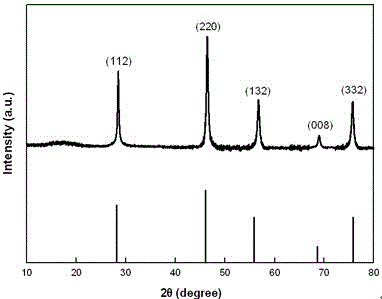

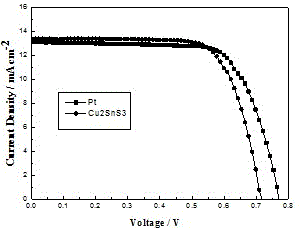

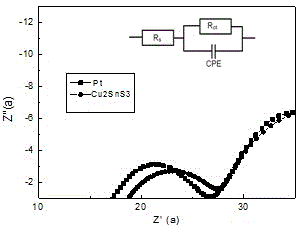

[0026] Example 1 Titanium dioxide nanoporous membrane-based Cu3SnS4 counter electrode dye-sensitized solar cell

[0027] The specific steps of the preparation method of the new structure of the dye-sensitized solar cell in this embodiment are as follows:

[0028] (1) Photoanode preparation: take a piece of conductive glass (FTO), and cut it into glass pieces of the required size with a glass knife. Put the conductive glass into a mixed solution of acetone, isopropanol, and deionized water (volume ratio v1:v2:v3=1:1:1) and ultrasonically clean it for 30 minutes, then dry it with nitrogen. A titanium dioxide porous film was coated on the conductive surface by spin coating, and annealed at 450 °C for 1 h. The photoanode can be prepared by immersing the sample in 3mM di-tetrabutylammonium-bis(isothiocyano)bis(2,2'-bipyridyl-4,4'-dicarboxy)ruthenium (N719) solution for 24h.

[0029] (2) Counter electrode preparation: Dissolve Cu3SnS4 nanoparticles in deionized water (0.05g / mL), a...

Embodiment 2 2

[0034] Example 2 Titanium dioxide nanotube-based Cu3SnS4 counter electrode dye-sensitized solar cell The specific steps of the preparation method of the new structure of the dye-sensitized solar cell in this embodiment are as follows:

[0035](1) Preparation of titanium dioxide nanotubes: A piece of titanium foil (0.25 mm, 99.6%) was soaked in acetone, isopropanol, and deionized water, ultrasonically cleaned for 15 min, and dried with nitrogen. The titanium foil and the platinum counter electrode were placed in parallel in a two-electrode system for anodic oxidation reaction, in which the electrolyte was ethylene glycol containing 2vol% deionized water and 0.25wt% ammonium fluoride, the input voltage was a constant voltage of 60V, and anodized for 3h The final sample was rinsed and dried with nitrogen, placed in a muffle furnace for annealing at 450°C for 1 hour, and the sample was taken out for the second anodic oxidation for 1 hour (other conditions are the same as the first ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com