A kind of cu for photoelectrochemical solar cell 3 sns 4 /cu 2 snse 3 Composite photocathode and preparation method thereof

A solar cell and photoelectrochemical technology, applied in the fields of nanomaterials and solar cells, can solve problems such as unsatisfactory conversion efficiency, and achieve the effects of simple manufacturing process, simple and safe preparation process, and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

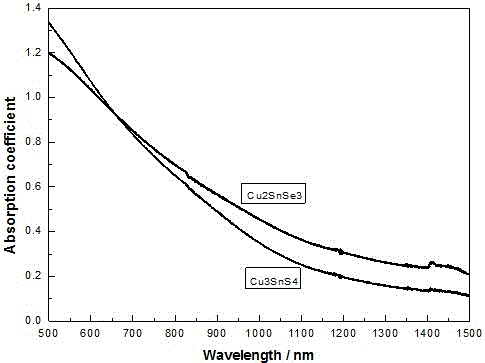

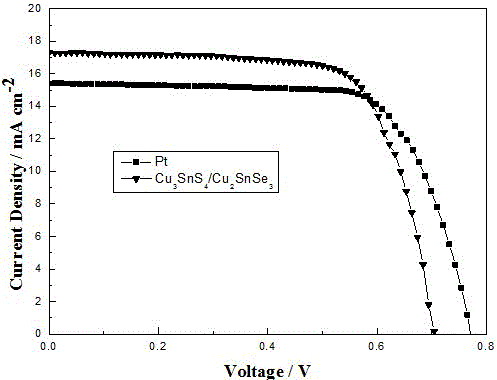

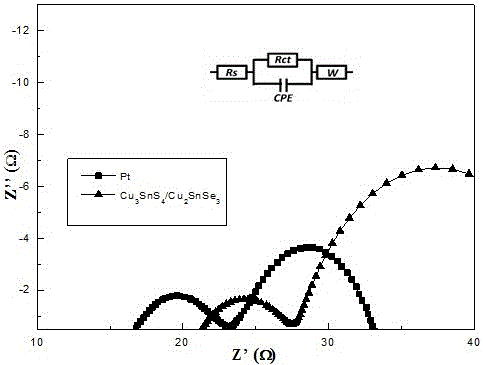

[0028] Example 1 TiO2 Nanoporous Membrane-based Cu3SnS4 / Cu2SnSe3 Composite Photocathode Photoelectrochemistry

[0029] Solar battery

[0030] The concrete steps of the preparation method of the photoelectrochemical solar cell new structure of embodiment are as follows:

[0031] (1) Photoanode preparation: take a piece of conductive glass (FTO), and cut it into glass pieces of the required size with a glass knife. Put the conductive glass into a mixed solution of acetone, isopropanol, and deionized water (volume ratio v1:v2:v3=1:1:1), ultrasonically clean it for 30 minutes, and dry it with nitrogen. A titanium dioxide porous film was coated on the conductive surface by spin coating, and annealed at 450 °C for 1 h. The photoanode can be prepared by immersing the sample in 3mM di-tetrabutylammonium-bis(isothiocyano)bis(2,2'-bipyridyl-4,4'-dicarboxy)ruthenium (N719) solution for 24h.

[0032] Preparation of composite photocathode: Dissolve Cu3SnS4 nanoparticles in deionized wat...

Embodiment 2

[0037] Example 2 Titanium dioxide nanotube based Cu3SnS4 / Cu2SnSe3 photocathode photoelectrochemical solar cell

[0038] The specific steps of the preparation method of the photoelectrochemical solar cell new structure of the present embodiment are as follows:

[0039] (1) Preparation of titanium dioxide nanotubes: Take a piece of titanium foil (0.25 mm, 99.6%), soak it in acetone, isopropanol, and deionized water, ultrasonically clean it for 15 minutes, and dry it with nitrogen. The titanium foil and the platinum photocathode were placed in parallel in a two-electrode system for anodic oxidation reaction, in which the electrolyte was ethylene glycol containing 2vol% deionized water and 0.25wt% ammonium fluoride, the input voltage was 60V constant voltage, anodized for 3h The final sample was rinsed and dried with nitrogen, placed in a muffle furnace for annealing at 450°C for 1 hour, and the sample was taken out for the second anodic oxidation for 1 hour (other conditions were...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com