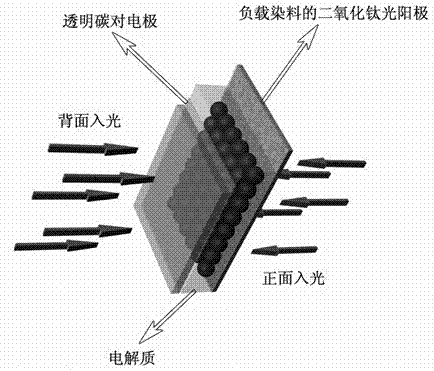

Preparation method of transparent carbon electrode in dye sensitization solar battery

A technology of solar cells and dye sensitization, which is applied in the field of preparation of transparent carbon electrodes, can solve the problems of complex preparation process, difficulty in achieving transparency, and low production cost, and achieve simple preparation process, low cost of raw materials, and reduced battery cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

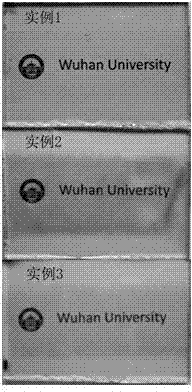

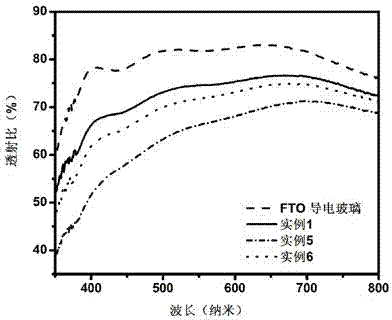

example 1

[0024] Dissolve 2mL of acetylacetone in 2mL of isopropanol, and then add 2mL of Triton X-100 to it. After the mixed solution is stirred evenly, drop it drop by drop on the FTO conductive glass fixed on the homogenizer. After the FTO conductive glass is full, start to shake the glue. The parameters of the glue throwing process are set as follows: low speed: 400rpm / min, high speed: 1600rpm / min. Put the FTO conductive glass that has been glued off into a tube furnace and sinter at 500°C for 0.5h under the condition of argon.

example 2

[0026] Dissolve 2mL of acetylacetone in 2mL of isopropanol, and then add 1mL of Triton X-100 to it. After the mixed solution is stirred evenly, drop it drop by drop on the FTO conductive glass fixed on the homogenizer. After the FTO conductive glass is full, start to shake the glue. The parameters of the glue throwing process are set as follows: low speed: 400rpm / min, high speed: 1600rpm / min. Put the FTO conductive glass that has been glued off into a tube furnace and sinter at 500°C for 0.5h under the condition of argon.

example 3

[0028] Dissolve 2 mL of acetylacetone in 2 mL of isopropanol, and then add 0.4 mL of Triton X-100 to it. After the mixed solution is stirred evenly, drop it drop by drop on the FTO conductive glass fixed on the homogenizer. After the FTO conductive glass is covered, start to throw the glue. The parameters of the glue throwing process are set as follows: low speed: 400rpm / min, high speed: 1600rpm / min. Put the FTO conductive glass that has been glued off into a tube furnace and sinter at 500°C for 0.5h under the condition of argon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com